Turning waste into energy is a big challenge. Yet, the process of thermophilic anaerobic digestion offers a powerful solution and is seldom used, with most AD plants being mesophilic (lower temperature) digesters. The high-temperature range method uses the high heat to break down organic matter without oxygen more rapidly, creating more biogas daily per unit volume of a digester tank.

Biogas has the big advantage of being both sustainable and clean energy. Most people don't know that this process works faster at temperatures above 50°C.

Biogas has the big advantage of being both sustainable and clean energy. Most people don't know that this process works faster at temperatures above 50°C.

I have spent years studying how tiny living things break down waste in hot conditions to make gas or fuel. My studies have convinced me that getting the right mix of heat and microbes can greatly increase biogas production.

Waste such as food leftovers and the remains of crop-grown plants are key ingredients for this green power-making process.

Ready to learn how you can turn waste into energy efficiently? Let's explore thermophilic anaerobic digestion together.

Key Takeaways

- Thermophilic anaerobic digestion happens at high temperatures, between 50°C to 65°C. This method is great for making biogas because it breaks down organic waste relatively quickly and kills harmful germs (pasteurises).

- Lignocellulosic biomass, like wood chips and straw, is a key feedstock for producing biogas in this process. Special microbes work together at these high temperatures to turn plant materials into useful energy.

- Using a thermophilic inoculum can be useful when starting up a new digester as it boosts biogas production by speeding up the growth of an adequate mass of these heat-loving organisms for the breakdown of organic matter. It uses heat-loving microbes that outperform those in cooler processes.

- The performance of thermophilic anaerobic digestion depends on getting the right temperature and pH levels, the balance of nutrients, and using the right types of waste material.

- To make this process even better, pre-treatment methods can help break down tough cell-walled substances before digestion. Managing the FOS/TAK quality of the digester substrate to foster microbial communities carefully also helps improve efficiency and gas output.

What is Thermophilic Anaerobic Digestion?

Thermophilic anaerobic digestion works at higher temperatures. It enhances biogas production and speeds up the process.

Definition and temperature range

Thermophilic anaerobic digestion (TAD) is a process that breaks down waste without oxygen and at high temperatures. This method works best between 50 to 65 degrees Celsius. At these temperatures, special heat-loving bacteria thrive.

They play a key role in turning organic waste into biogas.

This range, above 50 degrees Celsius, suits the bacteria perfectly, letting them work fast and efficiently. It's ideal for managing sewage sludge and other types of organic matter in biodigesters.

The heat not only speeds up decomposition but also helps kill harmful germs, making the process safer and more effective for treating wastes before they're released or reused.

Benefits of operating at higher temperatures

Operating at higher temperatures speeds up biochemical reactions. This means organic materials break down faster in thermophilic anaerobic digestion, leading to quicker methane gas production.

Such conditions make the anaerobic digesters work more efficiently, offering an improved breakdown of tough organic matter compared to cooler processes.

High-temperature anaerobic digestion also kills more harmful germs, although there is no certainty that the digestate will pass the temperature and duration requirements of the UK Animal By-products Regulations.

By reaching these elevated temperatures, the process ensures a safer end product for use or disposal. This makes it a better choice for managing waste and producing energy in biogas plants, providing both environmental benefits and meeting safety standards for bioenergy production.

However, against this higher speed benefit is the inevitable disadvantage that if things do go wrong, the digester output will become less stable sooner than for the equivalent lower temperature (mesophilic) digester.

Lignocellulosic Biomass: A Key Player in TAD

Lignocellulosic biomass, which is made up of cellulose, hemicellulose, and lignin from plant cell walls, is an important part of thermophilic anaerobic digestion (TAD) for making biogas.

Utilising this abundant and renewable resource optimises the overall efficiency of TAD systems.

Explanation of LCB and its importance

Lignocellulosic biomass (LCB) comes from plants and is full of polysaccharides like cellulose and hemicellulose. This material serves as an important food source for anaerobic digestion, a process that turns complex organic matter into biogas.

Because it's abundant and renewable, LCB plays a key role in producing clean bio-energy efficiently and cost-effectively.

Using LCB means we can turn plant-based materials into valuable biogas without using fossil fuels. This method not only supports the use of renewable resources but also helps manage waste more effectively.

Now, let’s see how this biomass gets converted into biogas through thermophilic anaerobic digestion.

How LCB is used in TAD to produce biogas

Understanding the role of lignocellulosic biomass (LCB) sets the stage for exploring its use in thermophilic anaerobic digestion (TAD) to create biogas. In this process, LCB, consisting of plant materials like wood chips and straw, becomes a vital feedstock.

