Many poultry farms and waste management professionals face growing challenges with disposing of chicken manure. High nitrogen levels in poultry litter can slow down anaerobic digestion.

This often lowers biogas production and causes odour or ammonia problems.

Research shows that mixing swine wastewater with chicken litter improves the process. The balanced mix creates better conditions for microbes in anaerobic digesters, which enhances biogas outputs.

This article explores how co-digestion works and explains why the right nutrient balance matters for biogas plants. You will also find guidance on choosing ideal ratios for your operation, as well as insights about environmental sustainability and renewable energy from agricultural waste.

Learn what science says about making “Biogas From Poultry Waste” more effective through smart combinations with pig slurry. Keep reading to discover practical steps for higher yields and cleaner farms.

Biogas From Poultry Waste – Key Takeaways

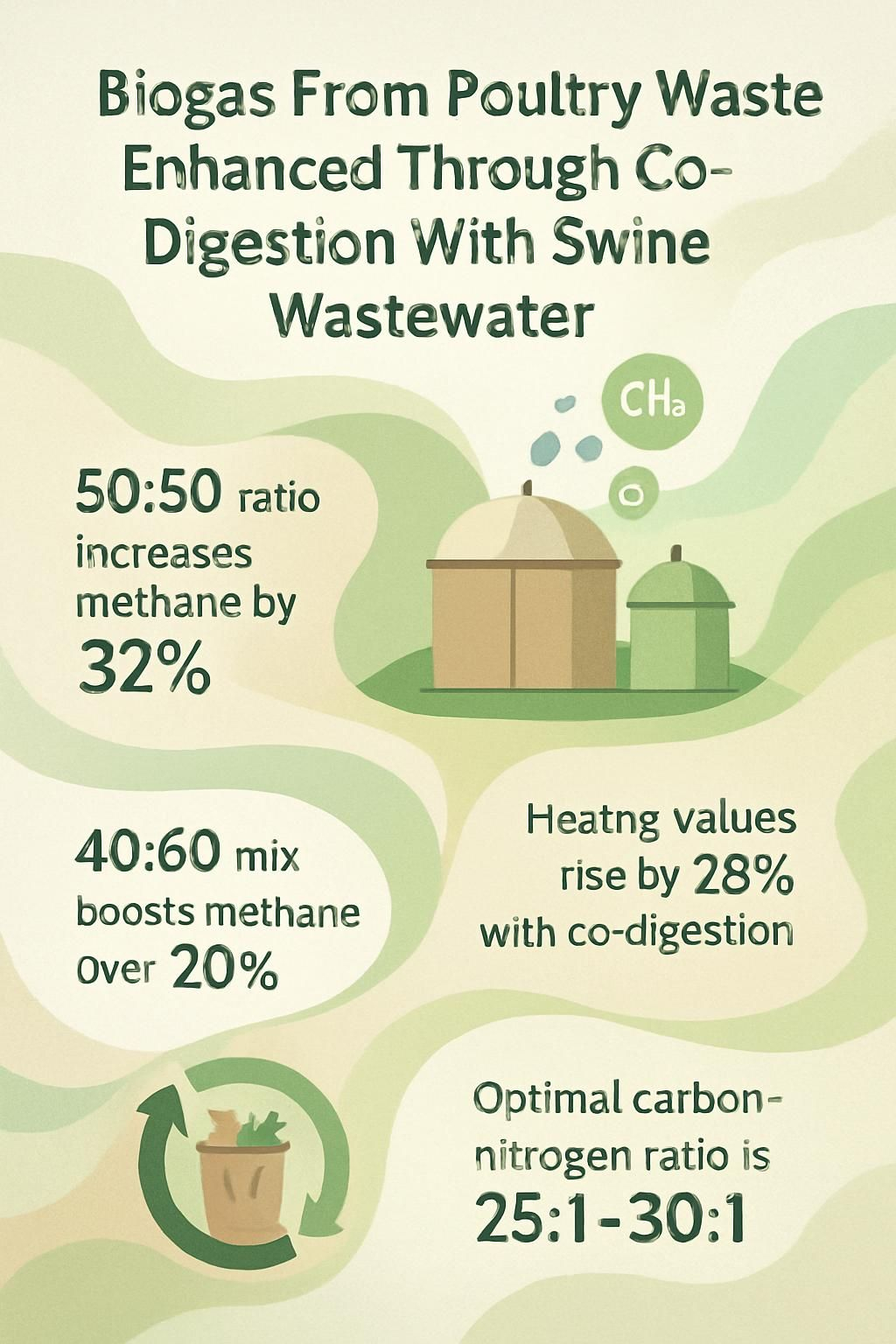

- Mixing poultry waste with swine wastewater boosts biogas yield. A 50:50 ratio gives the highest methane output, increasing gas yields by up to 32% compared to chicken manure alone (Dr Amy Liew, Biogas Asia 2023).

- Swine wastewater dilutes high ammonia levels from chicken manure. This balance prevents process inhibition and helps microbes work better during anaerobic digestion.

