Tips for maintaining heat exchangers in anaerobic digestion (AD) plants that use various designs, such as shell and tube heat exchangers and corrugated tube heat exchangers, to heat or cool digester tanks, digester sludge and incoming feedstock to the optimal temperatures needed for microbial activity.

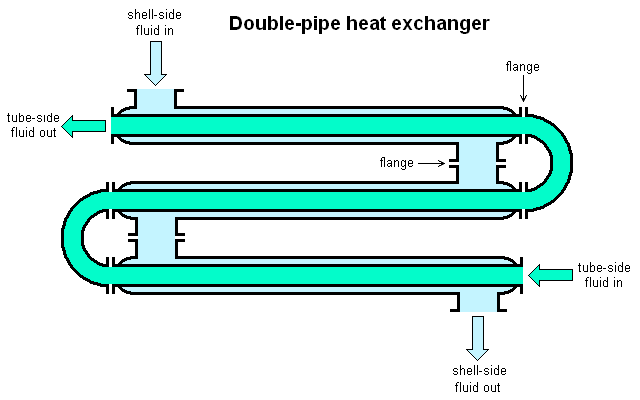

Heat exchangers are used in anaerobic systems, particularly anaerobic digesters, to maintain optimal operating temperatures for microbial activity by transferring heat from hot water to the sewage sludge, manure, food waste, etc.

These exchangers, when well-maintained, maximise the production of biogas and overall process efficiency by effectively transferring heat from sources such as boilers or hot water heated by combined heat and power (CHP) engines to the digester contents.

Key Takeaways for Maintaining Heat Exchangers

- Regular maintenance of heat exchangers in anaerobic systems can extend equipment life by up to 40% while maintaining optimal energy efficiency.

- DIY heat exchanger cleaning is possible with the right tools and safety equipment, potentially saving thousands in professional service calls annually.

- Preventative maintenance schedules based on your specific water quality can prevent system failures that lead to costly biogas production interruptions.

- Chemical descaling and mechanical cleaning are complementary techniques that address different types of fouling common in anaerobic digesters.

- Goodway's specialised descaling solutions are formulated to safely remove buildup without damaging sensitive heat exchanger components in anaerobic systems.

Why Your Anaerobic System's Heat Exchanger Needs Regular Maintenance

Heat exchangers are the lifeline of your anaerobic digestion system. When these critical components become fouled with mineral deposits, biological growth, or debris, your entire operation suffers from decreased heat transfer efficiency and increased operational costs.

A properly maintained heat exchanger can increase methane production by maintaining heat exchangers at optimal digester temperatures, directly impacting your system's energy output and payback period.

The unique environment inside anaerobic digesters creates specialised maintenance challenges. The combination of biological materials, varying pH levels, and constant temperature fluctuations creates the perfect conditions for stubborn buildup that standard maintenance approaches often fail to address.

Left unchecked, this fouling can reduce heat transfer efficiency by up to 50% in just months, dramatically increasing energy consumption while decreasing biogas production.

Developing a consistent maintenance routine isn't just about preventing failure—it's about optimising performance.

Systems with regularly maintained heat exchangers consistently demonstrate 15-25% better thermal efficiency than neglected systems, translating directly to improved biogas yields and reduced operational costs.

This preventative approach also extends equipment lifespan, postponing the substantial capital investment of replacement.

Essential Tools and Safety Equipment for DIY Heat Exchanger Maintenance

Tackling heat exchanger maintenance yourself requires having the right tools on hand before you begin. A comprehensive toolkit ensures you can handle whatever condition you find your heat exchanger in, from light scaling to severe fouling. With proper equipment from Goodway, even challenging maintenance tasks become manageable for the dedicated DIY enthusiast.

Must-Have Tools for Truly Effective Cleaning when Maintaining Heat Exchangers

Start with a quality descaling system that includes a circulation pump capable of moving cleaning solution through your exchanger at the appropriate pressure and flow rate.

For plate-type exchangers common in smaller anaerobic systems, you'll need a set of gasket scrapers, a soft brass brush for stubborn deposits, and plastic putty knives that won't scratch sensitive surfaces.

Tube-type exchangers require specialised tube brushes matching your exchanger's inner diameter measurements and possibly a rotary cleaning system for severe scaling.

Don't overlook the importance of accurate testing equipment. A digital pH meter helps ensure your cleaning solutions are at optimal strength and properly neutralised after cleaning.

Temperature gauges allow you to monitor solution temperatures during the cleaning process, preventing damage to heat exchanger materials. A pressure gauge connected to your circulation system helps identify blockages and monitor cleaning progress.