Microorganisms break down these tough plant parts best at high temperatures within TAD systems. This breakdown is crucial for producing biomethane, a type of biogas.

The high-heat environment of TAD makes it ideal for decomposing LCB faster than at lower temperatures. Special bacteria and other tiny life forms thrive in these conditions. They work together to convert LCB into methane and carbon dioxide through stages such as hydrolysis and acidogenesis.

The final step involves methanogenic archaea turning acids into biomethane gas which can be used as renewable energy or fuel.

The Impact of Thermophilic Inoculum on AD

Using thermophilic inoculum can significantly improve biogas production in anaerobic digestion due to its ability to enhance microbial activity and accelerate the degradation of organic matter.

This leads to a more efficient breakdown of complex substrates, ultimately increasing methane yields and optimising the entire process.

Definition of inoculum and its role in TAD

Inoculum kickstarts the breakdown of organic waste in thermophilic anaerobic digestion (TAD). It's a mix of microorganisms, including bacteria and archaea, which are crucial for carbon dioxide, a clean energy source.

The right type and quality of these microbes can speed up this process and boost biogas production.

Thermophilic inoculum works at high temperatures between 50°C to 70°C. This helps break down tough materials faster than cooler mesophilic processes.

These tiny workers make renewable energy generation quicker and more effective.

How using a thermophilic inoculum can enhance biogas production

Using a thermophilic inoculum speeds up the breakdown of organic waste. This quick process leads to more biogas in less time. The heat-loving microbes in the inoculum work faster at high temperatures, breaking down tough materials that slower microbes can't handle.

This means we get more gas from the same amount of waste.

These powerful microbes also make anaerobic digestion more efficient. They turn hard-to-digest bits like lignocellulosic biomass into methane and carbon dioxide quickly. With these helpers, treatment plants see higher biogas yields and better degradation rates.

This method is a step ahead of cooler processes, making it a smart choice for managing organic waste and producing energy.

Factors Affecting TAD Performance

Various factors influence the performance of Thermophilic Anaerobic Digestion (TAD). These include temperature and pH levels, nutrient balance, and types of feedstock. Success in TAD relies on understanding and optimising these critical aspects.

Temperature and pH levels

Temperature and pH levels play big roles in making biogas through thermophilic anaerobic digestion. The best temperature for creating more biogas is key. Hotter conditions help microorganisms break down organic matter faster, leading to more biogas.

But, if it gets too hot or not hot enough, the process slows down.

The acidity or alkalinity of the environment, known as pH, also matters a lot. Microorganisms need the right pH to work well. If the digester becomes too acidic or too alkaline, these tiny workers can't do their job properly, affecting gas output.

Keeping an eye on these factors ensures everything runs smoothly for top-notch biogas production.

Nutrient balance

Maintaining the right balance of nutrients is crucial for optimal biogas production. Imbalances can hamper the process, leading to reduced biogas output. Proper management of nutrient levels is essential for maximising anaerobic digestion performance and ensuring efficient biogas generation from waste materials.

Ensuring a balanced mix of nutrients such as nitrogen, phosphorus, and trace elements is vital in maintaining high biogas production levels. Any imbalance in these nutrients can disrupt the process, leading to decreased efficiency and lower gas yields.

Therefore, careful monitoring and adjustment of nutrient levels are necessary to sustain an effective anaerobic digestion system.

Types of feedstock

Various types of feedstock, including food waste and lignocellulosic wastes, are utilised in thermophilic anaerobic digestion for biogas production. Additionally, wheat straw has been extensively studied for its potential in producing biogas through thermophilic anaerobic digestion.

Strategies to Optimise TAD Efficiency

To optimise TAD efficiency, pre-treatment methods can be utilised. Microbial communities should be carefully managed to enhance performance.

Utilising pre-treatment methods

Pre-treatment methods improve organic matter breakdown and reduce the need for extra treatment. They help to disintegrate substances inside and outside the cells, making degradation easier.

Adding conductive materials can boost methane production in thermophilic anaerobic digestion (TAD) and counteract process disruptions. Appropriate pre-treatment strategies enhance both extracellular and intracellular substance decomposition, increasing efficiency and reducing costs.

Selection and management of microbial communities

To optimise thermophilic anaerobic digestion (TAD), careful selection and management of microbial communities are crucial. The composition of these communities, impacted by temperature, feedstock type, and seed inoculum, directly influences TAD efficiency.

Microbial diversity within the digester drives organic matter degradation and biogas production.

Establishing and maintaining a balanced microbial ecosystem is key to sustainable waste management practices. Factors such as conductive materials can enhance TAD performance by promoting direct interspecies electron transfer among microbial communities.

