Anaerobic digestion (AD) has emerged as a pivotal technology in the renewable energy sector, particularly for the sustainable production of biogas. Among the various configurations of AD systems, the two-stage anaerobic digestion process stands out for its ability to enhance both process stability and biogas yield. This comprehensive guide delves into the intricacies of two-stage anaerobic digestion, elucidating its operational advantages, the different types of systems available, and the reasons behind their efficacy in maximizing methane production.

Understanding Two-Stage Anaerobic Digestion

Anaerobic digestion is a biological process that breaks down organic matter in the absence of oxygen, producing biogas—a mixture primarily composed of methane (CH₄) and carbon dioxide (CO₂). This biogas can be harnessed as a renewable energy source, offering a sustainable alternative to fossil fuels. The AD process typically involves four key stages:

- Hydrolysis: Complex organic materials, such as carbohydrates, proteins, and fats, are broken down into simpler soluble compounds.

- Acidogenesis: The soluble compounds are further metabolized by acidogenic bacteria, producing volatile fatty acids (VFAs), alcohols, hydrogen, and carbon dioxide.

- Acetogenesis: Acetogenic bacteria convert VFAs and alcohols into acetic acid, along with additional hydrogen and carbon dioxide.

- Methanogenesis: Methanogenic archaea convert acetic acid and hydrogen into methane and carbon dioxide, completing the biogas production cycle.

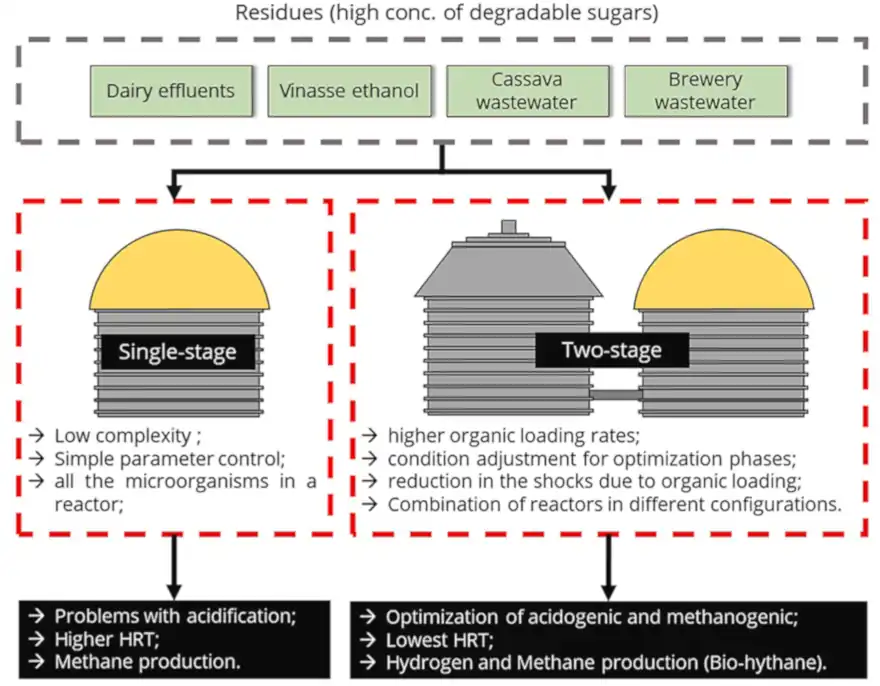

While single-stage anaerobic digestion systems integrate all these processes within a single reactor, two-stage anaerobic digestion separates them into distinct reactors, optimizing conditions for each phase and thereby enhancing overall efficiency and stability.

The Need for Two-Stage Anaerobic Digestion

Single-stage anaerobic digestion systems, while effective, often face challenges related to process stability and biogas yield. Fluctuations in feedstock composition, environmental conditions, and microbial community dynamics can lead to inefficiencies, such as reduced methane production or even system failure. Two-stage anaerobic digestion addresses these challenges by compartmentalizing the process, allowing for finer control and optimization of each stage.

Benefits of Two-Stage Systems

- Enhanced Process Stability: By isolating the hydrolysis and acidogenesis stages from methanogenesis, each reactor can be maintained under optimal conditions, reducing the risk of process disruptions.

