An alternative title to the classification of pumps would be the “types of water pumps and their working principles”. Pumps are divided into 2 major categories: Dynamic and Positive Displacement (actually you might as well just call them Displacement) pumps. Centrifugal pumps are the most common pump type used globally, that's because of their simple working principle. And, for this high volume of production and “simple” pump type, you can also read “relatively low” manufacturing and total ownership cost.

Many engineers start out their pump selection by looking for a centrifugal pump which will perform the duty. It is only after finding that there are characteristics of their pump application which make a centrifugal pump unsuitable that they go on to consider other choices.

To a large degree the success of all water projects depends on the selection of reliable pumps, so this article is relevant to all those selecting pumps The Classification of Pumps is important not only to anaerobic digestion and biogas plant designers, but to all those involved in pumping liquids and mixtures of materials.

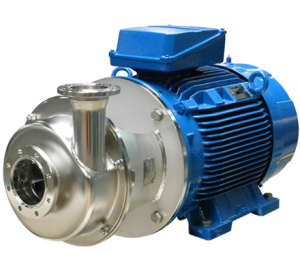

Pump Classification 1 – Centrifugal Pumps (aka Roto-dynamic pumps)

The centrifugal (also known as a roto-dynamic) pump produces a head and a flow by using a rotating vane impeller. Think of something like a ships propeller which is surrounded in a circular case, where the rotation flings the water outward from the centre! The force imposed by the rotation of the impeller forces the liquid which starts at the centre, out to the edge which induces a pressure and a flow results. You know this is you've ever spun a ball on a string. We've all done that! You know the feeling of the tug outward on your hand and arm!

Centrifugal pumps are best for pumping large volumes of water long distances, both for clean water supply and for sewage, and drainage uses.

Centrifugal pumps have been developed for a wide range of uses, and when classed by their internal flow characteristics include; axial, radial, and mixed-flow units. Each has its own particular merit when used in specific applications.

Centrifugal pumps can be classified further by their special features, again to optimise their efficiency for specific uses:

- submersible pumps (for clean water, for sewage and high-solids passing)

- self-priming pumps and manual priming

- regenerative pumps

- end-suction pumps

- in-line pumps (booster pumps)

- double-suction pumps

- vertical multi-stage pumps

- horizontal multi-stage pumps

- rotating shaft driven

- air-driven

- hydraulically driven

- variable speed – although that's usually a feature of the control system (electrical inverter) provided rather than the pump itself.

The classification of pumps regarding centrifugal pumps, can often be spilt down further into the materials used for the casing (elute) and the impeller such as ductile-iron, cast-iron, stainless steel etc.

Finally, we must mention that many centrifugal pump manufacturers also offer different material types for the all-important water seals around the rotating shaft. These seals must be very physically and chemically hard-wearing to stop water getting into the motor around the spinning shaft (rotor).

The choice of materials for the main pump components and the seals, will depend upon the corrosive, and “gritty” abrasive wearing nature of the water pumped. The cleaner the water generally, the cheaper the materials which can be used.

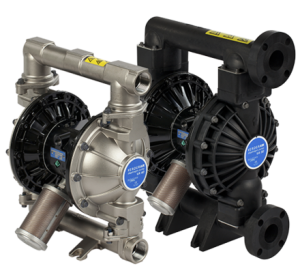

Pump Classification 2 – Positive Displacement Pumps

A positive displacement pump operates by alternating filling a cavity and then displacing a given volume of liquid. A positive displacement pump delivers a constant volume of liquid for each cycle, independent of discharge pressure or head.

A positive displacement pump operates by alternating filling a cavity and then displacing a given volume of liquid. A positive displacement pump delivers a constant volume of liquid for each cycle, independent of discharge pressure or head.

Positive displacement pumps are most suitable where an accurate quantity of water must be supplied, and where the pressure at which the pump must deliver the flow will vary over time, according to conditions elsewhere in the system. In such conditions a centrifugal pump would deliver a varying flow.

The flow a positive displacement pump provides is simply a function of the number of displacements and the volume of each displacement. Think of a piston, where the flow is delivered every cycle and the volume each time, is proportional to the length of each stroke.

In general positive displacement pumps provide a pulsed flow.

Where centrifugal pumps are mostly used to pump just water albeit that this can include small solids as in sewage. Positive displacement pumps excel at pumping not only water, but chemicals, and mixtures of solid and fibrous materials (including viscous muds, silts and slurries, food, and pastes, abattoir waste etc) which would often block, or rapidly wear-out a centrifugal pump.

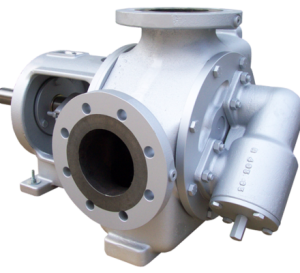

Positive displacement pumps, like centrifugal pumps come in all sizes, but are made in an even wider range of materials. The more detailed classification of pumps of this type, can be listed as:

- Reciprocating pumps – piston, plunger and diaphragm

- Electric powered pumps

- Steam pumps – Think of the industrial revolution, and tin mines!