“Accessible pipework is needed for maintaining heat exchangers for external Digester Heating …” from fluidhandlingpro.com and used with no modifications.

Safety Gear to Protect Yourself

Working with anaerobic systems presents unique hazards that require serious safety precautions.

Chemical-resistant gloves rated for the specific descaling agents you're using provide essential protection against skin exposure and chemical burns.

Full-face shields rather than just safety glasses are necessary when working with pressurised systems or caustic cleaning solutions that could splash or spray.

Respiratory protection becomes critical when opening systems that may release hydrogen sulfide or methane gases. Use a properly fitted respirator with appropriate cartridges rated for these gases.

In confined spaces where anaerobic systems are often located, proper ventilation equipment is non-negotiable, including explosion-proof fans for methane environments.

Never underestimate the importance of proper work attire. Chemical-resistant coveralls protect your clothing and skin from both cleaning chemicals and biological materials present in anaerobic systems.

Steel-toed boots with non-slip, chemical-resistant soles prevent both impact injuries and slips on wet surfaces that are inevitable during maintenance procedures.

Recommended Cleaning Solutions and Chemicals for Use when Maintaining Heat Exchangers

Selecting the appropriate cleaning chemicals for anaerobic system heat exchangers requires understanding the specific type of fouling you're dealing with. Mineral scale from hard water requires different treatment than the protein and biofilm deposits common in digesters.

For calcium carbonate scale (the most common mineral deposit), biodegradable descaling solutions with inhibitors that protect metal surfaces offer the best balance of effectiveness and equipment safety.

Biological fouling from anaerobic processes often requires a two-step approach. An alkaline cleaner first dissolves organic materials and biofilms, followed by an acid-based descaler to remove any underlying mineral deposits.

Always verify compatibility with your heat exchanger materials—stainless steel, copper, and titanium each have different chemical sensitivities that must be respected to prevent damage.

Proper dilution and temperature control maximise cleaning effectiveness while minimising the risk of equipment damage.

Most cleaning chemicals have optimal temperature ranges where they work most efficiently—typically between 120°F and 140°F for descaling solutions. Monitoring and maintaining this temperature throughout the cleaning process can reduce cleaning time and chemical usage by up to 40%.

Step-by-Step Shutdown Procedure Before Heat Exchanger Maintenance

Safety begins with proper shutdown procedures. Before touching any component of your heat exchanger system, implement a methodical shutdown process that prioritises both personal safety and equipment protection.

Document your system's normal operating parameters before shutdown. Record pressure readings, temperature differentials, and flow rates while the system is running properly.

These baseline measurements provide crucial reference points when troubleshooting problems and verifying successful maintenance completion. For additional insights, you can explore the benefits of landfill gas to energy solutions.

1. Proper System Isolation

Begin isolation by closing all valves connecting your heat exchanger to the broader anaerobic system. This includes inlet and outlet valves on both the process side and the heating/cooling medium side.

Valve closure sequence matters—always close outlet valves before inlet valves to prevent pressure buildup within the exchanger that could damage internal components or force contaminants deeper into passages.

Install blind flanges or isolation spades at critical junction points if your system design allows. These physical barriers provide an additional safety layer beyond closed valves, which can leak or be accidentally reopened. For systems without flange connections, consider installing temporary caps or plugs on disconnected lines to prevent accidental discharge of residual fluids.

Verify isolation effectiveness by attempting to drain small amounts of fluid from test ports or drain valves. No fluid flow confirms proper isolation. Take particular care with anaerobic systems where backflow prevention is critical to avoid introducing oxygen into the digester environment, which could disrupt biological processes.

“Digester Heat Exchanger …” from www.biocycle.net and used with no modifications.

2. Pressure Release and Fluid Drainage

Release pressure gradually through designated vent valves, monitoring pressure gauges until they read zero. Never attempt to open any component while under pressure, as trapped gases in anaerobic systems can be both toxic and flammable. Allow sufficient venting time for complete depressurisation, particularly in larger systems where pressure pockets may form.

Drain fluids into appropriate containment vessels suitable for the specific media in your system. Process fluid from anaerobic digesters requires special handling due to biological contaminants and potential methane content.

Position drainage containers below the exchanger to use gravity assistance, and remember that complete drainage may require opening multiple drain points due to the internal geometry of heat exchangers.

Allow adequate time for complete drainage—rushing this step often leads to unexpected fluid releases during disassembly.

For particularly viscous fluids or systems with complex internal geometries, consider introducing compressed air (nitrogen for anaerobic systems to prevent creating explosive conditions) at very low pressure to assist drainage, being careful not to exceed the manufacturer's pressure ratings. For more information, check out these heat exchanger safety precautions.