- Increased Biogas Yield: Separate reactors enable the cultivation of specialized microbial communities tailored to each stage, enhancing the conversion of organic matter into methane.

- Improved Mass Conversion: The staged approach facilitates more complete degradation of complex substrates, maximizing the extraction of energy from the feedstock.

- Operational Flexibility: Two-stage systems allow for independent scaling of each reactor based on specific process requirements, enhancing adaptability to varying feedstock loads.

Types of Two-Stage Anaerobic Digestion Systems

Efficient two-stage anaerobic digestion systems for biogas production generally fall into two primary categories: separated reactor systems and coupled reactor systems. Each type offers unique advantages, catering to different operational needs and feedstock characteristics.

1. Separated Reactor Systems

In separated reactor systems, the hydrolysis/acidogenesis phase and the methanogenesis phase occur in physically distinct reactors. This segregation allows each reactor to be optimized for its specific biological processes.

Characteristics:

- Dedicated Conditions: Each reactor can be maintained at optimal temperature, pH, and retention time suited to the specific microbial communities involved.

- Customized Microbial Communities: Tailored microbial consortia can be established in each reactor, enhancing the efficiency of each digestion phase.

- Flexibility in Operation: Reactors can be operated independently, allowing for adjustments based on process performance or feedstock variations.

Advantages:

- Improved Process Control: Enhanced ability to monitor and adjust each stage independently leads to better overall system stability.

- Higher Biogas Yields: Optimized conditions for each phase facilitate more complete conversion of organic matter, increasing methane production.

- Reduced Inhibition Risks: Potential inhibitory substances affecting one stage are less likely to impact the other, safeguarding the overall process.

Applications:

Separated reactor systems are ideal for waste streams with complex or variable compositions, where precise control over each digestion phase is crucial for maintaining efficiency and stability.

2. Coupled Reactor Systems

Coupled reactor systems integrate the hydrolysis/acidogenesis and methanogenesis phases within interconnected reactors, often sharing some operational parameters. This configuration balances the benefits of separation with operational simplicity.

Characteristics:

- Interconnected Operation: The output of the hydrolysis/acidogenesis reactor directly feeds into the methanogenesis reactor, facilitating smooth transfer of intermediate products.

- Shared Conditions: While maintaining some level of separation, certain conditions like temperature may be consistent across both reactors to streamline operations.

- Simplified Infrastructure: Fewer separate components compared to fully separated systems, potentially reducing capital and operational costs.

Advantages:

- Balanced Efficiency: Coupled systems can achieve high biogas yields while maintaining process stability, especially suitable for medium to large-scale operations.

- Operational Simplicity: Fewer reactors and shared equipment can simplify maintenance and reduce energy consumption.

- Scalability: Modular design allows for easy expansion or modification based on changing operational demands.

Applications:

Coupled reactor systems are well-suited for facilities aiming to balance high methane production with manageable operational complexity, accommodating varied organic waste streams with moderate variability.

Optimizing Two-Stage Anaerobic Digestion for Maximum Biogas Yield

Achieving high biogas yields in two-stage anaerobic digestion involves meticulous optimization of both reactors to foster ideal conditions for each digestion phase.

Hydrolysis/Acidogenesis Reactor Optimization

- Temperature Control: Maintaining an optimal mesophilic (35-40°C) or thermophilic (50-60°C) temperature range enhances microbial activity and substrate breakdown.

- pH Regulation: Ensuring a stable pH (typically between 6.5 and 7.5) prevents acid accumulation and supports healthy microbial populations.

- Retention Time: Adjusting the hydraulic retention time (HRT) to allow sufficient time for effective hydrolysis and acidogenesis.

- Substrate Loading Rate: Balancing the organic loading rate to prevent overloading, which can lead to acid accumulation and process inhibition.

- Mixing and Aeration: Adequate mixing ensures uniform substrate distribution and efficient microbial contact, while minimizing oxygen intrusion to maintain anaerobic conditions.

Methanogenesis Reactor Optimization

- Temperature Consistency: Similar to the hydrolysis reactor, maintaining optimal temperature ranges supports methanogenic archaea activity.

- pH Stability: Keeping the pH within a narrow range (typically 7.0-8.0) is critical for methanogen health and methane production.

