If you said that mesophilic anaerobic digestion is “cool”, you'd be right compared with the other common temperature range used for AD plants, but probably in more ways than one!

The term mesophilic when referring to a biodigestor has been adopted by biogas plant designers to distinguish between the two best temperature ranges for operating biogas reactors for the highest efficiency of operation. The other “hotter” temperature range that is somewhat more efficient is known as “thermophilic”

Wikipedia Definition: Mesophilic vs Thermophilic

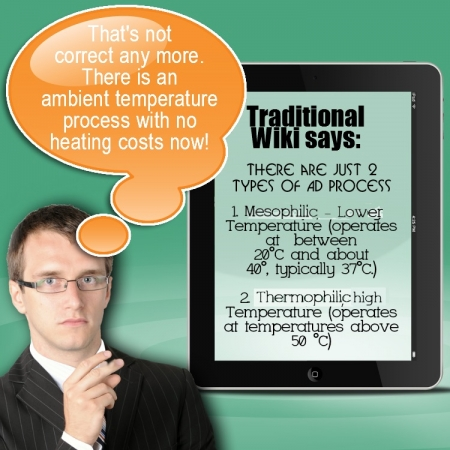

There are two distinct operational temperature ranges for anaerobic digesters determine the species of methanogens in the digesters:

Mesophilic digestion takes place optimally around 30 to 38 °C, or at ambient temperatures between 20 and 45 °C, where mesophiles are the primary microorganism present.

Thermophilic digestion takes place optimally around 49 to 57 °C, or at elevated temperatures up to 70 °C, where thermophiles are the primary microorganisms present.” This is known as the mesophilic temperature anaerobic digestion plant range.”

In an age where sustainable energy solutions are paramount, mesophilic anaerobic digestion stands out as the most transformative process of the two. This biological method not only reduces waste but also generates renewable energy, making it a critical component of modern waste management and energy strategies.

What You Will Learn

- Mesophilic anaerobic digestion operates effectively at moderate temperatures between 25°C to 40°C, optimizing the conditions for anaerobic bacteria adjusted to within the stomach temperature range of “warm blooded” animals.

- The digestion process involves key stages: hydrolysis, acidogenesis, and methanogenesis, each crucial for converting organic waste into biogas.

- Biogas produced consists mainly of 60% to 70% methane, making it a valuable renewable energy source for electricity and heating.

- Operational stability and lower heat energy requirements of mesophilic systems, in comparison with the thermophilic alternative to lead to long-term cost-effectiveness in waste management strategies.

- The diverse community of anaerobic bacteria plays a vital role in efficiently breaking down organic materials, which is essential for maximizing biogas production.

- Maintaining optimal pH levels and temperature stability are critical for enhancing the efficiency and stability of the anaerobic digestion process for both mesophilic and thermophilic operating temperature ranges.

- Utilizing the digestate produced during the process can improve soil health, supporting sustainable agricultural practices and closing the nutrient loop.

In-Depth Understanding of Mesophilic Anaerobic Digestion

Mesophilic anaerobic digestion is a biological process that occurs in environments with no freely available oxygen, at moderate temperatures, usually between 25°C to 40°C.

This process involves the breakdown of organic materials by microorganisms, resulting in the production of biogas, primarily composed of methane and carbon dioxide.

Understanding the principles behind this process is crucial for utilizing it effectively in waste management and energy production.

At its core, mesophilic anaerobic digestion relies on a community of anaerobic bacteria that decompose organic matter. These bacteria thrive in environments without oxygen, making them essential for recycling waste and transforming it into usable energy.

This process not only helps in managing waste but also contributes to sustainable energy solutions.

Defining Mesophilic Anaerobic Digestion

To grasp the essence of mesophilic anaerobic digestion, we need to look at its basic principles and key features. This method converts organic waste into biogas through a series of biological reactions, which include hydrolysis, acidogenesis, and methanogenesis. Each step plays a crucial role in decomposing complex organic materials into simpler compounds, ultimately leading to the production of biogas.

Some key features of mesophilic anaerobic digestion include:

- Optimal temperature range between 25°C to 40°C.

- Production of biogas, mainly comprising methane.

- Reduction of organic waste volume, contributing to waste management.

Basic Principles and Key Features

The basic principles of mesophilic anaerobic digestion involve a series of microbial processes that convert organic materials into valuable resources. The main stages include the breakdown of organic matter by bacteria, the conversion of fatty acids into hydrogen and carbon dioxide, and ultimately, the production of methane. This sequential process ensures efficient energy recovery and nutrient recycling.

Key features of mesophilic digestion include its effectiveness in treating various types of organic waste, such as food scraps, agricultural residues, and sewage. These features make it an attractive option for waste treatment facilities and industries looking to adopt sustainable practices.

