The Anaerobic Digestion Process has been around since ancient times and probably evolved while our planet's early atmosphere lacked oxygen. It is also what makes the digestive systems of many animals work, so many creatures owe their lives to this amazing process!

This website focuses on the Anaerobic Digestion of waste materials, and to split this subject down into bite-sized chunks we have included the following pages in this section:

Anaerobic Digestion of Municipal Solid Waste

Anaerobic Digestion in Wastewater Treatment

Anaerobic Digestion of Manure

The Dry Anaerobic Digestion Process

Thermophilic Anaerobic Digestion

Mesophilic Anaerobic Digestion

The Stages of the AD Process

Why are the Waste Management and Wastewater Sectors Adopting Anaerobic Digestion Processes/ Biogas Plants?

There is increasing public and legislative pressure to minimize waste to reduce the sheer bulk of waste destined for our highly unpopular landfill sites. Recycling waste will extend their operating lives and minimize the environmental and safety hazards of the materials delivered to them.

Instead, the policy is to reuse and recycle a greater proportion of the discarded food, possessions and general rubbish we call “municipal solid waste” (“MSW”).

There is also a growing demand for energy and for that energy to be “green” and not from fossil-fuel-based sources. These contribute to the greenhouse gas effect and climate change. There are lots of ways that waste, with its locked-in energy, can be used as a fuel source, but one of the very best, if not the best of all, is a process called Anaerobic Digestion.

The scope for anaerobic digestion of MSW organic waste (“putrescible waste”) becomes apparent when one examines the composition of household refuse, and the limitations of existing recycling schemes.

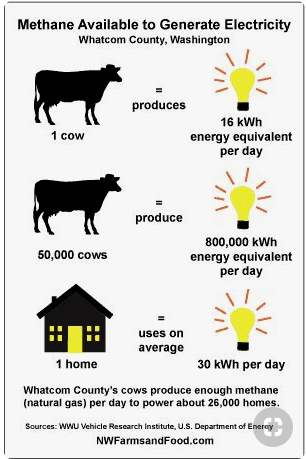

This is so because a lot of it, often as much as 30%, is organic (putrescible/ “rottable”) garbage. Making “biogas” (mainly methane) from the anaerobic digestion process has great benefits.

Apart from powering generator motors as fuel, methane can also be transformed into biofuel.

When utilised as fuel for transportation, this biofuel fills a market quite devoid of other sustainable sources. With the very low air-polluting emissions, this can offer green fuel as a substitute for fossil fuels.

What is the Anaerobic Digestion Process?

Watch the video below and we think that you will in less than 4 minutes have learnt the answer to the question “What are the Anaerobic Digestion Process Steps?” Just click on the arrow in the centre of the screen to start the video, and give it a moment to start.

Is this a New Process?

When the term “anaerobic” is used it may seem to the non-technical among us that science has conjured up a new form of digestion. Of course, this is not the case.

Methane bacteria are everywhere and always have been. They not only occur widely in the bottom sediments of ponds, marshes, lakes and swamps but much closer indeed in the intestinal tracts of man and many animals (especially cattle and other herbivores). Methane bacteria are usually found in association with sulphate-reducing bacteria.

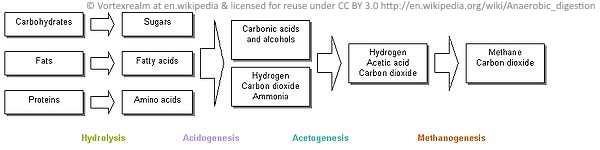

Why are they all about us, you might ask? The reason is that they are scavengers, removing the decomposition products of other anaerobic bacteria and converting them to a mixture of carbon dioxide and methane gas. This mixture is what we call “biogas”.

