There are many types of biogas plants. The first step to selecting the best one for your project is to understand what types are available. Read this article and watch our video. This is essential training for those seeking to find the best AD Plant Design for their needs.

Types of Biogas Plants Most Popular in the US

In the US biogas production has never been given any significant financial incentives. US anaerobic digestion facilities are, as a result, a good place to look to find what types are popular because their AD plant selection is based purely on what makes money. There is no danger of distortion of the US AD plant market by government subsidies.

Anaerobic digestion has historically been limited to agricultural biogas plants and wastewater treatment of sewage sludges. Recently, a number of US colleges have built their biogas plants to take food waste from their own kitchens and resident communities.

Food waste digestion is an obvious area for development in the US. But, so far the biggest sector in terms of numbers of biogas plants is the agricultural sector. Within that large dairy farms predominate. That's due to the efficiencies which come from the economy of scale.

The place to find information on those is the US Department of Agriculture (USDA) Agstar website. The following video and subsequent text are based upon information on their website:

5 Types of Biogas Plant – The Most Common US AD Plant Designs

Keep watching for our top 5 anaerobic digestion plant design types, listed in order of popularity in the USA.

Type 1. Covered Anaerobic Lagoon

In a covered anaerobic lagoon design, methane is recovered and piped to the combustion device from a lagoon with a flexible cover.

Here is a diagram of a covered anaerobic lagoon showing 2 cells.

The first cell collects the digester influent and traps the biogas and the second cell collects the digester effluent.

Some systems use a single cell for combined digestion and storage.

Not as sophisticated as CSTR tank systems, they have a plastic membrane cover with the primary purpose of treating manure. Most are seen on large US dairy farms. These lagoons are hard to clean out when sand and silt build up in the bottom.

Type 2. Plug Flow Digester

Plug flow digesters are primarily used at dairy operations that collect manure by scraping.

Mixed plug flow systems have been used in a wider variety of operations because they can tolerate a broader range of solids concentrations.

Here is a diagram of a plug flow digester showing digester influent entering and flowing through the digester, with the biogas being captured and stored beneath a cover.

This example shows a plug flow digester with a flexible plastic membrane cover.

This example shows a plug flow digester with a rigid cover.

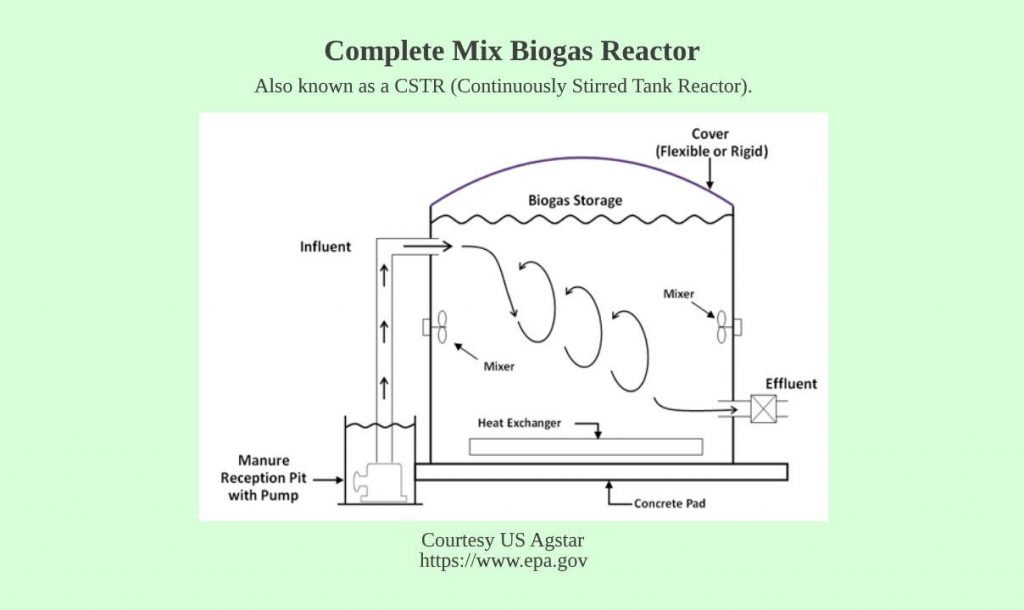

Type 3. Complete Mix Biogas Plant

These are also called CSRs or Continuously Stirred Reactors.

Completely mixed digesters are designed with an enclosed, heated tank with a mechanical, hydraulic or gas mixing system.

Complete mix digesters work best when there is some dilution of the excreted manure with water (e.g., milking centre wastewater).

Here is a diagram of a complete mix digester illustrating the process of adding manure into the digester; mixing, heating and storing the biogas within the digester; and extracting the resulting effluent.

Here is a photo of two complete mix digester tanks.

Here is another photo of an externally mounted mixer.