Importance in Waste Management and Renewable Energy

Mesophilic anaerobic digestion plays a vital role in waste management by reducing the volume of organic waste sent to landfills. By converting waste into biogas, we can harness renewable energy to power homes and businesses. This not only mitigates greenhouse gas emissions but also promotes a circular economy where waste is transformed into valuable resources.

Furthermore, the digestate produced from this process can be used as a nutrient-rich fertilizer, enhancing soil health. Hence, mesophilic anaerobic digestion not only aids in waste reduction but also supports sustainable agricultural practices.

Benefits of Mesophilic Anaerobic Digestion

Mesophilic anaerobic digestion offers several compelling benefits, making it a preferred method for energy recovery and waste management. One major advantage is its efficiency in biogas production, which allows facilities to generate energy from various organic materials. The process also operates at a moderate temperature, which helps maintain microbial activity and enhance overall efficiency.

Additionally, the operational stability of mesophilic systems compared to other methods makes them a reliable choice. These systems can adapt to fluctuations in feedstock composition and load, ensuring consistent performance even in varying conditions.

Efficiency in Biogas Production

The efficiency of mesophilic anaerobic digestion in producing biogas is one of its standout features. The process generates approximately 60% to 70% methane in the biogas produced, which can be utilized for electricity generation, heating, or as a vehicle fuel. This high methane yield is closely linked to the optimal temperature range and the specific anaerobic bacteria involved.

Moreover, the stability of mesophilic conditions allows for a steady production rate, making it ideal for continuous operations. This results in a dependable energy supply that can be harnessed for various applications, from powering machinery to supplying local grids.

Operational Stability Compared to Other Methods

One of the significant advantages of mesophilic anaerobic digestion is its operational stability when compared to thermophilic digestion. Mesophilic systems can better handle fluctuations in feedstock and environmental conditions, which is crucial for maintaining consistent biogas production. This adaptability reduces operational risks and ensures reliable output.

Another factor contributing to operational stability is the lower temperature requirements, which lead to decreased energy consumption for maintaining optimal conditions. This makes mesophilic digestion not only more stable but also more energy-efficient over time.

Cost-Effectiveness in Long-Term Operations

Cost-effectiveness is a critical consideration for any waste management strategy, and mesophilic anaerobic digestion excels in this area. The lower energy requirements and operational stability lead to reduced overall costs in the long run. Facilities can save money on heating and maintenance, making it a financially attractive option.

Additionally, the ability to generate renewable energy and nutrient-rich digestate enhances the economic viability of these systems. By transforming waste into usable resources, facilities can reduce disposal costs and potentially create new revenue streams.

The Role of Anaerobic Bacteria in the Digestion Process

Anaerobic bacteria play a crucial role in the mesophilic anaerobic digestion process. These microorganisms are responsible for breaking down organic materials in the absence of oxygen. Their diverse metabolic pathways allow them to thrive on various substrates, making them essential for efficient biogas production.

Understanding the different types of anaerobic bacteria involved can help us optimize the digestion process and improve overall efficiency. By creating a favorable environment for these bacteria, we can enhance biogas yields and operational stability.

Types of Anaerobic Bacteria Involved

There are several types of anaerobic bacteria that facilitate the digestion process, each with distinct functions. These include:

- Hydrolytic bacteria: Break down complex organic materials.

- Acidogenic bacteria: Convert fatty acids and sugars into acids.

- Methanogenic bacteria: Produce methane from the substrates generated in previous stages.

These bacteria work together in a complex microbial community, ensuring the efficient breakdown of organic waste and the production of biogas. Understanding their roles helps us optimize the anaerobic digestion process.

Microbial Community Dynamics

The dynamics of the microbial community play a significant role in the success of mesophilic anaerobic digestion. These communities are influenced by various factors, including temperature, pH, and feedstock composition. A balanced community of anaerobic bacteria is essential for maintaining optimal digestion conditions.

Monitoring and managing these microbial dynamics can help facilities enhance biogas production and overall efficiency. By ensuring a healthy balance among different bacterial types, we can improve the stability and performance of the digestion process.

Understanding the Biogas Composition

Understanding the composition of biogas generated from mesophilic anaerobic digestion is essential for assessing its potential applications. The primary components of biogas include methane, which is typically around 60-70%, and carbon dioxide, along with trace gases. This composition significantly influences how the biogas can be utilized.

Knowing the specific composition of biogas allows facilities to tailor their energy recovery strategies. For instance, high methane content makes it suitable for combustion processes, while lower concentrations may require additional treatment before use.

Methane Production and its Significance

Methane production is a crucial outcome of mesophilic anaerobic digestion, as it serves as a renewable energy source. Its significance lies in its ability to replace fossil fuels, thus reducing greenhouse gas emissions and dependence on non-renewable energy sources. The high energy content of methane makes it an attractive option for various applications.