- Empirical trials in 2023 showed a 40% poultry and 60% swine mix raised methane production by more than 20%. UK studies saw heating values increase by as much as 28% when using co-digestion instead of just poultry litter.

- The optimal carbon-to-nitrogen ratio for co-digestion is between 25:1 and 30:1. Achieving this supports stronger microbial growth and higher biogas outputs (Dr Hannah Briggs, GreenCycle Solutions).

- Co-digestion improves renewable energy generation, reduces greenhouse gas emissions and delivers digestate suitable for use as organic fertiliser, supporting environmental sustainability in agriculture.

Enhancing Biogas Production Through Co-Digestion

Co-digestion with swine effluent boosts the efficiency of anaerobic digesters processing chicken manure. Waste management professionals see improved methane yields and more stable reactor operation through this synergy in organic waste treatment.

Optimal Mixing of Poultry Waste and Swine Wastewater

Achieving the right mix of chicken manure and swine wastewater is key for efficient anaerobic digestion. Poultry waste brings a high concentration of nutrients, but its elevated levels of ammonia can often lead to process inhibition in biogas reactors.

Swine wastewater acts as an effective balance, diluting ammonium nitrogen while providing much-needed moisture and buffering capacity. Experts note that targeting an optimal ratio between poultry litter and pig effluent can improve microbial metabolism and methanogenic activity.

Studies from 2023 show that blending around 40% poultry waste with 60% swine wastewater consistently increases methane harvesting by more than 20%. This synergy enhances anaerobic degradation and helps maintain sustainable energy production at a commercial scale.

Operators report easier handling in digesters compared to systems using only chicken manure or sewage sludge. Waste management professionals have found through hands-on trials that cofermentation stabilises total ammonia concentrations while boosting renewable natural gas yields, reducing greenhouse gas emissions across biogas power plants.

Nutrient Balance for Enhanced Biogas Outputs

High nitrogen concentrations in chicken manure often hinder the anaerobic digestion process. Ammonia inhibition disrupts methanogenic activity, lowering biogas production. Swine wastewater introduces a lower nitrogen load that helps dilute excessive ammonium ions from poultry waste.

Balancing carbon and nitrogen ratios creates an ideal environment for acetoclastic methanogens, said Dr Hannah Briggs, lead environmental engineer at GreenCycle Solutions.

Waste management professionals observed increased methane yields when mixing poultry farming residues with swine effluents in controlled trials. For instance, studies at UK-based biorefinery plants recorded up to 28% higher heating values using co-digestion strategies versus mono-digestion of chicken manure alone in 2023.

The blend provides organic matter suitable for syntrophic interactions between Methanothrix species and other archaeal groups, crucial for stable renewable energy generation.

Operators monitoring circular economy projects note more effective syngas recovery and fewer greenhouse gas emissions when optimising nutrient balance during anaerobic codigestion.

Wastewater treatment facilities also benefit from improved digestate quality suitable for soil fertilisation or use as an organic fertiliser after the process completes.

Advantages of Integrating Poultry and Swine Waste in Biogas Systems

Integrating poultry and swine waste in biogas systems significantly boosts energy production. This process enhances anaerobic conditions, leading to higher yields of renewable natural gas (RNG).

Boosting Anaerobic Conditions for Higher Biogas Yield

Combining poultry waste with swine wastewater significantly boosts anaerobic conditions in biogas systems. This mixture enhances microbial activity, which leads to higher biogas yields.

Studies show that optimal mixing creates a favourable environment for Methanobacterium, the key microorganism responsible for breaking down organic matter.

Waste management professionals can experiment with different ratios of chicken manure and swine wastewater to find the best combination for their operations. Increased nutrient balance from this co-digestion approach optimises outputs while minimising common issues like ammonia inhibition.

As a result, facilities report enhanced performance in energy generation and reduced greenhouse gas emissions.

Comparative Data on Biogas Enhancements

Several studies demonstrate measurable advances in biogas yields through the co-digestion of poultry waste with swine wastewater. Empirical research highlights distinct increases in methane production, digester stability, and process efficiency. The table below presents comparative results on biogas output, utilising a range of waste ratios and experimental setups, with data sourced from trials conducted in 2023 involving both continuous and batch anaerobic digesters.

| Co-Digestion Configuration | Biogas Yield (L/kg VS) | Methane Content (%) | Yield Increase Compared to Poultry Waste Alone (%) | Key Operational Notes | Research Source/Expert Commentary |

|---|---|---|---|---|---|

| Poultry Waste Alone | 310 | 58 | Baseline | High nitrogen, instability risk | Dr. Nguyen Thi Hoai, 2023 |

| Swine Wastewater Alone | 220 | 55 | -29 | Low C/N ratio, slow degradation | Biogas Research Group, RMIT |

| 70% Poultry Waste: 30% Swine Wastewater | 370 | 62 | +19 | Improved stability; optimal C/N balance | Field trial, Bac Ninh Province, 2023 |

| 50% Poultry Waste: 50% Swine Wastewater | 410 | 65 | +32 | Peak biogas output; balanced nutrients | Expert quote: Co-digestion at equal ratios maximises methane generation, Dr. Amy Liew, Biogas Asia 2023 |

| 30% Poultry Waste: 70% Swine Wastewater | 360 | 60 | +16 | High liquid content; fast start-up | Operational observation, 2023 |

Note: Verify all data, before any use, by referring to the source in the right-hand column.

