In this section of the website we explain Anaerobic Digestion Plants by country and the progress in recent years which has been made in the implementation of AD technology in each. For convenience we have split each country into a page, as listed and linked below:

Anaerobic Digestion Plants UK

Anaerobic Digestion Plants Scotland

Anaerobic Digestion Plants in Ireland

Anaerobic Digestion in China

Anaerobic Digestion in Ukraine

Popular Types of Biogas Plant

Cost of Anaerobic Digestion Plant

In all the subject nations there has been a substantial rise in the number of operating AD facilities of all types.

Types and Capabilities of Anaerobic Digestion Plants

AD Plants in the Municipal Solid Waste Sector

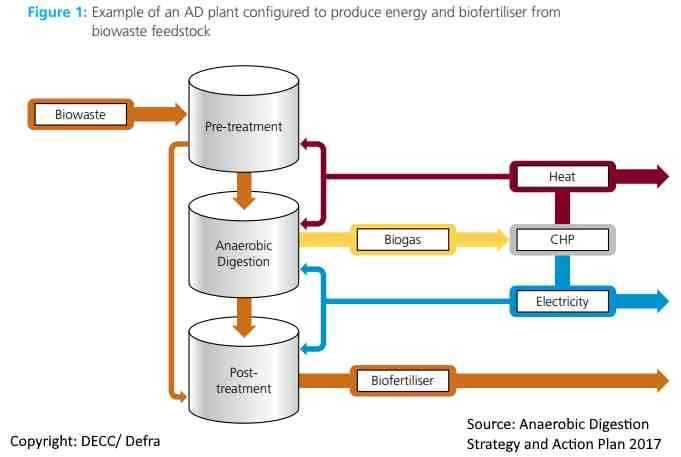

To appreciate the very wide scope for anaerobic digestion of Municipal Solid Waste (MSW) “putrescible fractions”, becomes clear when thought is given to the composition of household refuse. Think just how far existing recycling techniques can be improved by using this biowaste. The big advantage possessed when an anaerobic digestion plant is installed is that it produces “biogas”. That biogas can be:

- a fuel for ordinary diesel engine electrical generators, and

- it also can be converted into biofuel which can be used as a transport fuel in the motor industry.

This can in the future (and forever), provide society with a green fuel to replace fossil fuels.

Anaerobic Digestion Plants for MSW processing are still a technology that needs a lot of improvement and development.

There are a lot of details that will always need to be fine-tuned for these plants to work reliably for the fermentation of wastes. But, the sector is remarkably young.

For example, the most common MSW biogas plant technology is no more than 15 years old (2015). Anaerobic Digestion has been used for sewage sludge digestion at wastewater treatment works for at least 70 years, but its adoption for municipal waste management is far more recent.

Why is Hydrogen Production from MSW Anaerobic Digestion Never Considered as Fuel?

Hydrogen is produced during the anaerobic digestion process. But is rarely seen in the biogas because once it is generated it is soon re-used biologically in any one of many biological pathways.

Hydrogen is produced during the anaerobic digestion process. But is rarely seen in the biogas because once it is generated it is soon re-used biologically in any one of many biological pathways.

If a search is done for “biohydrogen” in any leading web search engine. Many references will appear.

The basic rule is that as the pH falls and the process becomes acidic, more hydrogen will be present in the biogas. So, some would say:

“Why not optimize the process plant at a low pH, make more hydrogen and extract that as a fuel?”

The reason why this would not be a good idea lies in the economics of this and the stability of the operation of any biogas plant at the necessary low pHs.

For one thing, producing hydrogen pretty much always interferes with methane production.

In addition, the amount of energy that would be collectable as a result, within the hydrogen, would not be enough for the idea to be viable.

Anaerobic Digestion Plants Outside the Municipal Solid Waste Sector

Recent improvements in Anaerobic digestion plant design outside the MSW sector have also been appearing in quick succession in recent years.