Monitoring and control techniques

To maintain optimal performance in thermophilic anaerobic digestion (TAD), it is crucial to employ effective monitoring and control techniques. Regular assessment of temperature, pH levels, and FOS/TAK nutrient balance ensures stable conditions for the microbial community.

Adjustments can be made based on real-time data from gas chromatographs to maximise biogas production.

In addition, implementing hydraulic retention time control and continuous monitoring of methanogenesis activity is essential for avoiding process upsets and optimising TAD efficiency.

Advantages of Thermophilic Anaerobic Digestion from our experience

The advocates of thermophilic digestion (or thermophilic biodigestion) give the main advantages over the more common mesophilic anaerobic digestion temperature range, such as better sludge quality and higher biogas production.

In our experience, those benefits vary according to the type of material that is digested.

Comparing TAD for sewage sludge with TAD for household and commercial food waste

Municipal Solid Waste lyses (breaks down within the cells) relatively easily when compared with, for example, sewage sludge. So, thermophilic anaerobic digestion may become popular for sewage sludge because it is so slow to digest at mesophilic temperatures. But, it is not likely that the same applies to municipal solid waste (MSW) such as food waste. The additional sacrificial heat burden of heating the reactor for readily digestible food waste in a cool climate would not be likely to be worthwhile.

Accelerating the hydrolysis stage

The hydrolysis stage of the AD process is widely regarded as a rate-limiting step in sludge digestion, thus, improvements in hydrolysis rates which occur naturally at higher temperatures have the potential for significant improvements in overall apparent sludge digestion rates.

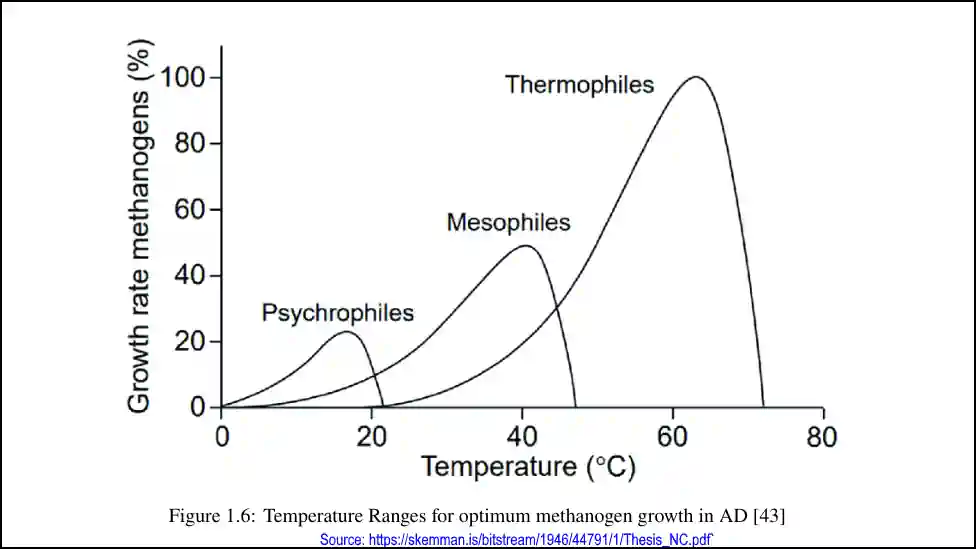

Therefore, many “optimized” thermophilic reactors operate right at the top of the thermophilic temperature range. At this point, the naturally occurring methanogenic bacteria begin to become less efficient, so any further increase in temperature tends to reduce efficiency and not raise it.

Incidental benefits of TAD

Some researchers have reported that they have been able to reduce the hydraulic retention time (HRT) from a necessary 15 to 20 days in mesophilic digestion down to as little as 3 days at a thermophilic temperature in the region of (55°C) with stable fermentation and methanogenic activity.

That is an illustration of just how much of an effect the temperature of an AD plant reactor can have

Improvements in the rate of the AD process, at thermophilic temperatures, have beneficial knock-on effects, as they also:

- reduce mixing energy requirements by reducing substrate viscosity,

- reduce wear-and-tear on mixing equipment, and

- reduce overall heat loss per unit volume of material processed, reducing costs.

Disadvantages of TAD

But, more energy is consumed to raise the temperature initially, and for high rates of throughput in cool climates, this can be very significant.

Also, when a reactor is initially commissioned from cold on a new site, the entire reactor must be heated to a higher thermophilic temperature range, largely using “bought-in power,” normally from the local electricity provider.

This adds to the initial investment needed to start up a new biogas plant installation.