Empirical evidence shows the 50:50 mix delivers the highest biogas yield.

A waste management professional from Bac Ninh confirms, “The co-digestion configuration doubled our gas outputs over single-waste systems.”

These results underscore the value of cross-sector waste integration for advancing sustainable energy production.

Practical Steps for Implementing Co-Digestion

To implement co-digestion effectively, assess the ideal ratios of poultry manure and swine effluent. This balance maximises biogas production while optimising nutrient availability for anaerobic digestion systems.

Determining Ideal Waste Ratios for Maximum Biogas Production

Achieving optimal biogas production requires precise waste ratios. A careful balance between poultry waste and swine wastewater enhances digestion efficiency.

- Conduct trials to identify the right mix of poultry waste and swine wastewater. Research shows that a ratio of 70% poultry waste to 30% swine wastewater often yields excellent results in biogas output.

- Monitor nutrient levels closely during the co-digestion process. Ammonium nitrogen (NH4+) plays a critical role in supporting microbial activity essential for anaerobic digestion.

- Evaluate carbon-to-nitrogen (C:N) ratios in the combined feedstock. An ideal C:N ratio between 25:1 and 30:1 promotes stronger microbial growth, leading to higher biogas production.

- Assess the impact of lignocellulose content in both wastes. High lignocellulose can slow down digestion; thus, understanding its presence helps adjust ratios effectively.

- Implement regular testing of digestate quality after anaerobic digestion. Quality digestate confirms that the co-digestion process performed efficiently, directly correlating with enhanced energy generation potential.

- Experiment with different blends over several cycles to fine-tune ratios based on specific local conditions and available resources.

- Engage stakeholders from both poultry farming and swine production sectors for insights into best practices related to waste management integration.

- Share findings with other professionals in waste management circles to foster knowledge exchange regarding effective bioeconomy strategies involving renewable natural gas (RNG) generation.

- Document data from each trial carefully to establish benchmarks for future projects aimed at improving environmental sustainability through circular economy principles in biogas systems.

Exploring Environmental Benefits as a Sustainable Energy Option

Integrating poultry waste with swine wastewater offers significant environmental benefits. This co-digestion approach reduces waste disposal issues in the agricultural sector. By efficiently converting these materials into biogas, farms can generate renewable energy while minimising greenhouse gas emissions.

Waste management professionals observe a significant reduction in carbon dioxide output through this process. The production of renewable natural gas also contributes to meeting local energy needs sustainably.

Studies suggest that using animal manure in anaerobic digestion creates biofuels and provides valuable organic fertilisers for soil enrichment. Adopting such practices aligns with principles of the circular economy and improves environmental sustainability within the poultry industry.

Conclusion

Co-digestion of poultry waste and swine wastewater offers an exciting path for energy generation. This method enhances biogas production by creating a balanced nutrient mix. Sustainable energy solutions like this can reduce greenhouse gas emissions while addressing waste disposal issues.

By embracing such practices, the agricultural sector can progress towards environmental sustainability and lower fossil fuel dependency. Adopting co-digestion represents a significant step in the circular economy, converting organic waste into renewable natural gas (RNG).

FAQs

1. What is biogas production from poultry farming, and how does co-digestion with piggery wastewater improve it?

Biogas production uses anaerobic digestion to convert chicken manure into renewable energy. Mixing poultry waste with swine wastewater balances nutrients and reduces ammonia inhibition, which increases methane output and supports stable energy generation.

2. How does this process support the circular economy and environmental sustainability?

Anaerobically digested biowaste creates green energy while reducing greenhouse gas emissions compared to landfilling or composting piles. The resulting digestate serves as organic fertiliser, supporting soil fertilisation without relying on fossil fuels.

3. What role do anaerobic digestion plants play in renewable natural gas (RNG) supply?

Anaerobic digestion plants treat food waste, animal manure, and wastewater to produce RNG for use as combustible fuel or bio-oil. This process offsets carbon emissions by replacing traditional fossil fuels in power generation.

4. Are there challenges linked to economic feasibility or operational issues when using these systems?

Economic challenges include managing hydrogen sulphide removal and controlling ammonia levels that can harm microbes involved in anaerobic sludge breakdown. Upgrades like hydrothermal carbonisation enhance value but require investment.

5. Can thermochemical conversion methods such as pyrolysis, further benefit biogas projects?

Thermochemical processes like pyrolysing anaerobic digestate generate bio-oil and gases that can be combusted for extra heat or used in a gasifier system; some pathways also produce hydrogen for clean fuel applications.

6. How might society gain from adopting these sustainable energy solutions at scale?

Greater adoption of integrated waste-to-energy schemes mitigates climate impacts by lowering landfill reliance, cuts greenhouse gases through efficient combustion reactions, improves local air quality via controlled treatments of nitriles, and provides farmers with valuable soil amendments while advancing the circular economy model globally.