3. Lockout/Tagout Procedure

Implement formal lockout/tagout procedures on all energy sources connected to the heat exchanger system.

This includes electrical disconnects for pumps and controllers, mechanical locks for steam valves, and securing pneumatic or hydraulic systems. Each energy isolation point should receive its own uniquely keyed lock with a corresponding tag identifying the maintenance technician, date, and expected completion time.

Verify complete energy isolation by attempting to operate the system after lockout. Try starting pumps, opening powered valves, or activating heating elements to confirm all energy sources are truly disconnected.

This verification step prevents dangerous surprises during maintenance and is required by safety regulations in most jurisdictions.

4 Cleaning Techniques That Prevent Heat Exchanger Failure

Effective heat exchanger cleaning requires combining multiple techniques tailored to your specific fouling issues. The right approach depends on both the exchanger design and the nature of the deposits—mineral scaling requires different methods than biological fouling typical in anaerobic systems.

A comprehensive maintenance plan incorporates all these techniques in a strategic sequence for maximum effectiveness.

1. Chemical Descaling Method

Begin by selecting the appropriate chemical solution based on deposit analysis and heat exchanger material compatibility. For anaerobic system exchangers, biodegradable descaling chemicals that break down calcium carbonate without damaging stainless steel or copper components are ideal.

Prepare the cleaning solution at the recommended concentration, typically 5-10% for moderate scaling, using warm water (100-120°F) to enhance effectiveness without risking thermal damage to sensitive components.

Connect your circulation system to the heat exchanger using chemical-resistant hoses, ensuring the pump capacity matches the exchanger's internal volume. Flow direction matters—for initial descaling, circulate against the normal flow direction to help dislodge deposits from their leading edges, which often yields faster results.

Monitor solution pH throughout the process, as rising pH indicates the acid is being neutralised by dissolved scale and may need refreshing to maintain cleaning effectiveness.

Continue circulation until visual inspection of the return solution shows minimal particle content and solution pH stabilises, typically 2-4 hours for moderately scaled systems.

For severely fouled exchangers, multiple chemical treatments may be necessary, with fresh solution introduced after drainage of spent chemicals. Complete the chemical cleaning with a neutralising flush using a mild alkaline solution to prevent residual acid from causing corrosion during system downtime.

2. Mechanical Tube Cleaning

Mechanical cleaning becomes necessary when chemical methods alone can't remove hardened deposits or debris. For tube-type heat exchangers common in larger anaerobic systems, rod-mounted brush systems with diameters precisely matched to the inner tube dimensions provide effective cleaning without damaging tube walls.

Select brush materials based on tube composition—stainless steel tubes require softer nylon or brass brushes, while more durable carbon steel tubes can withstand stiffer stainless steel brushes for stubborn deposits.

Establish a systematic cleaning pattern to ensure complete coverage of all tubes, marking each tube as you progress to prevent missed sections. Insert brushes with steady, controlled pressure, allowing the bristles to do the work rather than forcing the tool, which can damage tube walls or create scoring that becomes future fouling points.

For exceptionally stubborn deposits, rotary tube cleaners that combine mechanical action with simultaneous water flushing offer superior results by immediately removing loosened material.

After mechanical cleaning, flush each tube with clean water to remove dislodged debris before it can resettle elsewhere in the system. Inspect cleaned tubes using a borescope or tube inspection camera to verify cleaning effectiveness and identify any tubes with damage that might require more extensive repair.

This visual verification step prevents the common mistake of reassembling systems with partially cleaned components that will quickly lead to renewed efficiency losses.

“Digester Heating Systems: Heat Exchangers” from www.walker-process.com and used with no modifications.

3. Circulation Cleaning Process

Circulation cleaning combines the chemical action of descaling agents with the physical action of high-velocity fluid movement to enhance deposit removal.

Begin by setting up a closed-loop system using a dedicated cleaning pump capable of generating flow rates 1.5-2 times higher than normal operational flows, which creates turbulence that helps dislodge deposits.

The circulation reservoir should be sized at least 3-4 times the heat exchanger volume to prevent rapid solution saturation with dissolved scale.

Start circulation with clean water to flush loose debris, then introduce cleaning chemicals gradually while the system is running. This approach prevents concentrated chemical contact with any single area that could cause localised corrosion.

Alternate between periods of continuous circulation and pulse cleaning—brief intervals of stopped flow followed by sudden restarts—which creates pressure variations that help crack and dislodge stubborn deposits through mechanical shock.

Monitor solution temperature carefully during circulation cleaning, as chemical reactions with scale often generate heat that can raise solution temperatures to damaging levels.