- Retention Time: Optimizing HRT to ensure sufficient time for methanogens to convert intermediates into methane.

- Inhibition Mitigation: Strategies to prevent accumulation of inhibitory substances like ammonia or sulfides, which can hinder methanogenic activity.

- Nutrient Balancing: Ensuring adequate nutrient availability to support the growth and activity of methanogenic microorganisms.

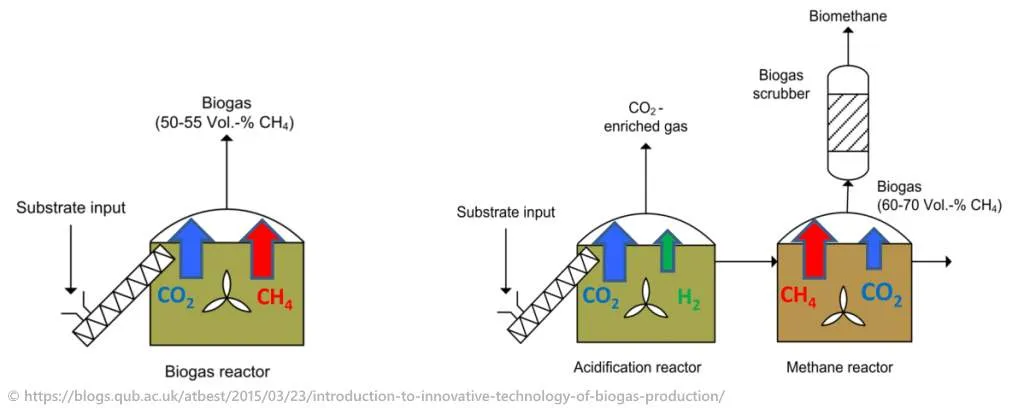

How Traditional Two Stage Anaerobic Digestion Works

The substrate (feedstock/ water mixture) is fed into the first reactor where acidification takes place leading to hydrogen production and accumulation of acids and alcohol, which are the precursors for the acetogenic microorganisms in the second stage.

The substrate (feedstock/ water mixture) is fed into the first reactor where acidification takes place leading to hydrogen production and accumulation of acids and alcohol, which are the precursors for the acetogenic microorganisms in the second stage.

The (biochemical) hydrolysis phase is either carried out batch-wise or continuously and is connected to the second methanogenic reactor. The ratio of both reactor volumes is defined by the different retention times and generation times of the bacteria. This requires smaller volumes in the hydrolysis and bigger in the methane reactor because the retention time in hydrolysis is significantly lower.

For fibrous and high solid content enriched input substrates, mixing problems could occur in the hydrolysis phase and form a floating surface layer (scum or crust). This can result in incomplete hydrolysis of the substrate.

In order to prevent this condition, proper stirring technology has to be chosen in the design phase. Due to the conversion of solid carbon into the liquid phase, a liquefaction of the substrate occurs.

The biogas produced in the first stage contains a high percentage of carbon dioxide and some hydrogen. The second stage tank provides a higher quality biogas than a single-stage AD plant. It is also reported that plant stability is better for two-stage anaerobic digestion plants.

In this discussion, it is important to be aware of the fact that the hydrolysis referred to here is “biochemical hydrolysis” and NOT the “Thermal Hydrolysis“ (high temperature and pressure hydrolysis) stage applied often to sewage sludges, as the first stage (e. g. Cambi Hydrolysis Process). “High temperature and pressure hydrolysis” is normally only used for the breakdown of biomass (such as sewage sludges) which would otherwise mostly pass right through any biogas plant run at normally applied (mesophilic) temperatures

Enhancing Process Stability in Two-Stage Systems

Process stability is paramount for the consistent operation of anaerobic digestion systems. Two-stage configurations inherently bolster stability, but additional strategies can further mitigate risks:

1. Buffering Capacity Enhancement

Incorporating buffering agents or adjusting the feedstock composition can help maintain pH stability, preventing acidification that could disrupt microbial activity.

2. Monitoring and Control Systems

Implementing advanced monitoring systems to track key parameters (e.g., pH, temperature, volatile fatty acids) allows for real-time adjustments, ensuring optimal operating conditions. In this, real-time FOS/TAC analysis is increasingly being used to control feed rates, plus trace and chemical/ enzyme dosing.