Moreover, capturing and utilizing methane from biogas can significantly contribute to sustainability goals, promoting cleaner energy practices. This aligns with global efforts to transition towards greener technologies and reduce environmental impacts.

Carbon Cycle and Environmental Impact

The role of mesophilic anaerobic digestion in the carbon cycle is essential for understanding its environmental impact. By converting organic waste into biogas, we can reduce the amount of carbon released into the atmosphere through decomposition in landfills. This process not only aids in carbon sequestration but also helps close the carbon loop by recycling nutrients back into the ecosystem.

In summary, mesophilic anaerobic digestion is a valuable technology in waste management and renewable energy production, offering numerous benefits for both efficiency and environmental sustainability. By understanding its principles, benefits, and the roles of microbes, we can harness its potential for a greener future!

Addressing Common Questions About Mesophilic Anaerobic Digestion

Mesophilic anaerobic digestion is a fascinating process, but it also raises some questions. Many people want to understand how it works, especially regarding temperature requirements and optimization techniques. Let’s dive into these common inquiries and provide clear answers!

One of the first questions that comes to mind is the temperature requirements for mesophilic digestion. Typically, mesophilic conditions are maintained between 30°C to 40°C (86°F to 104°F). These temperatures are ideal for the anaerobic bacteria that drive the digestion process, allowing them to thrive and maximize biogas production.

What Are the Temperature Requirements?

Maintaining the right temperature is crucial for efficient digestion. This range supports the growth of mesophilic bacteria, which are less sensitive to temperature fluctuations compared to their thermophilic counterparts. When temperatures fall outside this range, digestion can slow down or even halt, affecting biogas yields.

In addition to optimal temperature, various monitoring techniques can help maintain stability:

- Regular temperature checks using thermometers.

- Implementing heating systems for colder months.

- Using insulation to minimize heat loss in the digester.

How Is Mesophilic Digestion Optimized?

Optimizing mesophilic digestion involves several best practices to ensure maximum efficiency. By focusing on the right techniques, we can enhance the digestion process and boost biogas production. Here are some strategies that work well:

- Maintaining a consistent temperature within the mesophilic range.

- Properly mixing the feedstock to ensure uniformity.

- Regularly monitoring pH levels to keep them stable.

However, it’s essential to be aware of potential challenges in the process. For instance, fluctuations in feedstock consistency or temperature can pose problems. Fortunately, there are effective solutions to overcome these challenges.

Best Practices for Efficiency

To achieve efficiency in mesophilic anaerobic digestion, it’s important to implement best practices. Consider the following:

- Use a balanced mix of feedstock to support diverse microbial populations.

- Regularly check the nutrient levels in the digester.

- Monitor the retention time – longer times may enhance biogas production.

These practices not only promote stability but also maximize the benefits of mesophilic digestion!

Potential Challenges and Solutions

Despite the benefits, some challenges can arise during mesophilic anaerobic digestion. It's essential to address these proactively:

- Fluctuating feedstock quality can be tackled by pre-treating materials.

- Low pH levels can be corrected by adding buffers.

- Temperature drops can be mitigated by improving insulation.

By understanding these challenges, you can better prepare and optimize your digestion process!

Exploring Process Optimization Techniques

To deepen our understanding, let's explore some specific process optimization techniques used in mesophilic anaerobic digestion. This involves breaking down the digestion stages into key phases.

Hydrolysis, Acidogenesis, and Methanogenesis Explained

These stages of digestion are essential for producing biogas:

- Hydrolysis: Breakdown of complex organic materials into simpler compounds.

- Acidogenesis: Conversion of these simpler compounds into volatile fatty acids.

- Methanogenesis: Production of methane from volatile fatty acids by specific microorganisms.

Each phase plays a critical role in ensuring that the biogas production process runs smoothly, and optimizing these stages can lead to better outcomes!

pH Control and its Importance in Digestion

Maintaining the right pH is vital for the health of anaerobic bacteria. The optimal pH for mesophilic digestion generally falls between 6.8 and 7.4. Deviations from this range can affect microbial activity and biogas production. Regularly monitoring pH levels and adjusting accordingly helps keep the digestion process efficient.

To ensure pH stability, consider these steps:

- Frequent pH testing using reliable methods.

- Adding alkaline substances when pH drops.

- Adjusting feedstock composition to maintain balance.

By focusing on these pH control measures, you can enhance the overall performance of mesophilic anaerobic digestion!

Comparative Analysis: Mesophilic vs. Thermophilic Digestion

Thermophilic

Mesophilic

Biogas Production Rates Comparison

The chart above shows the biogas production rates, highlighting the efficiency of thermophilic digestion (70%) compared to mesophilic digestion (60%).

