Attend almost any webinar or conference about anaerobic digestion and the topic of how to increase biogas production will soon be raised. What you will also find is that very often the method offered to raise biogas output efficiency is a new one.

The pace of development of the relatively young biogas industry is remarkably rapid now that so many people and organizations are adopting the technology in the race to fight climate change.

It is not surprising that new tech is popping up.

It is not surprising that new tech is popping up.

Yet it can be that adopting a “hot” new technology results in some early adopters experiencing teething problems. That’s where ultrasound destructors score highly as they have been around for at least 10 years.

Not only have they been tested by time, but in addition, they were at first installed on sewage sludge biogas plants.

How does that make a difference?

It makes a difference because they have been sold under the glare of the professional plant design engineers employed by large water utility companies. You can bet that they will have been well tested, and performance closely monitored in those establishments.

Areas of Use and Advantages

Ultrasound pretreatment of sewage sludge has moved on into new areas of use. The technology is still popular in the wastewater treatment utility industry where the ability of ultrasound to rupture intransigent and tough cell walls. Nowadays, it also has a role in paying dividends for less “hard to digest” feedstocks in agriculture.

In agricultural biogas facilities, ultrasound systems are used to speed up the anaerobic biological decomposition of various biomass materials such as food waste, maize, green waste, slurry, and so on.

As a result, ultrasonic technology is used in a wide variety of AD plant processes.

Ultrasound usually allows for a rise in biogas production with the same amount of substrate or produces the same amount of biogas with less biomass. Plant operators can increase their bottom line, which is biogas plant profitability, in either case.

The equipment needed is compact and is easily installed. It just needs plumbing into the process pipework at a suitable location and connecting to the electricity supply.

There are no mechanical moving parts to go wrong and the maintenance requirements are minimal.

Technical Limits which Slow Down Fermentation – Overcoming these with an Ultrasound Destructor

“High-power ultrasound for the disintegration of biomass.”

Biogas is an organic product made up primarily of methane, which serves as the primary energy carrier. Producing it has a reputation for being expensive, but that does not need to be so.

Removing the technical limits which slow down the fermentation which is necessary for biogas output can have a big effect on raising profitability.

Anaerobic fermentation of organic substrates (biomass) is a refined and well-established technique. Bacteria in the fermenter degrade the biomass at temperatures of roughly 37°C.

However, because the solid biomass is difficult for the bacteria to break down, the biological anaerobic degradation process takes a long time.

Cells with tough cell walls can’t be digested by microbes and without the use of a method of cell destruction, many will pass right through the digestion process.

That’s where these ultrasound devices pay off by smashing up the cells ready for easy digestion. Once the contents of the cells spill out, the methanogens can get to work, making the methane that all biogas plant operators want.

The initial step in the degradation chain is cell lysis (hydrolysis), which incidentally also causes particle or molecule size reduction.

Reduced particle size speeds up the rate of the overall degradation process.

A well-designed ultrasound device's impact relies on its ability to bypass the rate-limiting hydrolysis step. It enables fermentation to occur more rapidly.

Ultrasound oscillations impact not only the structure of the substrates (cell disintegration) but also the active microbes. This occurs through the destructive stimulation of rapidly varying sound pressure waves and cavitation (bubble collapse), prevention of flock formation, and the release of cell enzymes.

Pathogen numbers are reduced through microbe disintegration.

Biological hydrolysis, which can be slow to occur naturally, is consequently aided or completely replaced by the use of ultrasound systems.

The result is quicker and increased cell destruction and more biogas produced sooner.

Intensification of the Fermentation through Ultrasound

“Ultrasound technology – intensification of anaerobic degradation.”

Intensified fermentation takes place on biogas plants with ultrasound. Enzymes (exo-enzymes) are produced by the microorganisms as they ferment the organic substrate.

Even a small energy input promotes an enhanced release of these enzymes, resulting in an increase in the activity of the microorganisms. In sonication, the liquid and solid phases become more mixed, allowing enzymatic attack to take place.

Additionally supplying the plant with more energy causes the plant and bacterial cells to be broken down, which then allows the plant's dissolved organic contents to be released.

The result is a more intense digestion process with even more organic waste being broken down and additional biogas being produced. Since this occurs, then by utilising ultrasound, both more and better quality biogas can be produced from the same biomass feed.

Additionally, less biomass is required when using the same amount of biogas.

Other aspects include an increase in the methane content, as well as a significant improvement in the biogas quality. Because the low-biodegradable agricultural biomasses that are used often yields less than 50% of the methane gas, biogas plants that use conventional biomasses produce less than half of the methane they would produce if using high-biodegradable biomasses.

Additionally, sonication of the volumetric flow has the additional benefit of reducing the viscosity of the fermenter content, which in turn facilitates the increased rate of fluid transfer in the process.

This decreases the power consumption required to run the agitator and pump.

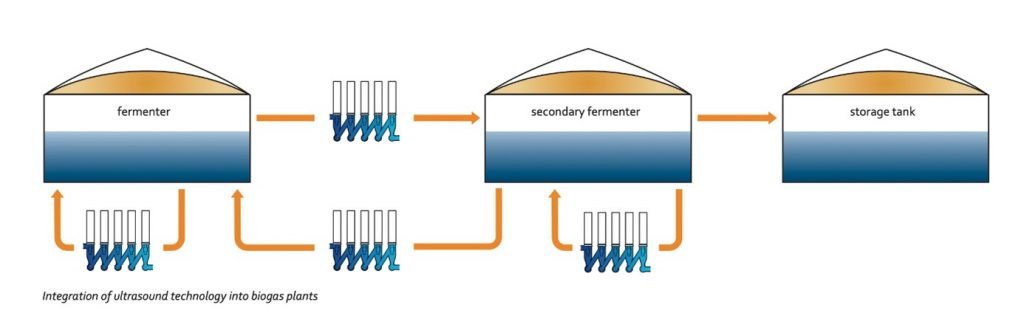

How to Increase Biogas Production – Design and Easy Integration

Modern biogas destructors apply sonification to a recirculated flow from the digester substrate (fermented biomass) to mitigate the more difficult flow characteristics of the raw biomass fed.

To obtain the best results, 30% to 50% of the substrate is added each day. This generally results in an accumulation of 30 to 50% of the substrate amount over time. A standard ultrasound system of the type offered by Ing-Buse, which requires a connected load of 5 kW and has a footprint of 1.45 m x 0.25 m, is very compact

Although inlet and outlet connections are always recommended, providing an electrical and water connection on-site is always advised. You should connect these two devices while they are in use. Ultrasound systems operate around the clock on their own.

While it is always advised to use inlet and outlet connections as well as to provide an electrical and water connection on-site. It is only necessary to provide those two connections while in use. Ultrasound systems themselves are generally in operation around the clock.

How to Increase Biogas Production – The Advantages of Ultrasound Destructors in Summary

- Intensified fermentation provides more biogas from any existing AD system

- More biogas to sell, or upgrade to biomethane, from the same feedstock

- Increased methane content

- Feedstock cost savings if the AD operation buys in the feedstock

- Reduced viscosity can save on digester mixing costs.

For more information on using ultrasound disintegration to increase your biogas production (yield rate) visit the Ing-Buse website.

With these ‘ere ultrasound devices smashing up cells to make ’em easier to digest, does that mean we’re looking at a significant decrease in the overall time it takes for the entire fermentation process, thus potentially making the production of biogas a bit more cost-effective, eh?

And what about the maintenance of these contraptions, are they sturdy enough for long-term use?