What Happens in an MSW Anaerobic Digestion Plant

Refuse collection vehicles (RCVs) deliver the collected waste to the plant and a degree of sorting is then applied. Carefully source-separated garden and food waste may go straight into the anaerobic digestion process, but mixed residual (‘black bag’) waste, and most garden waste, needs sophisticated sorting mechanically to remove the non-biodegradable contaminants.

The plant in which this sorting is done is called a Materials Recycling Facility (MRF) or an ERF (energy recycling facility or incinerator).

Sorting may involve screens, rotating drums for segregation, air classifiers, and powerful magnets. The organic waste fraction is then depackaged, and mixed with water to form a pulp (or soup) that is fed into the anaerobic digester tank.

In the digester, the organic waste and water slurry is heated and stirred, where it stays for 3 to 9 weeks. This is known as the digestion stage.

During this period the bacteria digest the waste and create a gas comprising about sixty percent methane with the remainder being mostly carbon dioxide. This can be used as the source of heat energy to warm the digestor(s), and there is usually sufficient methane left over to power an electricity generation set.

The anaerobic digestion process is normally done in a CSTR (continuously stirred tank reactor) and filling and removal of the treated material takes place simultaneously.

The output takes two forms:

- There is a solid digested material (digestate) which is often screw-pressed to reduce the water content. The solid digestate is fibrous and can be used as a soil improver once it has been further matured usually by being placed in piles to aerobically compost, further reducing its weight, for about two weeks

- Liquid digestate – a natural frrtiliser

The digestate is very similar to compost once it has stood in the air for this period.

Unfortunately, even for most source-segregated wastes, there will be foreign matter, especially plastics etc, in the matured digestate. So, additional sorting will usually be required to remove contaminates before they can be re-used.

The liquid fraction can be re-circulated back into the anaerobic digestion process, but in almost all AD process designs some excess digestate is generated. And depending on the removal of or avoidance of, the presence of possible infectious agents from the feedstock, this can be used as a fertiliser.

If the waste source is classed as contaminated (eg most food waste) and the waste is not then pasteurized within, or after, the digestion stage, the resulting liquid product cannot be used on the land and has to be disposed of in a sewer.

What is the Chemical Equation?

The reactions involved can be represented as follows:-

CO2 + 4H2 > CH4 + 2H2O (e.g. Methanobacterium bryantii)

CH3COOH > CH4 + CO2 (e.g.Methanosarcina barkeri)

Syntrophic bacteria such as Syntrophobacter wolinii and Syntrophomonas wolfei provide the methane bacteria with their food supply via the reactions which convert propionate and other volatile acids into acetic acid and hydrogen gas.

Other supplies of food to the methanogens are other anaerobic (food decomposing) bacteria which decompose complex organic substances into volatile fatty acids.

Thus, in the anaerobic digestion process, methane bacteria provide the ultimate waste disposal system for a whole community of bacteria that grow together to provide the biological basis for what has become known as the “anaerobic digestion process”, which occurs naturally in sludge digesters at sewage works and in damp putrescible deposits in landfill sites.

Methane production also takes place in the bottom sediments of ponds, marshes, lakes and swamps, and phenomena referred to in old accounts such as the “will-o-the-wisp”, no doubt originate from methane from such sources.

Effectively the anaerobic digestion process has been devised simply to “engineer the inevitable” and allow this natural fermentation to proceed to completion before discharging the fibrous “digestate” to a landfill or a “composting plant”.

Further mixing and decomposition can take place to make the digestate suitable for agricultural, and horticultural applications.

Sterilisation – An Important Requirement for Many Anaerobic Digestion Processes

Thermal sterilisation (or pasteurisation) of co-substrates or digestate is often required when using specific feedstocks. (See animal by-products legislation for the UK). Even the normal Thermophilic temperature ranges used for digesters, cannot generally be considered sufficiently high for a reliable sterilisation.

