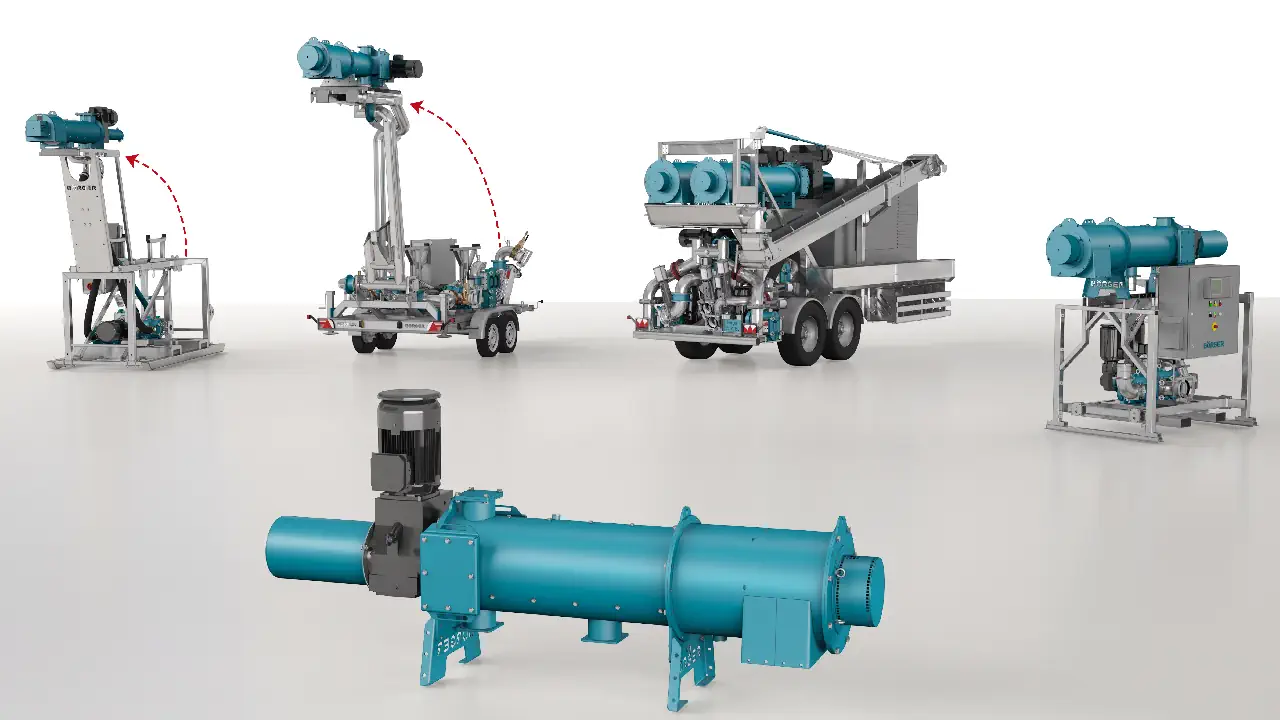

A small-scale digestate separator has been added to the popular Börger Bioselect™ range of digestate separator units. This adds to their range which has become a top choice for operators seeking solid/ liquid digestate separation. Virtually all AD plant operators would be assisted by this technology at the outlets from their biogas reactors.

Press Release 23 January:

New Small-scale Separator is Big on results

Following the success of its acclaimed Separators since their launch in 2016, Borger has released a new, affordable, 25 m³/h model, suitable for dairy farmers with herds of up to 150 – and for small-scale biogas operators.

The launch of this compact new Bioselect RC 25 (which complements Borger’s existing range of up to 40 m³/h, 75 m³/h and 150 m³/h Separators), provides easy and highly effective separation of slurry.

Reducing storage volume and creating effective fertilization with the liquid phase or use of solids as bedding material, the Borger Separator can be fully installed or used as a mobile unit, consistently achieving Dry Solids (DS) content up to 38%.

The Borger Bioselect small-scale digestate separator 25 m³/h model also benefits from a new feature that enables the user to adjust the length of the dewatering chamber to their specific requirements for enhanced separation efficiency.

To ensure optimal utilization of the Separator, as well as long service life, Borger manufactures ready-to-connect, complete units with Separator, Borger rotary lobe pump and control unit that synchronizes the operation of the components. Upon request, Borger can also take care of the construction of the frame or the trailer.

In addition, Borger has developed a new frame concept for its separators – customized, using a modular principle depending on the amount of space available at the customers’ premises. For the new Bioselect RC 25, the frame can be equipped with a three-point-hitch frame. This makes it possible to relocate the entire unit easily and quickly by using a tractor.

In addition, Borger has developed a new frame concept for its separators – customized, using a modular principle depending on the amount of space available at the customers’ premises. For the new Bioselect RC 25, the frame can be equipped with a three-point-hitch frame. This makes it possible to relocate the entire unit easily and quickly by using a tractor.

Borger UK

01902 798977

Bioselect™ is the separation technology brand which is produced by pump specialist Börger pumps. It's a purely mechanical process, liquid parts are separated from solid parts in the slurry (solid and liquid mixture).