There have been numerous patented developments in the anaerobic digestion process, and some of these are often called Advanced Anaerobic Digester Systems (AADSs), and come in various guises:

- Hybrid Systems/ Plants; Some of which manage to be both “fully mixed” and “continuous-process plug-flow designs” at different stages of the digestion process.

- Plants that are highly automated, require very few staff to operate them despite their large size, and which are consequently much lower in their annual operating costs.

- Anaerobic Digestion Plant systems for the agricultural sector have been developed which are also designed to be scalable from fifty Animal Unit installations, powering a 25kW rated generator, to Biogas generators rated at 20 Megawatts or more of continuous electrical generation.

- Plant system in which the improved application of programmable logic controllers (PLCs), in combination with local, reliable and off-the-shelf digital control system (DCS) software applications, is now available, and is leading to much higher AD Plant reliability and much better uptimes.

- AD Plants are also benefiting from scientific research into anaerobic bacteria populations, and their evolution under the changing stimuli of a biogas fermentation plant.

AD Plant Developments in the Industrializing Nations

In India, Nepal, Pakistan and Bangladesh biogas produced from the anaerobic digestion of manure is increasingly the norm in small scale digestion facilities. In India, biogas is called “gobar gas”, so to some extent due to the language used, this activity has been under-reported by the west until recently.

The investment effort has been and still is huge. It is estimated that “gobar gas” facilities are in use in over 2 million households in India. The number in Bangladesh exceeds 50,000, and there are also many thousands in Pakistan, particularly in the North Punjab region.

In the industrializing world, the digester is quite different from that used in the developed nations. It comprises an airtight circular pit constructed from concrete, plus suitable pipe connections.

Manure is drained into the pit, usually straight from the cattle shed, or pig stalls. Feeding is a daily chore when a charging vessel/ pit is filled with the necessary quantity of wastewater, and other organic wastes, and all are mashed up together by hand, before being fed into the reactor.

In general, the use of the biogas is simplicity itself, as the gas pipe is simply connected to the kitchen fireplace, with little more than control valves, and gas blow-back protection between the two. Nevertheless, the combustion of this biogas produces very little by the way of odour or smoke and is so much healthier than using open wood-fires that the benefits in health terms are self-evident and massive.

This simplicity in the implementation of anaerobic digestion in what only in the most generic way can be called “plants” in the western sense, and the use of cheap or free raw waste materials in villages, makes biogas use the most environmentally sound energy sources for rural needs, in hot countries where temperatures are high enough for this to work.

Anaerobic Digestion Plants for the Wastewater (Sewage Treatment) Sector

Energy is increasingly being recovered from sludge through Anaerobic Digestion Plants and methane gas production.

Incineration of dried sludge, which was the preferred method of sludge treatment starting in the 1970s, is being phased out in most countries, and new AD Plants are being built to replace old sludge incinerators. The US has now reached the halfway mark, with 50% of all wastewater treatment plants now having installed biogas plant capacity.

AD Plants Processing Dedicated Energy Crops

Anaerobic Digestion Plants processing dedicated energy crops can work well, and the best examples achieve very high levels of organic content degradation and biogas production. However, in most countries, subsidies for these crop-only fed plants are being phased out, due to concerns that they compete with crop used for food, and raise food prices.

Anaerobic Digestion Plants for Agricultural Use

In the agricultural sector of the developed nations slurry-only systems, are generally cheaper than plants built to also process crop waste and food waste, but unless a significant amount of food waste is used, generate far less energy than AD Plants fed by crops such as grass silage, and maize.

However, anaerobic digestion plants that are optimized in their energy output by using a limited amount of crop material (up to about 30%) is common, in the agricultural sector.

Some experts have even reported that the simple expedient of adding crop waste can increase energy output from a manure-only AD Plant tenfold.

It has been suggested that a 10 times increase can be achieved for only three times the capital cost when compared with a manure-slurry-only system.

The Prospect for Anaerobic Digestion Plants of the Future

In all the many sectors of activity of anaerobic digestion, there is wide scope for further technical improvements and the installation of additional capacity.