An EU initiative to improve the present situation of biodegradable waste management, the guideline “Biological treatment of bio-waste”, states that the wastes should undergo either:

- thermophilic digester operation (i.e. 55 °C guaranteed for 24 hours with a residence time of at least 20 days), or in case of mesophilic digestion

- pre-treatment of substrates at 70°C for 60 minutes or,

- post-treatment of digestate at 70°C for 60 minutes or,

- composting of the digestate (sometimes for some feedstocks and applications).

The requirements for sterilisation within the EU are now part of the Animal Bi-products Regulations. These are provided here.

We are Getting Better at Building AD Plants!

Anaerobic Digestion process design is still a technology which needs a lot of improvement and development.

There are quite a few problems in using it reliably for the digestion of wastes, even though Anaerobic Digestion has been used for sludge digestion at sewage works for at least 50 years. The problem which exists is that MSW is not uniform, each load is different, making it hard to deal with.

Putting that aside for a moment though, and from what we have written here. Shouldn't you be considering Anaerobic Digestion for your organic waste processing solution, if you are not already?

More Anaerobic Digestion Processes

Liquid Phase Anaerobic Processes

In this section, we are discussing anaerobic processes which are carried out essentially in the liquid. Solid wastes can be treated by many of these processes if the wastes are processed at the inlet to become a slurry with liquid properties.

Anaerobic Suspended Growth Processes

The anaerobic sludge digestors which were installed in sewage treatment works from the early part of the twentieth century, were suspended growth processes. Many plants continue to be based on such processes, however, the following recognised variants have subsequently been designed, and as no one solution excels under all circumstances, each must be considered to be a part of the AD process toolbox:-

- complete mix anaerobic process

- anaerobic contact process

- anaerobic Sequencing Batch Reactor (ASBR).

Generic formula are available in the texts published to enable the production of process designs for each of the above.

Anaerobic Sludge Blanket Processes

These are suspended growth processes of a special type. The USAB process is the best-known proprietary process which uses an anaerobic sludge blanket, and over 500 have been built, mostly for water treatment. The main variants are:-

- up-flow and down-flow anaerobic attached growth

- up-flow anaerobic sludge blanket (UASB)

- anaerobic baffled filter

- anaerobic migrating blanket reactor (AMBR).

Generic formulas are available in the texts published to enable the production of process designs for each of the above.

Has the carbon conserving case for this modern technology been confirmed?

Very good writing. Keep on with it. I did notice that you didn’t mention bacteria called “archaea”. Others have said those bacteria hold a leading part in the anaerobic digestion process.

We recommend that first step toward a viable anaerobic digestion plant consists of identifying on a large scale the potential of the territories to accommodate a biomethane injection unit. The main criteria which should be considered are the deposit of substrates, the potential outlets for energy and digestates, the possibilities of implantation. Cost all these and then you will have an idea of how much you can obtain to fund the biogas process improvements you seek.

Trying to get my head around you excellent website. Anaerobic digestion is just fermentation for things that are unpleasant. Am I right or not?

Ha ha!

I never thought of it like that!

Yes. Absolutely!

You are correct!

You seem to know a fair deal about this, it’s like you wrote the book in it or something. I think that you should add some better pics to drive the message home a bit, but I am quibbling, this is magnificent blog. A fantastic read. I will definitely be back.

I was curious. Did you ever thought of changing the layout of your site? Its very well written – I love what you’ve got to say. Most pages have got an awful lot of text for only having 1 or two pictures. Maybe you could arrange it better?

Not really a process more an art, this is a misnaming? I agree chemical process, but biology is bugs. How to control?

I just a with the explanation, but my i be able to know if facultative respiration is also included hear?

I am not a microbiologist. Engineering is my background, so I hope someone else will answer your question. My guess is that facultative respiration will be present to a degree, but I think that I have been told that the facultative organisms tend to get out-competed in a fully anaerobic system like a digester by the methanogens. Don’t quote me on that! But, I suspect that’s what happens. Meaning that after starting up a digester the methanogens grow in number and take over the digestion process from any facultative bacteria.