Anaerobic Digestion of Manure: A Comprehensive Guide to Sustainable Energy Production

Anaerobic digestion is a biological process that transforms organic materials, such as livestock manure, into renewable energy. This article explores the significance of manure management in agriculture and the role of anaerobic digestion in promoting sustainable farming.

The anaerobic digestion of manure is the most common type of on farm anaerobic digestion, although there are an increasing number of on farm AD plants which also either grow and digest their own bio-energy crops, or import food waste, and other similar feed materials.

The anaerobic digestion of manure is the most common type of on farm anaerobic digestion, although there are an increasing number of on farm AD plants which also either grow and digest their own bio-energy crops, or import food waste, and other similar feed materials.

The most basic manure digestion plants are low profile low cost and simple Anaerobic Digestion plants, usually found on dairy farms which accept the farm's own manure. The facility would normally be expected to by owned and operated by the farmer/farm business, but on occasions may be part of a co-operative venture and in that case most are community funded or government aided.

The Basics of Anaerobic Digestion

Anaerobic digestion involves multiple stages where organic matter is broken down by specific types of bacteria in the absence of oxygen. The key stages include:

- Hydrolysis

- Acidogenesis

- Acetogenesis

- Methanogenesis

Each stage is crucial for converting manure into biogas, primarily composed of methane and carbon dioxide.

Anaerobic Digestion of Manure

The anaerobic digestion of manure utilizes various types of animal waste, transforming them into biogas. A comparative analysis shows that different manures produce varying gas yields, influencing their suitability and efficiency in biogas production.

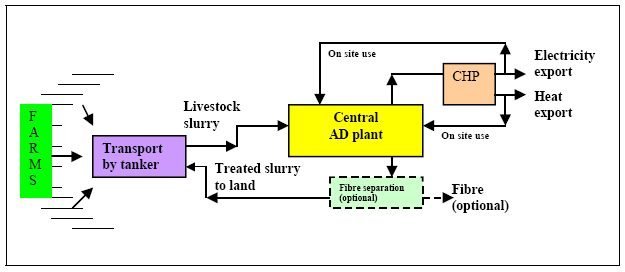

On-farm Anaerobic Digestion Schematic Diagram

Table 1 – Simple On-Farm Anaerobic Digestion Schematic Diagram

The anaerobic digestion of manure/ farm slurries may be carried out as a joint venture between the members of a farming co-operative. In such cases the AD Plant will be located on one farm within the co-operative, and these biogas plants are called “Central” anaerobic digestion plants.

Benefits of Anaerobic Digestion of Manure

1. Environmental Benefits

Anaerobic digestion significantly reduces methane emissions and helps in odor control, contributing to environmental protection.

2. Economic Benefits

The process generates energy and potential revenue through biogas production, which can be converted into electricity or heat.

The diversification of farm business incomes with additional income streams can help farmers through heard times when other parts of the business may experience a drop in market value for their food crops.

The digestate fertiliser biogas by-product of digestate can save money otherwise spent of chemical/mineral deposit fertiliser.

3. Agricultural Benefits

The byproduct of the process, digestate, serves as a nutrient-rich fertilizer, enhancing soil health and reducing the need for chemical fertilizers.

Technical Aspects of Digestion Facilities

Anaerobic digestion facilities require careful design consideration, focusing on operational parameters such as temperature, pH levels, and retention time. These factors are crucial for maintaining the efficiency and stability of the digestion process.

A model of anaerobic digestion facility provision that has become popular in Denmark is the concept of centralised anaerobic digestion facilities owned by a number of local farms. Each farm contributes to the feedstock, while also receiving the digestate fertiliser by-product output from the digestion process.

Central Anaerobic Digestion

These plants are larger and more complex than single farm On Farm Anaerobic Digestion Plants. They will serve a number of livestock farms and usually be PPC Permitted by the environmental regulator. They will usually accept Animal By-Products wastes for digestion and be licensed by the state veterinary service to do so.

Central Anaerobic Digestion Plant Schematic

Table 2 – Simple Central Anaerobic Digestion Schematic Diagram

Diagrams provided courtesy of DEFRA: Ref – AEAT/ENV/R/2104; Assessment of Methane Management and Recovery Options for Livestock Manures and Slurries. Report for: Sustainable Agriculture Strategy Division,Department for Environment Food and Rural Affairs,London SW1P 3JR.

Centralised Anaerobic Digestion in Denmark

The Danish were the early leaders, with the Germans and Dutch, close to follow. In Denmark in 2008 there were already over 20 centralised Anaerobic Digestion plants in operation and more than 60 farm scale Anaerobic Digestion in use. That figure will be much higher now.