Many cleaning chemicals become significantly more aggressive at elevated temperatures, potentially damaging gaskets or thin-walled components. Maintain circulation for at least 3-4 hours for moderate fouling, with severe cases potentially requiring 6-8 hours or overnight circulation for complete deposit removal.

4. Flushing and Rinsing Protocol

After chemical and mechanical cleaning, a thorough flushing protocol removes all traces of cleaning agents and loosened debris.

Begin with a clear water rinse at high flow rates for at least 15 minutes, monitoring the discharge until it runs completely clear.

For anaerobic system components where bacterial contamination is a concern, follow with a sanitising rinse using hydrogen peroxide or another compatible biocide that won't leave harmful residues in your system. Learn more about waste management best practices to ensure your system operates efficiently and safely.

Perform neutralisation flushing if acid-based cleaners were used. Circulate a mild alkaline solution (typically sodium bicarbonate) to neutralise any remaining acid and prevent corrosion during system downtime.

Test the final rinse water pH to ensure it matches your system's normal operating range, typically 7.0-8.5 for most anaerobic digesters.

Complete the process with a pressure test using clean water to verify system integrity before reconnection. This final test identifies any leaks or weakened components before hazardous process fluids are reintroduced.

Pressurise to a safe test pressure (often specified to be 1.5 times normal operating pressure, while staying within manufacturer specifications) and maintain for at least 30 minutes, checking all joints, gaskets, and connections for signs of leakage.

“heat from existing CHP …” from www.hrs-heatexchangers.com and used with no modifications.

How to Inspect Your Heat Exchanger for Damage

A thorough inspection during maintenance prevents costly failures and unplanned downtime. Establish a systematic inspection routine that examines every critical component rather than focusing only on obvious problem areas.

Document your findings with photographs and detailed notes that allow you to track deterioration patterns over time and predict when components will require replacement rather than just cleaning.

Timing matters when performing inspections. Examine components immediately after cleaning when deposits have been removed but before reassembly when access is unrestricted.

This timing provides the clearest view of underlying material conditions without the masking effect of operational fouling.

1. Common Wear Points to Check

Focus first on tube-to-tubesheet joints in shell and tube exchangers, as these connection points experience significant thermal stress and are common failure points. Look for signs of tube walking (tubes that have begun to slide out of their seats) or evidence of weeping around tube expansions.

In plate exchangers, carefully examine the seating areas where gaskets contact plates, as erosion in these regions can create leak paths that bypass the gasket seal.

Inspect flow distribution devices like baffles and impingement plates for erosion or displacement. These components direct fluid flow within the exchanger, and their damage can create dead zones or channelling that dramatically reduces efficiency.

Use a flashlight at an angle to highlight erosion patterns that might not be obvious with direct lighting.

Examine inlet and outlet nozzles for signs of localised erosion, particularly in systems handling slurries or particulate-laden fluids common in anaerobic digesters. This erosion often creates a distinctive “horseshoe” pattern downstream of the inlet and can eventually lead to wall perforation if not addressed. Measure wall thickness in these high-risk areas using an ultrasonic thickness gauge to quantify material loss over time.

2. Signs of Corrosion and How to Address Them

Distinguish between different types of corrosion to determine appropriate remediation strategies. Uniform corrosion appears as general surface roughening and material loss, while pitting corrosion creates distinct holes or cavities in the material. The more dangerous stress corrosion cracking appears as fine, branching cracks often visible only under magnification or dye penetrant testing, particularly in areas of high stress like welds or bends.

For stainless steel components common in anaerobic systems, watch for reddish-brown iron oxide deposits that indicate chloride attack and breakdown of the protective passive layer. Address this immediately with proper passivation procedures using citric or nitric acid solutions formulated specifically for stainless steel. For severe corrosion that has created substantial material loss, consult with a metallurgist to determine if repair welding is feasible or if component replacement is necessary.

Document all corrosion findings with measurements and photographs, creating a corrosion map that tracks progression over multiple maintenance cycles. This documentation allows you to calculate corrosion rates and predict remaining useful life for components, enabling proactive replacement scheduling rather than emergency repairs after failure.

3. Testing for Leaks and Cracks

Implement a staged leak testing approach beginning with visual inspection under good lighting, followed by more sophisticated methods for suspect areas. Use dye penetrant testing on accessible external surfaces to reveal microscopic cracks invisible to the naked eye. The bright red or fluorescent dye wicks into surface-breaking cracks and provides a clear visual indication of defects as small as 0.001 inches wide. To understand more about the decomposition process and its impact, check out what happens to rubbish in a landfill.