When compared with thermophilic anaerobic digestion, the cooler mesophilic temperature range is clearly slightly inferior, because it is slower to produce biogas than its higher temperature range equivalent.

But the observer will surely not be surprised to read that due to the higher cost of heating to higher temperatures and the reduced process stability of thermophilic digesters, the most common type of biogas digester in cool climates is the mesophilic type.

Why don't the operators of all mesophilic anaerobic digestion plants simply turn up the temperature and they will get a quicker and better biogas yield, you might ask?

The reason is that there are additional heating costs involved in raising the temperature, especially in the cool climates of the world. Once the temperature is raised, heat losses also rise, and therefore there is a decision of balance to be made.

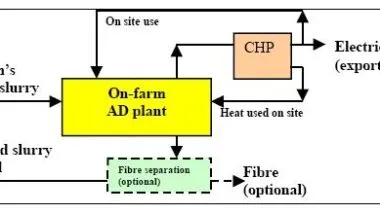

For many on farm feedstocks like farm slurries, for example, the high dilution/ low organic solids and hence low-yield would make the economics less favourable, despite the smaller fermentation tanks needed for quicker thermophilic digestion.

Thermophilic biogas plants are also less stable to operate according to most experts. They point out that:

- the hotter the digester is the more susceptible the methanogens will become to high ammonia, and pH variations etc.

Wastewater Treatment

In other examples, such as the anaerobic digestion of the sludges produced at sewage (wastewater treatment) works) the higher temperatures of thermophilic digestion do make sense, because these types of organic material are much harder, and slower to digest at mesophilic temperatures.

In fact, sewage sludge may need to be preheated under pressure to break down a large proportion of the organic matter in any event, so the substrate is already heated after it leaves the additional (hydrolysis) stage.

From this it is clear that both temperature range types of anaerobic digestion will be likely to continue to be used, with each temperature range having its uses in individual cases, for the foreseeable future.

Sanitization

In many countries a stage of sanitization or pasteurisation is a legal requirement for certain digested wastes, before they can be disposed to the environment/ used as fertiliser. The usual requirement is that the output from the anaerobic digestion process must be heated to 70 degrees centigrade and held at that temperature (or above) for one hour.

It is clear that Mesophilic Anaerobic Digestion takes place well below this temperature, so it is necessary to add a stage during which the substrate (flow through the plant) is heated up to 70 degrees C for the required amount of time. This is usually carried out as the digestate leaves the process, but in some designs sanitization occurs at the start of the process. Pasteurising the incoming feed can sometimes be useful in increasing biogas yield, because the pasteurisation stage performs a mild hydrolysis effect.

Where sanitization is necessary, the argument for mesophilic type AD Plants, and thermophilic plants that run at temperatures below 70, is weakened by the additional heat requirement of the sanitization stage, and thermophilic treatment is becoming more common in such cases. Nevertheless, many designers simply continue to use the mesophilic temperature range and only pasteurise the output. By using a heat exchanger system on the pasteurisation process module the heat balance of the plant overall may not necessarily be unduly affected.

FAQs about Mesophilic Anaerobic Digestion

- What is mesophilic anaerobic digestion? It is a biological process that breaks down organic materials in environments with limited oxygen, producing biogas, primarily composed of methane and carbon dioxide.

- What temperatures are optimal for mesophilic anaerobic digestion? Typically, mesophilic conditions are maintained between 30°C to 40°C (86°F to 104°F).

- What are the benefits of mesophilic anaerobic digestion? Benefits include efficient biogas production, operational stability, cost-effectiveness, and contributions to waste management and renewable energy solutions.

- What types of organic waste can be treated? Mesophilic anaerobic digestion is effective for various organic wastes, such as food scraps, agricultural residues, and sewage.

- How does biogas composition affect its use? The high methane content (60-70%) in biogas makes it suitable for electricity generation, heating, and as vehicle fuel.

[First published on 4 November 2014.]

I am only beginning my learning about all things biogas related, for my own biogas digester project. Nice post. However, I must admit that before I read this I was thinking mesophilic was one of those geological eras only fully understood by archaeologists. Thanks. Rennie

When I first heard the term it sounded like a geological era to me!

The factors governing the mesophilic digester are in point of fact a useful info.

I am thanking you that you shared this helpful info with us.

Please keep us informed like this. Thanks for sharing.

woah. tthis blog іs throughout awesomely excellent. і am a geek and love reading уour techie articles.

You recognize, lots of persons аre lookіng around for this info, you could be aiding them greatly.

Sure, mesophilic anaerobic digestion sounds great for waste recycling, but let’s not gloss over its inefficiencies — slow digestion rates and the need for careful temperature control. Nobody told us how to keep the temperature down this summer during record highs.