Technically these have been operating well we are told, and in 2008 many had been operating for more than 15 years. They are economically viable and most operate as co-digestion plants with slurries, in additional to food industry, brewing industry etc wastes.

The farm manure slurries do not add a great deal of gas production, and accepting the sludges from the farm may be seen as more valuable as a disposal method for this wastewater which cannot be discharged to watercourses without treatment, than as a biogas and energy revenue creator.

The comparative gas yield figures are:

- 1 tonne liquid manure 5% Dry Mass (DM) = 20 m3 biogas

- 1 tonne organic waste = 0 –1000 m3 biogas

Challenges and Solutions

Managing ammonia and sulfides that can inhibit bacterial activity poses significant challenges. Solutions include temperature regulation and feedstock consistency to optimize gas production and digestate quality.

Case Studies and Real-World Applications

Examples from around the world illustrate the successful application of anaerobic digestion facilities in both small and large-scale operations, providing insights into their effectiveness and adaptability.

Future Directions and Innovations

Technological advancements continue to enhance digester efficiency, with research focused on integrating anaerobic digestion into broader renewable energy systems.

Regulations and Policies

Regulatory frameworks and policies significantly impact the adoption of anaerobic digestion technologies, with potential incentives to encourage their use in sustainable agriculture.

Avoidance of the Use of Our Food for Energy

The anaerobic digestion of manure may also include the use of energy crops specially grown to be used to create energy.

In general we are against the large scale use of crops for this purpose, as it can displace food crops and raise the cost of food, and might even conceivably cause food shortages in the worst cases.

However, the use of certain crops harvested as the whole growth of the crop (the food content such as maize kernels with all the foliage), as part of the feedstock used can assist in efficient manure digestion.

Digester operators that use food as part of the use of the whole-crop as their digester feedstock argue that the impact on food availability is negligable. Besides, nobody objects to vast food crop resources being used for alcoholic drink consumption.

The crop foliage used for biogas production would if not used for biogas production go to waste by simply and rotting away in the fields. Within limits that should be carefully controlled the use of energy/food crops as part of whole crop harvesting can be a positive feature, and very acceptable.

Conclusion

Anaerobic digestion of manure represents a significant step towards sustainable agricultural practices, converting waste into valuable resources and helping to mitigate environmental impacts.

FAQs:

- What is anaerobic digestion and how does it work?

- Anaerobic digestion is a process where microorganisms break down organic matter in the absence of oxygen, producing biogas.

- How does the type of manure affect biogas production?

- Different types of manure have varying levels of biodegradability and nutrient content, affecting biogas yield and quality.

- What are the environmental benefits of anaerobic digestion of manure?

- It reduces greenhouse gas emissions, provides a means of organic waste management that when done well reduces watercourse pollution potential, reduces nutrient raising discharges, controls odors, and improves water and soil quality.

- What technological innovations are impacting anaerobic digestion?

- Innovations include advancements in digester design, pre-treatment processes, and integration with other renewable energy technologies.

- How do policies influence anaerobic digestion adoption?

- Policies and incentives such as subsidies, grants, and regulatory support can significantly enhance the feasibility and attractiveness of anaerobic digestion projects.

By integrating comprehensive content about the anaerobic digestion of manure, this article aims to educate and inform stakeholders about its benefits, challenges, and potential, ensuring a deep understanding of this sustainable technology.

[This article was first published on 4 November 2014.]

I’d like to point out that biogas plants based on dairy manure only, have a bad reputation due to low biogas production per unit mass of manure and therefore a low return on investment. This is made worse by high capital investment and operational costs. In the US viable energy production and waste recycling from anaerobic digestion of manure is only possible if the facility is run on a combination of manure, co-digested with other higher yielding biomass materials.

I see that from looking at this website that you are just one of many people I speak to who interpret the phrase “Climate change is a fact.” to mean “We must all work together to protect the planet.” To do this you are using word “fact” falsely. To say it is a fact is no longer associated with “objective reality” but rather you must be using the word in association with subjective concepts such as “policy.”

Creating your own green energy on the basis of your farm’s manure can put 5p in your pocket for every litre the farm produces. You also get independence from energy producers and distributors and the increasingly rising energy prices.

All I have to say is CRAP.

They could do a better job of collecting carbon so that it can be fed to an Algae Farm, which I believe they could perform better at. Then, using the oil generated by the algae, you can power another generator with it. And use the carbon dioxide to grow vegetables as food. Alternatively, simply refeed it to another batch of Algae.