For tube-type heat exchangers, perform hydrostatic testing by blocking one end of each tube bank and filling from the opposite end. Pressurise to test pressure and observe for water seepage. For more sensitive detection, use pressure decay testing where the system is pressurised with air or nitrogen and isolated, then monitored for pressure drops that indicate leakage too small to produce visible water seepage.

In plate heat exchangers, interleaved pressure testing detects cross-contamination between the two fluid circuits. Pressurise one side of the plate pack while leaving the other open to the atmosphere, then check for fluid emergence from the unpressurized side. This identifies gasket failures or plate cracks that could allow process contamination during normal operation.

Reassembly Best Practices That Extend Equipment Life

Reassembly is not simply the reverse of disassembly—it requires precision and attention to detail that directly impacts equipment longevity. Begin by creating a clean workspace free of dirt and debris that could contaminate sealing surfaces. Thoroughly clean and inspect all components before reassembly, including those parts you didn't disassemble, as they may have been exposed to cleaning chemicals or debris during the maintenance process.

Take advantage of the maintenance opportunity to replace all gaskets and sealing components rather than reusing old ones, even if they appear undamaged. The minimal cost of new gaskets is insignificant compared to the potential consequences of leakage. For anaerobic systems, select gasket materials specifically rated for the unique combination of biological exposure, chemical compatibility, and temperature range your system experiences. Additionally, understanding the utilisation benefits of landfill gas to energy solutions can provide insights into optimising your system's performance.

Proper Sealing Techniques

Prepare sealing surfaces by removing all traces of old gasket material using non-metallic scrapers that won't damage the seating surfaces. Inspect these surfaces under strong light at a low angle to highlight any nicks, scratches, or distortions that could prevent proper sealing. Minor imperfections in metal surfaces can often be remediated using fine wet/dry sandpaper (600 grit or finer) on a flat block, working in a crosshatch pattern to maintain surface flatness.

Apply appropriate gasket compounds sparingly, using only products compatible with your process fluids and temperature range. For anaerobic systems, select compounds that maintain integrity in biological environments and won't contribute to microbial growth. Place gaskets carefully without stretching or compressing them during positioning, which can create stress points that fail prematurely under pressure.

For spiral-wound gaskets or metal-jacketed designs used in higher-pressure applications, ensure the gasket is properly centred before any bolts are tightened. Off-centre gaskets can extrude under pressure or fail to seal properly. Use alignment dowels or temporary alignment pins to maintain precise positioning throughout the assembly process.

Correct Bolt Torque Sequence

Follow a specific cross-pattern tightening sequence that gradually and evenly compresses the gasket without distorting the flanges. Begin with hand-tightening all bolts to ensure proper component alignment, then implement a three-stage torque process: first to approximately 30% of final torque, then 60%, and finally 100%. This gradual approach allows the gasket material to flow and seat properly, preventing localised over-compression that can lead to premature failure. For more information on maintaining heat exchangers, you can visit HRS Heat Exchangers.

Use calibrated torque wrenches rather than relying on feel or experience, and record the applied torque values in your maintenance documentation. Different gasket materials require specific compression forces, so consult manufacturer's specifications for your particular components. For critical joints or high-pressure systems, consider using ultrasonic bolt tension monitors that measure actual bolt stretch rather than applied torque, which provides more accurate loading data. For more on maintaining heat exchangers in high-pressure systems, explore landfill gas to energy solutions and their benefits.

After initial torque application, allow the assembly to stand for 12-24 hours, then perform a final torque check. Gasket relaxation and settling can reduce effective bolt tension by as much as 20% in the first day after assembly. This retightening step is particularly important for non-metallic gaskets common in anaerobic systems, which typically exhibit higher relaxation rates than metal gaskets.

Monthly Maintenance Checklist for Peak Performance

Visual Inspection Points

Develop a routine monthly inspection that focuses on early warning signs of developing problems. Check for any external signs of leakage, particularly around gasketed joints, sight glasses, and instrument connections. Even minor weeping indicates seal degradation that will likely worsen over time. Inspect insulation for damage or dampness that might indicate hidden leakage beneath.

Examine external surfaces for discolouration or staining that could indicate internal fluid leakage or external corrosion beneath insulation. Pay special attention to support structures and mounting brackets, which often corrode faster than the exchanger itself due to dissimilar metal contact or trapped moisture. Look for any signs of component movement or vibration damage, such as fretting on mounting surfaces or loosened fasteners.

Document inspection findings with dated photographs that provide visual references for comparison in subsequent months. This visual history often reveals slowly developing problems that might otherwise go unnoticed, such as progressive staining patterns that indicate small but worsening leaks, or gradual displacement of components due to thermal cycling or vibration.