For example, the collection of food waste for use in anaerobic digestion is in its infancy in most developed nations and will require large increases in existing capacity.

The only possible area of contraction in the number of anaerobic digestion plants is in the use of these plants where they are fed solely by dedicated food crops.

The present trend in legislation for landfills is for the waste management industry to move ever more closely towards increased waste minimisation and to the eventual elimination of biodegradable waste sent to landfills.

It is the personal view held by the authors of this website that this is good news for the environment, and for society generally. Anaerobic digestion is ideal for the pre-treatment of organic waste for the production of biogas, and we hold the view that energy generation from landfills by collecting the biogas, comes a poor second.

Therefore, although landfill gas collection and utilization from all existing landfills remains a priority, the phasing out of organic waste disposal to landfills is to be welcomed.

The future for anaerobic digestion plants is bright!

You may also find our article on Anaerobic Digestion Plants in Scotland interesting here.

[Page originally created in November 2014. Page updated April 2021.]

The U.S. has an enormous amount of untapped potential for biogas from organic waste streams. There is much feedstock ready to use. What are the opportunities for using swine manure as an anaerobic digestion feedstock. has research been completed? You refer to manure, but what about swine manure, is the process the same as in dairy manure?

Interesting page, if a bit unfocused. I was looking for an answer to my particular question. “All landfills should have landfill gas collection…” Would you say that we could complain about our local landfill because they still have not got a flare running.

Biogas development gets heavily criticised, around my way, whenever there is a planning application. People say it uses food crops, but even if it does, and there are so many wastes here I doubt many will want to make biogas from crops. I don’t understand why it would matter as long as the AD plant crops were grown more efficiently and only amounted to the higher yield from a farm due to using better fertiliser etc., from the biogas plant digestate.

Do you need a Digester Rescue for an Anaerobic digester plant? Digester failures can be costly. The wrong feedstock can be detrimental to the methane-producing bacteria, and the digester will be producing too much gas or not enough. In some cases, the mix of feedstocks produces a gas that is more corrosive than a CHP can handle, leading to costly repairs. Whatever your AD plant problem we can help with a Digester Rescue. H Four Biogas Inc.

Interesting page, if a bit unfocused. I was looking for an answer to my particular question. “All landfills should have landfill gas collection…” Would you say that we could complain about our local landfill because they still have not got a flare running.

In a bio gas digester feeded by poultry layer litter, is it a good idea if spirulina algea is feeded for much better methane output ?

anyone knows if there is a chance to find somewhere the biogas digesters cost curves to have an estimation with the +-20% of accuracy?

Quite honestly, in my opinion you are asking the impossible from general estimated cost curves to get that degree of accuracy. The only way I know of to get that would be to obtain detailed quotations from biogas plant contractors, and then see if you can tie them down to a fixed-price contract.

Hi, I wonder what the biogas production curve (with methane content) looks like in one cycle in batch technology?

Does anybody here a good operational experience with batch technology in OFMSW processing? I am really worried about the fluctuation in biogas production and quality.

Katarina. I don’t have operational experience of Organic Fraction Municipal Solid Waste batch reactors. Can you tell us from what perspective you are concerned about the fluctuation in biogas production and quality.

Are you considering this from an economic point of view, an operational point of view, or maybe as an environmental concern if the initial low methane gas is vented to the atmosphere at the early stage of each batch cycle?

Global climate change experts have today been expressing the paramount need to reduce methane emissions as one of the biggest/ lowest-cost ways to rapidly reduce greenhouse gas emissions, and I think the factor now being quoted as the damage of a unit mass of methane versus carbon dioxide emissions – stating that methane is over 100 times more damaging in the atmosphere than CO2. If you have been reading that news I could well understand you might have concerns about the potential for fugitive methane emissions during batch technology OFMSW processing.

Is it possible to bottle biogas for home and commercial use in the same way as LPG is?

I wish the United States could learn from this, rather than wasting away 730 football stadiums worth of food per year.

Despite the fact that the terminology of natural gas remains the same, the biogas is far and away more natural than the same natural gas.