- Rotary pumps – gear, lobe, screw, vane, regenerative (peripheral) and progressive cavity

- Diaphragm pumps

- Peristaltic pumps.

When to Choose Centrifugal or Positive Displacement Pump Types

Making the all-important choice between a Centrifugal Pump or a Positive Displacement Pump is not always straightforward.

It is best tackled by considering flow rate and pressure head requirements, the viscosity (stiffness), corrosive and abrasive characteristics of the liquid being pumped, and finally mechanical efficiency.

We have called each of these our “choice factors”, and split these 3 ways for our classification of pumps, as follows:

Choice Factor 1: Flow Rate and Pressure Head

The classification of pumps within these two categories, behave very differently regarding pressure head and flow rate:

- The flow from any Centrifugal Pump varies depending on the system pressure or “head”

- The flow from a Positive Displacement Pump is a constant flow (within known limits), regardless of the system pressure (head).

- Positive Displacement pumps are generally more flexible on the range of flows, and pressures any one pump can be adjusted to deliver. Whereas, individual Centrifugal Pumps, once in-place, are more limited in the range of heads and flows they can deliver. This is both inherent in the nature of a centrifugal force, and also due to a phenomenon know as “cavitation”. Cavitation can occur when a centrifugal pump is run at above its design limits, or the pipe flow characteristics were wrongly specified. It can cause lower pump efficiency and accelerated impeller wear.

- Positive Displacement pumps are not so good at high volumes of flow, when they can become unmanageable (large and bulky).

- Progressive cavity type positive displacement pumps can fail on blockage by rotor shear and breakage, whereas centrifugal pumps generally fail more gradually from a progressive loss of efficiency as they become worn.

Choice Factor 2: Capacity and Viscosity

Another major difference between the centrifugal and displacement pump types is the effect of viscosity on capacity:

- In a Centrifugal Pump the flow is reduced when the viscosity is increased.

- In a Positive Displacement Pump the flow is unaffected by the viscosity. The exception is for progressive cavity pumps.

Progressive cavity pumps cannot be built to a perfect fit between the spiral impeller and the casing. This means that flow-back in the gap between the impeller may be lower when pumping high viscosity materials. As a result, the flow may actually be increased when the viscosity is raised. To imagine how this works, think of an Archimedes spiral type of pump, pumping concrete where the spiral rotates within a radial floored concrete trough…

To put it another way: Positive Displacement Pumps are better suited for higher viscosity applications. A Centrifugal Pump becomes very inefficient at even modest viscosity, because it needs to fling the material outward rapidly and viscous materials require a high shearing energy before they will do this.

Choice Factor 3: Mechanical Efficiency

The two pump types behave very differently when considering mechanical efficiency as well.

- Changing the system pressure or head outside the range which a particular impeller shape is designed to work within, will have a dramatic effect on the flow rate for a Centrifugal Pump

- Changing the system pressure or head has minimal, or no effect on the flow rate in a Positive Displacement Pump. However, the motor must be chosen to be able to deliver the amount of power needed, and the working pressure range is finite, although much wider than for Centrifugal pumps.

Net Positive Suction Head – NPSH

Within the classification of pumps, another consideration is the Net Positive Suction Head – NPSH.

- In a Centrifugal Pump, NPSH varies as a function of flow determined by pressure

- In a Positive Displacement Pump, NPSH varies as a function of flow determined by speed. Reducing the speed (cycles/minute) of the Positive Displacement Pump pump, reduces the NPSH.

Classification of Pumps: Conclusion

We hope that this article has helped you to understand the classification of pumps into two main types of water pumps, centrifugal and displacement. If it has served to open your mind to the choice of pump types available, and the relative merits of each classification of pump we will consider our job done!.

Note: All images are courtesy our sponsor Verder. Verder are recognised as providing premium industry brands, and the range of different pump types they offer is one of the largest in the industry. Certainly, Verder offers the most comprehensive range of all pump types that we have seen. Contacting Verder for assistance with the selection of a suitable pump for any application, means that buyers can generally be confident that they have covered all the tried-and-tested possibilities, and the pump selected will be the most optimum available.

Thank you for sharing this. Also i am having trouble to choose the right pump. I read that, should there be a high chloride content within the wastewater, the high corrosion effects can be countered by using an epoxy coating on the pump combined with Zinc anodes in addition to the Hard Iron components. Do I need this. How high is chloride content in digestate?

Would you ever go so far as to recommend a vertical eccentric screw pump for a difficult to pump substrate?

La clasificación de bombas entre bombas centrífugas y de desplazamiento positivo es un tema de discusión útil para mí y agradezco al escritor por esta página.

This classification is incomplete, we split our classification into Dynamic (Centrifugal pumps, Vertical centrifugal pumps, Horizontal centrifugal pumps, Submersible pumps, Fire hydrant systems) and Positive Displacement (Diaphragm pumps, Gear pumps, Peristaltic Pumps, Lobe pumps, Piston Pumps).

Much More in details that I covered the same subject. Really great information on the type of pumps, advantages, and applications.

Centrifugal Pumps Services Is Good

Thank you sir for your interest. Our seminar is open for all so that the registration is not required. you can come at seminar time.

This Pump Services is Good