Temperature and Pressure Monitoring

Implement a formal temperature and pressure logging program at standardised operating conditions to track performance trends over time. Record inlet and outlet temperatures for both sides of the exchanger, along with corresponding flow rates when possible. Calculate and track the temperature approach (the smallest temperature difference between the two fluids) and the temperature range (the change in temperature of each fluid) as key performance indicators. For more information on how these practices contribute to waste management best practices, consider exploring additional resources.

Monitor pressure drop across each side of the exchanger as the most sensitive early indicator of internal fouling. Increasing pressure differential with constant flow indicates progressive restriction from scale buildup or debris accumulation. Establish trigger points for maintenance intervention based on percentage increase from baseline pressure drop—typically 15-20% increase warrants investigation, while 30% or greater increase signals the need for immediate cleaning.

For systems with digital controls, implement automated trend logging and alert functionality that notifies operators when parameters drift beyond established thresholds. This automation catches gradual performance degradation that might go unnoticed in manual monitoring systems and provides documentation of system performance over time for maintenance planning.

Descaling Schedule Based on Water Hardness

Customise your maintenance intervals based on water quality data specific to your facility. Systems using hard water (>180 ppm calcium carbonate) may require quarterly descaling, while those with moderately hard water (120-180 ppm) might extend to semi-annual cleaning. Systems using treated water with <60 ppm hardness may operate effectively with annual descaling maintenance.

Consider seasonal variations in water quality, particularly for systems using well water or surface water sources that can experience significant hardness fluctuations throughout the year. Increase monitoring frequency during periods of known higher mineral content, and adjust cleaning schedules accordingly. In agricultural regions, be particularly vigilant during fertiliser application seasons when runoff can dramatically alter water chemistry.

Implement water treatment protocols appropriate to your water hardness levels to extend intervals between major cleaning operations. Even simple treatments like side-stream filtration or magnetic water conditioners can significantly reduce scale formation rates in moderately hard water systems. For severe hardness issues, consider permanent installation of chemical injection systems that continuously dose scale inhibitors proportional to flow rate.

Troubleshooting Common Heat Exchanger Problems

Systematic troubleshooting saves time and prevents misdiagnosis of complex heat exchanger problems. Begin by gathering operational data, including temperatures, pressures, and flow rates from both sides of the exchanger, and comparing current values against baseline performance metrics. This comparison often immediately highlights which fluid circuit is experiencing problems and narrows the investigation scope.

Document the troubleshooting process methodically, testing one variable at a time and recording results before moving to the next potential cause. This disciplined approach prevents the common error of making multiple simultaneous changes that obscure cause-and-effect relationships and can lead to incorrect conclusions about the underlying problem.

1. Reduced Heat Transfer Efficiency

When heat transfer performance drops while flow and temperature conditions remain constant, internal fouling is the most likely culprit. Distinguish between different fouling mechanisms by analysing the pattern of performance decline—gradual deterioration over months typically indicates mineral scaling, while rapid efficiency drops often point to biological fouling or debris accumulation. Compare the temperature profiles and pressure drops of both circuits to identify which side is fouled, as cleaning methods differ significantly between process-side and utility-side fouling.

Consider less obvious causes if cleaning doesn't resolve efficiency issues. Air or gas binding within the exchanger creates insulating pockets that dramatically reduce heat transfer. This condition often develops gradually as dissolved gases come out of solution during heating or pressure reduction. Vent the system completely during operation, and consider installing automatic air eliminators at high points if the problem recurs.

Check for improper fluid distribution causing channelling or bypassing within the exchanger. In plate units, this often results from gasket damage or plate misalignment, while in shell-and-tube designs, damaged baffles or tube blockages create preferential flow paths that reduce the effective heat transfer surface. Thermal imaging of the exterior can often reveal these flow distribution problems as uneven surface temperature patterns during operation.

2. Pressure Drop Issues

Excessive pressure drop almost always indicates some form of flow restriction, but the specific cause requires careful investigation. Graph pressure drop against flow rate on logarithmic scales—restrictions from particulate fouling typically show greater-than-square-law relationships (where doubling flow more than quadruples pressure drop), helping distinguish this condition from normal flow resistance. Sudden pressure drop increases often indicate dislodged material partially blocking flow passages or damaged internal components restricting flow.

Insufficient pressure drop presents the opposite problem and typically indicates internal bypassing. In plate exchangers, check for damaged or improperly installed gaskets that allow fluid to bypass the heat transfer surfaces. For shell-and-tube units, inspect tube-to-tubesheet joints and internal baffle sealing areas where erosion or corrosion can create unintended flow paths that reduce residence time and heat transfer effectiveness.

