If you said that mesophilic anaerobic digestion is “cool”, you'd be right compared with the other common temperature range used for AD plants, but probably in more ways than you would realize!

The term mesophilic when referring to a biodigestor has been adopted by biogas plant designers to distinguish the two best temperature ranges for operating biogas reactors for the highest efficiency of operation.

Wikipedia Definition:

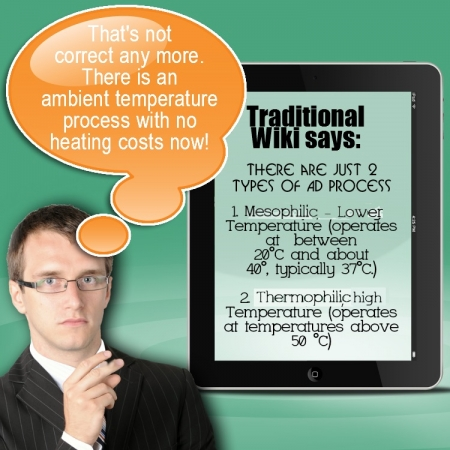

“The two conventional operational temperature levels for anaerobic digesters determine the species of methanogens in the digesters:

Mesophilic digestion takes place optimally around 30 to 38 °C, or at ambient temperatures between 20 and 45 °C, where mesophiles are the primary microorganism present.

Thermophilic digestion takes place optimally around 49 to 57 °C, or at elevated temperatures up to 70 °C, where thermophiles are the primary microorganisms present.” This is known as the mesophilic temperature anaerobic digestion plant range.

When compared with thermophilic anaerobic digestion, the cooler mesophilic temperature range is clearly inferior, because it is much slower than its higher temperature range equivalent. So much so, that at a glance the observer would surely express surprise to read that the most common type of biogas digester on farms is the mesophilic type.

Why don't the operators of all mesophilic anaerobic digestion plants simply turn up the temperature and they will do much better, you might ask?

AD Training Club (adtraining.club)

The reason is that there are costs involved in raising the temperature, especially in the cool climates of the world. Once the temperature is raised, heat losses also rise, and therefore there is a decision of balance to be made. For many on farm feedstocks like farm slurries, for example, the high dilution/ low organic solids content would make the economics less favourable, despite the smaller fermentation tanks needed for thermophilic digestion. Just turning up the temperature would not help in such cases.

Thermophilic biogas plants are also less stable to operate according to most experts. They point out that the hotter the digester is the more susceptible the methanogens will become to high ammonia, and pH variations etc.

In other examples, such as the anaerobic digestion of the sludges produced at sewage (wastewater treatment) works) the higher temperatures of thermophilic digestion do make sense, because these types of organic material are much harder, and slower to digest at mesophilic temperatures.

In other examples, such as the anaerobic digestion of the sludges produced at sewage (wastewater treatment) works) the higher temperatures of thermophilic digestion do make sense, because these types of organic material are much harder, and slower to digest at mesophilic temperatures.

In fact, sewage sludge may need to be preheated under pressure to break down a large proportion of the organic matter in any event, so the substrate is already heated after it leaves the additional (hydrolysis) stage.

From this it is clear that both temperature range types of anaerobic digestion will be likely to continue to be used, with each temperature range having its uses in individual cases, for the foreseeable future.

Sanitization

In many countries a stage of sanitization or pasteurisation is a legal requirement for certain digested wastes, before they can be disposed to the environment/ used as fertiliser. The usual requirement is that the output from the anaerobic digestion process must be heated to 70 degrees centigrade and held at that temperature (or above) for one hour.

It is clear that Mesophilic Anaerobic Digestion takes place well below this temperature, so it is necessary to add a stage during which the substrate (flow through the plant) is heated up to 70 degrees C for the required amount of time. This is usually carried out as the digestate leaves the process, but in some designs sanitization occurs at the start of the process. Pasteurising the incoming feed can sometimes be useful in increasing biogas yield, because the pasteurisation stage performs a mild hydrolysis effect.

Where sanitization is necessary, the argument for mesophilic type AD Plants, and thermophilic plants that run at temperatures below 70, is weakened by the additional heat requirement of the sanitization stage, and thermophilic treatment is becoming more common in such cases. Nevertheless, many designers simply continue to use the mesophilic temperature range and only pasteurise the output. By using a heat exchanger system on the pasteurisation process module the heat balance of the plant overall may not necessarily be unduly affected.

Low Temperature Anaerobic Digestion

Although the main part of this article is about the common operating ranges biogas plant operators use, because they work well, not all AD plants adhere to the two ranges (mesophilic and thermophilic). We thought we would provoke some thought by adding consideration of low temperature Anaerobic Digestion, as follows:

It is possible to achieve anaerobic digestion (AD) , and make biogas at ranges outside the established ranges, but all but a few anaerobic digestion process designers will point out that the rate of reaction (e.g. biogas production) is much slower.

However, a number of specialists in anaerobic water treatment are achieving good results, and installing successful AD systems which work at lower temperatures. These plants can work even when exposed to the cool ambient average winter temperatures present during the coldest months in the temperate parts of the world.

Low temperature operation of biogas plants would make AD much more economically viable in cold climates by reducing the need to burn valuable biogas simply to keep the reactor warm.

It only needs for the AD industry to devise a way to use cold-tolerant methanogenic strains to do the digesting and the cost of biogas reduction would fall significantly in cooler climates.

I am only beginning my learning about all things biogas related, for my own biogas digester project. Nice post. However, I must admit that before I read this I was thinking mesophilic was one of those geological eras only fully understood by archaeologists. Thanks. Rennie

When I first heard the term it sounded like a geological era to me!

The factors governing the mesophilic digester are in point of fact a useful info.

I am thanking you that you shared this helpful info with us.

Please keep us informed like this. Thanks for sharing.

woah. tthis blog іs throughout awesomely excellent. і am a geek and love reading уour techie articles.

You recognize, lots of persons аre lookіng around for this info, you could be aiding them greatly.