They are usually fed by agricultural waste, often augmented with some purpose-grown crops. They are also used as food waste digesters. Globally there are thousands of this type of biogas plant.

Other common designs for anaerobic digesters include:

Type 4. Batch Digesters

A batch digester is the simplest form of digestion, where manure is added to the reactor at the beginning of the process as a batch. The reactor is filled and the reactor remains closed for the duration of the process.

A batch digester is the simplest form of digestion, where manure is added to the reactor at the beginning of the process as a batch. The reactor is filled and the reactor remains closed for the duration of the process.

This type of digester is unsuitable for liquid biomass types and is usually used for creating biogas (methane) from the organic fraction of household waste. It is also suitable for green garden waste.

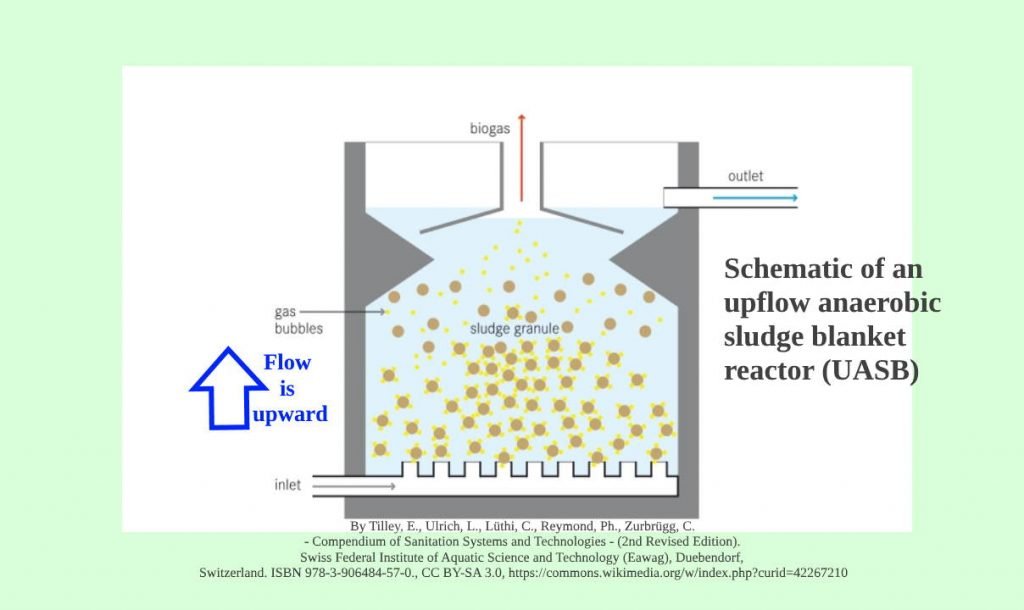

Type 5. Induced Blanket Reactors

These are also known as USBRs (Upflow Anaerobic Sludge Blanket Reactors).

These are digesters in which a blanket of sludge develops and retains anaerobic bacteria, providing a bacteria-rich environment through which the feedstock must pass.

A digester type which has been in use in industry for more than 50 years, primarily used for treating organically contaminated water, with added biogas production. To use this method instead of aeration requires a much larger tank than if done aerobically. Therefore, the initial construction cost is higher. The methane in the biogas needs to be highly valued to make these plants economic.

Source: US Agstar Website: www.epa.gov/agstar

Types of Biogas Plants – Conclusion

The process of anaerobic digestion is made use of to handle waste, to create eco-friendly biogas, and also generate all-natural plant food with extremely reduced or zero-carbon exhausts.

An anaerobic digester, necessarily, is merely the container and the technology used varies, as shown here.

Ancillaries such as mixing are important, especially the mixing in which anaerobic food digestion takes place.

Whatever type of biogas process is chosen it's the all-natural procedure, which makes it very green and sustainable which is most important. A procedure whereby microbes rot down biomass and make eco-friendly products.

Products like biogas provide renewable energy which when burnt, helps reduce carbon emissions.

Biogas production is already helping to reduce the effect of increasing greenhouse gases in our atmosphere. However, it can only be made within the “lack-of-oxygen” reactor vessels such as the types described here.

All those planning to build a biogas plant should consider carefully the choice of biogas plant type as outlined here.

________________

This presentation contains images that are used under a Creative Commons License.

Can you ever see the day when there will be just one biogas plant model for all uses? That is what people want.

After going over a number of the blog posts on your site, I truly appreciate your way of blogging. I saved it to my bookmark list. Is the tubular biogas system the cheapest? I think it is the easiest to set-up. How long do they last though?

My Local Authority has recently issued a tender for the treatment of doorstep collected biodegradable organic waste and they intend to collect our food waste separately from green waste. They say that using their proposed source segregated approach to food waste collection means that Anaerobic Digestion is the best waste treatment available. Is it really? And, won’t the place smell?