Don't overlook external causes of pressure anomalies. Partially closed isolation valves, clogged strainers upstream of the exchanger, or incorrect pump operation can all create pressure issues that mimic internal exchanger problems. Verify the condition of all auxiliary components in the flow path before disassembling the heat exchanger itself.

3. Fluid Leakage Solutions

Address external leakage immediately, as even minor weeping indicates seal failure that will likely worsen rapidly under pressure and thermal cycling. For gasketed plate exchangers, uneven gasket compression is a common cause—check for proper torque on all tightening bolts and look for frame distortion that prevents uniform loading. Thermal cycling often requires more frequent retorquing than manufacturers suggest, particularly in systems with large temperature swings.

Internal leakage between fluid circuits presents a more serious problem, particularly in anaerobic systems, where cross-contamination can introduce oxygen into the anaerobic environment. Pressure testing with the primary circuit pressurised and the secondary circuit open can identify the leak location. In plate units, dye testing helps pinpoint the specific plate with through-wall cracking or gasket failure, allowing targeted replacement rather than complete regasketing.

For welded or brazed units without replaceable gaskets, specialised epoxy compounds designed for high-temperature, chemical-resistant applications can provide temporary sealing of external leaks until replacement components arrive. However, these should never be considered permanent repairs for internal leakage where cross-contamination is possible. Document all leak repairs in detail, as leakage patterns often provide valuable information about system design flaws or operational stresses that need addressing to prevent recurrence.

4. Biofilm Growth Prevention

Anaerobic systems are particularly prone to biofilm formation that can significantly impair heat transfer and accelerate corrosion. Implement regular clean-in-place procedures using appropriate biocides compatible with your system materials. Quaternary ammonium compounds often provide effective biofilm control without harming stainless steel components common in heat exchangers. Alternate between different biocide classes to prevent the development of resistant organisms. For more insights into sustainable practices, explore landfill gas to energy solutions.

Design your operational protocols to minimise conditions that promote biofilm growth. Avoid prolonged periods of stagnation or low-flow conditions that allow microorganisms to attach and colonise surfaces. For systems that must operate intermittently, implement automated flush cycles with treatment chemicals during shutdown periods to discourage biological growth during idle times.

When DIY Won't Cut It: Signs You Need Professional Help

While most maintenance can be handled in-house with proper training and equipment, certain situations demand professional intervention. Recognize these scenarios early to prevent turning a manageable issue into a catastrophic failure. Changes in heat exchanger performance that don't correspond to known fouling patterns may indicate internal mechanical damage that requires specialized expertise to diagnose and repair.

Evidence of metal fatigue, stress cracking, or significant corrosion damage typically requires professional assessment. These conditions compromise the structural integrity of pressure-containing components and create potential safety hazards. An experienced heat exchanger specialist can evaluate whether repair is possible or if replacement is necessary.

- Unexplained vibration or noise during operation that wasn't previously present

- Persistent leakage that returns despite proper gasket replacement and torquing procedures

- Evidence of tube vibration or fretting in shell-and-tube designs

- Pressure vessel damage, including dents, bulges, or distortions

- Significant localised corrosion or erosion exceeding 20% of the original wall thickness

Don't hesitate to consult with the original equipment manufacturer or a qualified heat exchanger specialist when these conditions arise. The cost of professional consultation is minimal compared to the expense and hazard of catastrophic equipment failure, particularly in anaerobic systems where containment breaches can create both biological hazards and explosive conditions from released methane.

Maximise Your Anaerobic System's Efficiency With These Maintenance Tips

Implementing a comprehensive maintenance program for your heat exchangers isn't just about preventing failures—it's about optimising your entire anaerobic system's performance. Well-maintained heat exchangers operate closer to design specifications, maintaining heat exchangers' optimal temperatures for biological processes that maximise methane production. This efficiency directly impacts your return on investment and operating costs by reducing energy consumption while increasing biogas yield.

Create a unified maintenance calendar that coordinates heat exchanger servicing with other anaerobic system components to minimise operational disruptions. Schedule major cleaning operations during planned digester maintenance periods when possible, and use these opportunities to comprehensively evaluate all system components rather than focusing on isolated equipment servicing.

Frequently Asked Questions – Maintaining Heat Exchangers

Based on my experience helping anaerobic system operators maintain their equipment, these are the most common questions that arise during maintenance planning and implementation.

Understanding these fundamentals will help you develop a maintenance program tailored to your specific system configuration and operating conditions.

- How does fouling impact anaerobic digester performance beyond just heat transfer?

- What's the most effective way to track heat exchanger performance degradation over time?