The robustness of the process is good, for most mesophilic digesters. Thermophilic digesters tend to go wrong more rapidly. Reliance on the lowest possible hydraulic retention time is a cost-saving strategy for any AD facility developer. But to “go thermophilic,” the operator needs to be very confident in their ability to keep the system stable.

The reason for this is that there can be so little time to react if a thermophilic reactor starts to experience problems.

Loss of reactor up-time during the time needed for high-rate reactors to be “teased back” into full biogas production, can be very costly. So we caution that all decisions on optimizing throughput need to balance the economy of initial capital expenditure in smaller-reactor sized thermophilic AD plants with the robustness of plant operation throughout its life.

Conclusions and Future Perspectives

In summary, thermophilic anaerobic digestion harnesses high temperatures to produce biogas from organic waste. Optimising this process involves using thermophilic microorganisms and carefully managing temperature, pH levels, FOS/TAC and substrate composition.

These practical strategies are easy to implement and can lead to significant improvements in biogas production efficiency. By applying these approaches, the environmental impact of waste management can be reduced while also producing renewable energy.

Further research on the microbiome of biogas plants and exploring additional organic materials for digestion could unlock even more potential in this field.

[/soc_panel]

FAQs

1. What is thermophilic anaerobic digestion?

2. How does it differ from conventional wastewater treatment?

3. Can this process help fight climate change?

4. What are some key benefits of using thermophilic anaerobic digestion in sludge treatment?

5. Why is microbial activity important in this process?

6. Are there any advanced technologies involved in optimising this digestion process?

7. What is Thermophilic Anaerobic Digestion?

According to Wikipedia:

“A thermophilic digester or thermophilic biodigester is a kind of biodigester that operates in temperatures above 50 °C producing biogas. … In fact, it can be as much as six to ten times faster than a normal biodigester.”

[/soc_panel

Visit our advanced bio-thermic digestion article here.

Source URLs:

https://www.researchgate.net/publication/41423165_Thermophilic_anaerobic_digestion_The_best_option_for_waste_treatment

https://www.sciencedirect.com/science/article/abs/pii/S2589014X23000737

https://www.mdpi.com/2073-4441/15/14/2653

https://www.researchgate.net/publication/367723656_Biogas_Production_Performance_and_System_Stability_Monitoring_of_Thermophilic_High-Solid_Anaerobic_Co-Digestion_with_Lipids_and_Food_Waste

https://doi.org/10.1016/j.psep.2024.03.123

https://jp.hach.com/asset-get.download.jsa?id=58615148853

Why do you need to heat the digestate still hotter than in a thermophilic digester? This is already hot and is hot for a long period. I read that the liquor stays in a thermophilic biogas digester for say 10 to 20 days. This is hot enough? No?

Welcome to a first in biogas plants. Thermophilic is your hot choice. Also, Meso. Do your own assembly of complete biogas plant. Medium and large size PUXIN Portable Assembly Biogas System is a Do It Yourself (DIY) BIOGAS SYSTEM for convenient transport and easy assembly.

You are welcome to visit our company. Our company is located in Shenzhen the city that is just beside Hong Kong. If you come, the best way is to flight to Shenzhen airport directly. You should tell us your flight details ahead by email that we can send a driver pick you up at Shenzhen airport upon your arrival. You can also fly to Hong Kong and take a bus from Hong Kong international air port to our company.

Many people think that it’s extremely hard to promote Thermophilic Anaerobic Digestion in the UK. Even so, many of the signs and symptoms can indeed be improved to the level that their impcts are virtually negligible. So long as you be cautious about signs of worsening symptoms, these pointers will be able to allow you to ease your most detrimental signs or symptoms. Astonish your mates with your pictures, and videos, utilising the photography ideas.

Is pasteurisation really needed for thermophilic systems? Surely it is held at a very hot temperatures for so long – pasteurisation should not be necessary?

My question is what’s so hard about thermophilic digesters? Why isn’t everyone going thermophilic?

Good info. But, you fail to mention anywhere about Psychrophilic biogas production in the temperature range around 20 degrees Centigrade (68 degrees Fahrenheit). It isn’t as rapid but it can still work, especially for large volumes of lower level organics present.

Natalie – Yes. You are right. This article was written in 2014, and I guess that things have moved on since then. I’ll do an article on psychrophilic biogas production as soon as I can find time.

With appropriate bacterium consortium and heating only at upper and central part, that have 3-4 days equivalent amount of feed . It is possible. If it is possible for me ,why others can’t do?

Question to the author: which companies currently offer best thermophilic AD for energy plants such as maize, grass etc? Thanks

Rusli. Hi! That’s an interesting question but I’m afraid there is no answer I can give you “off the cuff”. There are so many factors involved, not least the geographic factor of where this biogas plant would be located.