Redundancy and Resilience Planning

Designing systems with redundancy in critical components or flexibility to handle feedstock variations enhances the resilience of the digestion process against unforeseen disruptions. Grit and plastics removal prior to digestion is used to reduce biogas plant outages.

Overall Energy Recovery Can be Best from 2 Stage Biogas Plants

Researchers point out that the supremacy of two-stage on traditional single-stage anaerobic digestion (AD), in terms of overall energy recovery (ER) from biomass has frequently been proved.

It is due to the different growth rates, preferences, and requirements of the microorganism species involved in each step, that physical separation in two independently performing reactors is an option that enables specific conditions for the microbiology at each stage to be set to optimize output.

The first stage reactor is often called the hydrolytic reactor, of a two-stage AD system.

Anaerobic digestion (AD) is the biological degradation of organic material in the absence of air.

An anaerobic digester is a man-made system that harnesses this natural process to treat waste, produce biogas that can be converted to heat and electricity, and anaerobic digestate, a soil-improving material.

Anaerobic Digestion (AD) is the preferred stabilization process for the treatment of wastewater sludges and organic wastes. The process provides volume and mass reduction and delivers valuable renewable energy with biogas production.

A company called Arrowbio is one of the best-known internationally, for using two-stage anaerobic digestion within its process designs.

Case Studies: Successful Implementation of Two-Stage Anaerobic Digestion

Case Study 1: Municipal Waste Treatment Facility

A municipal waste treatment facility adopted a two-stage anaerobic digestion system to manage organic waste efficiently. By separating the hydrolysis and methanogenesis phases, the facility achieved a 25% increase in biogas production compared to their previous single-stage system. Additionally, the improved process stability reduced downtime and maintenance costs, demonstrating the economic and operational benefits of the two-stage approach.

Case Study 2: Agricultural Biogas Plant

An agricultural biogas plant processing livestock manure integrated a two-stage anaerobic digestion system to enhance methane yields. The optimized separation allowed for better handling of high-nitrogen feedstocks, mitigating ammonia inhibition and sustaining high biogas production rates. This implementation not only increased energy output but also provided a reliable renewable energy source for the agricultural operations.

Future Perspectives and Innovations in Two-Stage Anaerobic Digestion

The landscape of anaerobic digestion continues to evolve, with ongoing research and technological advancements aimed at further optimizing two-stage systems.

Integration with Renewable Energy Technologies

Combining two-stage anaerobic digestion with other renewable energy sources, such as solar or wind power, can create hybrid systems that maximize energy efficiency and sustainability.

Advanced Microbial Engineering

Genetic and metabolic engineering of microbial communities holds promise for enhancing the efficiency and resilience of both digestion stages, leading to higher methane yields and greater process stability. Advanced H₂S management also reduces sulphur build up with the risk of digester tank corrosion above the water line.

Digitalization and Automation

Incorporating digital technologies and automation in monitoring and controlling two-stage anaerobic digestion systems can lead to more precise management, predictive maintenance, and adaptive optimization, further improving performance and reliability.

Why Choose Our Two-Stage Anaerobic Digestion Solutions?

At IPPTS Associates, we put together teams of process and environmental engineers experienced in designing and implementing advanced anaerobic digestion systems tailored to our client's unique needs. Our expert designers ensure that our biogas plants, when tendered constructed by specialised biogas contractors achieve optimal process stability and maximize methane production, delivering both economic and environmental benefits.

Our Services Include:

- Customized System Design: Tailored AD systems to fit your specific feedstock and operational requirements.

- Installation and Commissioning: Comprehensive support from system setup to operational launch.

- Ongoing Maintenance Supervision and Support: Ensuring your system remains efficient and reliable through regular maintenance and expert support.

- Consultancy and Optimization: Expert advice to enhance your existing AD systems for improved performance and higher biogas yields.

Get Started Today!

Unlock the full potential of your organic waste with our state-of-the-art two-stage anaerobic digestion solutions. Contact us today to schedule a consultation and take the first step towards a more sustainable and profitable energy future.

Learn More About Our Consultancy Services

Two-Stage anaerobic digestion in …” from www.sciencedirect.com and used with no modifications.

Figure 1: A schematic representation of a two-stage anaerobic digestion system.