- Are there specialised cleaning chemicals designed specifically for anaerobic system fouling?

- How do I balance thorough cleaning against the risk of damaging sensitive components?

- What documentation should I maintain for regulatory compliance related to heat exchanger maintenance?

How often should I clean my heat exchanger in an anaerobic system?

Cleaning frequency depends primarily on three factors: water quality, operating temperature, and biological loading. Systems operating with hard water typically require cleaning every 3-6 months, while those with water treatment systems might extend to annual cleaning. However, in anaerobic systems, biological fouling often becomes the limiting factor rather than mineral scaling.

Monitor pressure differential across the exchanger weekly—when it increases 15-20% above baseline, schedule cleaning within the next 30 days. Increases exceeding 30% warrant immediate intervention regardless of the regular maintenance schedule. For more insights into energy recovery, explore generating electricity from waste systems.

Consider implementing a predictive maintenance approach using temperature differential monitoring alongside pressure readings. As fouling develops, the temperature approach between the two fluids widens as heat transfer efficiency decreases.

By graphing these values over time, you can project when cleaning will become necessary and schedule the work of maintaining heat exchangers during convenient operational windows rather than reacting to performance problems.

What chemicals are safe to use when cleaning a heat exchanger?

Safety considerations for cleaning chemicals include compatibility with heat exchanger materials, operator exposure risks, and the environmental impact of disposal.

For stainless steel components common in anaerobic systems, phosphoric acid-based descalers offer excellent mineral deposit removal with minimal corrosion risk when used at the proper concentration and temperature. These formulations, for maintaining heat exchangers, typically include corrosion inhibitors specifically designed to protect stainless alloys while dissolving calcium carbonate scale.

For biological fouling common in anaerobic systems, a two-step approach works best: first, an alkaline cleaner with surfactants to remove organic materials and biofilms, followed by an acid descaler for any underlying mineral deposits.

Always verify chemical compatibility with gasket materials as well as metal components—EPDM and Viton gaskets have different chemical resistance profiles, and using incompatible cleaners can cause gasket swelling or deterioration that leads to leaks upon reassembly.

Goodway's specialized descaling solutions are formulated specifically for these applications, ensuring effective cleaning without component damage.

Can I clean a heat exchanger without taking it apart?

Clean-in-place (CIP) procedures offer effective maintenance without disassembly for many heat exchanger designs, saving significant labour and downtime.

The key to successful CIP is proper flow rate and chemistry—circulation rates should be 1.5 to 2 times normal operating flow to create turbulence that enhances cleaning effectiveness.

Use specialised CIP equipment for maintaining heat exchangers, with reversible flow capability to attack deposits from both directions, which significantly improves the removal of asymmetric fouling that typically builds up on the leading edges of heat transfer surfaces.

How do I know if my heat exchanger needs replacement instead of cleaning?

Replacement becomes necessary when cleaning no longer restores performance or when structural integrity is compromised. Key indicators include: returning to baseline performance requires increasingly frequent cleaning cycles; pressure testing reveals persistent leaks despite gasket replacement; wall thickness measurements show corrosion or erosion exceeding 40% of the original specification; or visible cracking appears in pressure-containing components.

Economic factors also influence this decision—when the annual cost of maintenance (including labour, chemicals, and downtime) exceeds 15-20% of replacement cost, upgrading to a new unit often provides better return on investment.

While maintaining heat exchangers, consider replacement with more fouling-resistant designs when chronic maintenance issues occur.

Modern wide-gap plate heat exchangers or self-cleaning spiral designs can dramatically reduce maintenance requirements in heavily fouling anaerobic applications. Reportedly, they often pay for themselves within 1-2 years through reduced maintenance costs and improved thermal performance. For more insights on waste management practices, explore our best practices guide.

What's the difference between maintaining heat exchangers in aerobic vs. anaerobic systems?

Anaerobic systems present unique maintenance challenges compared to their aerobic counterparts. The absence of oxygen creates reducing conditions that favour different corrosion mechanisms and microbial communities. Sulfide stress cracking becomes a significant concern in stainless components exposed to hydrogen sulfide common in anaerobic environments. This necessitates more frequent inspection of welds and high-stress areas during heat exchanger maintenance activities.

The biological fouling in anaerobic systems contains different microbial communities that form more tenacious biofilms, often with embedded mineral components that resist single-chemistry cleaning approaches.

For the most reliable performance from your anaerobic system's heat exchangers, develop a maintenance program that addresses these unique challenges with appropriate frequency, cleaning chemistry, and inspection protocols. The investment in proper maintenance yields returns through improved system efficiency, extended equipment life, and prevention of costly emergency repairs or unplanned downtime.