With the massive public concern about plastics entering the environment today's news of a new digestate separator device that successfully removes plastic packaging waste, is very good news. It removes bits of food waste packaging, and other unwanted materials from entering the digester, and from the slurry which pours out of all wet-process biogas plants as a solid/ liquid “mush”.

The global challenge of achieving net-zero by 2050 just got a little easier!

It's very good news for the environment and also for:

- the humic material most depleted global agricultural soils badly need for replenishing their crop output

- renewable non-mineral/ non-mined fertiliser supplies for healthy and high crop yielding agricultural output,

which the digested remainder after biogas production can easily provide in large quantities.

The Big Picture About Digestate Separator Success!

The large scale use of the anaerobic digestion process is relatively recent, and the technology advances almost daily, and that's because it is a young technology – only revived in the last 20, or so, years.

In any young technology, there is always likely to be better ways of doing things when clever people find them! So it seems to have proved here with this digestate separator!

At last, the market for biogas plants has reached the size when innovative engineers at companies like Borger can do the research and development and spend the time and money to create advances of this sort.

Until now, it has been hard for businesses to justify funding the development of new equipment to deliver literally life-changing significance for wild animals and the world's oceans.

Until now, and with the development of this separator technology, food waste derived compost has tended to contain so many flecks and chips of plastic that it has not only posed a danger to wildlife, it also looked bad!

Plastic bits and pieces in the fibrous compost from food waste digesters meant that in the past it was often no good at all. It really did not even look good enough for most people to consider it usable.

Nevertheless, once this output is found by regulatory authorities to be acceptable to be used in agriculture, food waste digester operators will be released from the high financial burden for disposing of these materials as waste.

So, that is our outlook on the importance of the digestate separator described in today's Borger Press Release published below:

Plastic “Out” with New Separators at Food Waste/Biogas Plant

Following an extensive trial at one of the largest waste processing plants in Europe, separators made by Borger are now playing a crucial role in improving the quality of the digestate used for land fertilisation in accordance with PAS 110 regulations.

The facility, which generates up to 5.9 MW of electricity from over 100,000 tonnes of food waste per year, had been looking to progress the way it removes contaminants such as plastic from the final digestate.

Previously, the plant was using centrifuges to create a solid digestate but felt that it could further improve the quality of its final product by producing a liquid digestate.

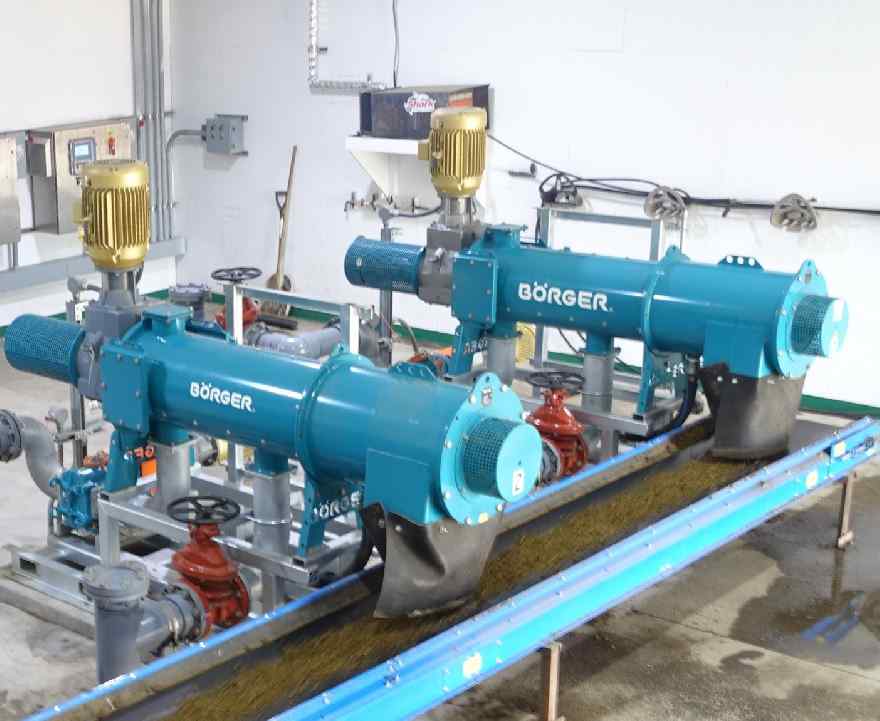

RC 75 Separators from Borger were introduced, to see how they could deal with the significant challenges of hard-to-handle materials that come with food waste.

For a full 12 months, the Separators were put through their paces; monitored for their whole life performance and durability in an application that makes tough demands on wearing parts.

Designed with a leakproof rotating multi-disc, the energy-efficient 75 m³/h Borger Separators benefit from having no metal-to-metal parts, with no abrasion between the auger and the wedge wire screen – and separation of the dewatering box and press channel to protect material.

“Our customer certainly found these new separators very suitable for the tough application”,

said David Brown, Managing Director of Borger UK.

“They have enhanced the way that they filter out contaminants, separating solids 24/7 very effectively, which provides excellent peace of mind because it reduces the risk and the significant cost of any final product being sent to landfill”.

‘More capacity in the digesters’.

He continued:

“By improving the quality of the digestate, we have also helped the food waste/biogas facility reduce the cost and time of their chemical usage. For such sturdy pieces of equipment, the separators are simple to operate and maintain. The hiring unit was a stand-alone, but the two separators are now fully integrated into the process. Another benefit is that with their capability in removing more solids, the separators provide more capacity in the digesters”.

Conveying the feedstock from the digester to the separators are self-priming Borger PL 400 rotary lobe pumps, which despite having had to fit into a confined space, have also proved very easy to maintain.

‘Pumps only need simple tools to service’

A spokesperson for the food waste/biogas facility added:

“The Borger pumps are very reliable and so much easier to strip down and rebuild than other pumps – some of which we know are going to be a very time-consuming job on the bench, whereas with Borger, we only need simple tools to carry out maintenance in place”.

He added:

“These PL 400 pumps can, if necessary, be taken apart and put back together in just a couple of hours – and there’s never an issue getting parts. Borger are a very good and easy company to work with. They know what they’re talking about”.

Borger UK

01902 798 977

www.boerger.com

uk@boerger.com

Press Release published 18 June 2021 – Ends