Conclusion

Two-stage anaerobic digestion represents a significant advancement in the realm of biogas production, offering enhanced process stability and increased methane yields through the strategic separation of digestion phases. By optimizing each stage independently, these systems not only maximize energy recovery from organic waste but also ensure robust and resilient operations. As the demand for sustainable energy solutions grows, two-stage anaerobic digestion stands out as a pivotal technology driving the transition towards a greener and more efficient energy landscape.

Embracing this innovative approach can lead to substantial economic and environmental benefits, positioning your operations at the forefront of renewable energy advancements. Whether you are managing municipal waste, agricultural by-products, or industrial organic streams, two-stage anaerobic digestion offers a reliable and scalable solution to meet your biogas production goals.

For more information on how two-stage anaerobic digestion can transform your waste management and energy production processes, reach out to our team of experts at [Your Company Name]. Together, we can build a sustainable future powered by renewable biogas.

[Page first published 6 November 2014, subsequently updated January 2018 and March 2025.]

Why limit your discussion to just the wet/wet anaerobic digestion two stage AD Plant design options? There is also the possibility of two stages dry/wet. The GICON Process is a two-stage dry-wet anaerobic digestion process operated in batch mode. Take a look at http://www.gicon-engineering.com ‘s digester design.

Two stage digesters cost more to build than the single stage plants which are by far the most common. A new technology option is to add a pre-treatment stage which can pay for itself because it removes ammonia and phosphorus, allowing high ammonia feedstocks to be used and for an additional product profit stream. See https://anaerobic-digestion.com/phosphorus-crisis-nutrient-recycling-anaerobic-digestion/

I am looking for 2 stage anaerobic digestion plant designer/ installers. So far I have found just ArrowBio’s process. It would be useful if this page contained a list of all the top AD plant contractors which offer their own 2 stage AD facility designs. Nevertheless, do let me say I like this website.

Chris. In this case (and also I notice other writers), talk about 2 stage anaerobic digestion but I am unclear. The hydrolysis stage, is that counted as a stage? You do not mention this so it i unclear. Don’t mind me. Keep posting. Congrats generally on website.

The term ‘Two Stage’ refers to the separation of the entire process physically by using two different tanks that are operating to two different sets of conditions. In anaerobic digestion there are four stages overall but they can be split into two broader groups. Generally, the groups will be categorised into the Acid forming phase (Hydrolysis and Acidogenesis stages 1 and 2) and Methane forming phase (Acetogenesis and Methanogenesis stages 3 and 4). In the above work I think it is split into the two groups with one contains 3 stages and the other 1 stage (Group 1 [Hydrolysis, Acidogenesis, and Acetogenesis]: Group 2 [Methanogenesis]).

I wouldn’t agree with the grouping listed. The bacterial biome (for want of a better word) present in the Acid forming phase prefer conditions more acidic meaning certain types of bacteria grow. The Methane forming stage (I am referring to Acetogenesis and Methanogenesis here) bacteria proliferate under the same conditions as each other but are not as tolerant to conditions present in the Acid forming bacteria. However, with biology being biology, nature will adapt and every reactor setup is different.

So in answer to your, yes hydrolysis is counted as a stage. It occurs within the first stage (with acidogenesis) of the two stage process.

Did you notice that the original two-stage biogas company ArrowBio still has its original website, but in fact they did seem to be trading as arrowbio-global until recently [2020]. There must be a story about that… Just wondering?

Hello I am so thrilled I found your site, I didn’t really expect to find much written about biogas. I didn’t think many people knew about it, although we’ve always done it on our smallholding.

Regardless I am here now and would just like to say thanks for a very revealing publication, and a altogether interesting website. keep up the superb job. what’s an URL?

Forgive my lack of knowledge on the topic, however I should ask: the bacteria produce CH4, then there is a lot of hand-waiving stating it will produce electrical power. How does the gas produce electrical power, and more significantly, how is the production of CH4, which is a powerful GHG, avoided going into the environment throughout the procedure?

An impressive share, I have sent this on to a colleague who will doing some further analysis on this. We might use this and adapt our plant to 2 stages after considering the 2 stage biogas process further. He actually bought me a beer last night, to say thanks. Meanwhile would you mind updating your blog with more details? It’s helpful for us.