We saw that a question being asked on the forums is, “What is the difference between biogas and landfill gas?”, so we thought that we would write this article to explain.

Read on to find out the differences of biogas versus landfill gas, and you will appreciate that people tend to call landfill gas “biogas”. But despite the source process of anaerobic digestion being the same for both, there are additional impurities in landfill gas:

Definitions of Biogas and Landfill Gas

Biogas is the raw, unfiltered and unpurified methane gas from the anaerobic digestion process. It is the gas from biogas plants, ranging from home-sized units to those huge biogas reactors you see on farms.

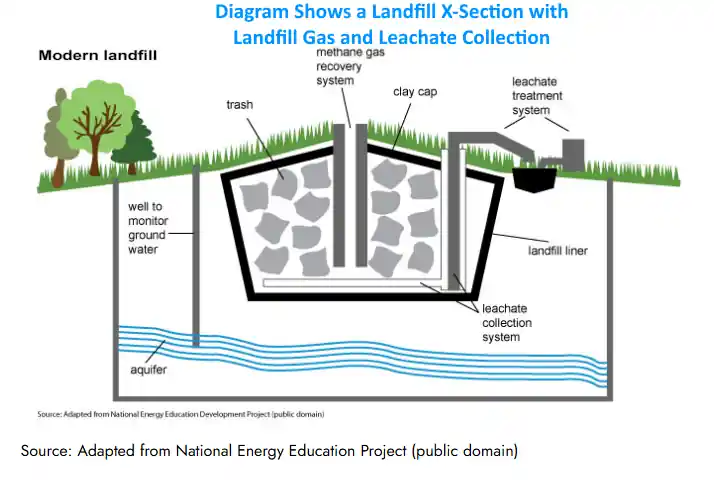

Landfill Gas is simply the raw high-methane-content gas which modern, rapidly filled and well-compacted landfills produce.

The Similarities Between Biogas and Landfill Gas

Biogas and landfill gas are essentially created by the same process, the anaerobic digestion process, so they are very much the same in their basic composition and calorific value when burnt.

The Differences Between Biogas and Landfill Gas

However, there is a difference between biogas and landfill gas, which becomes very important when these gases are used as an energy source, and burnt or processed to purify the methane into pure CH4. The difference is that landfill gas has many more “trace” impurities than AD plant-produced biogas.

Biogas made from an anaerobic digestion plant, which is fed by pure organic biomass, won’t normally possess the many “trace” (small %age quantities) chemicals that are invariably found in any landfill gas.

However, anaerobic digestion plant biogas may include trace impurities derived from the feedstock contents. For this reason, it is always worth obtaining a lab test analysis of the trace compounds found before burning it in a gas engine to generate power, or before sending that gas to be purified in a biogas to biomethane purification system.

Taking that step at an early stage of any biogas project, particularly for a landfill-gas biogas, could have very large benefits later from anticipating the costs and downtime associated with landfill gas engine maintenance.

Probably the best known, and very troublesome, trace organic compound in landfill gas is siloxane. Siloxane causes damage to reciprocating gas engines, because it forms a hard deposit within the engines. This persists and will eventually cause a failure of the generating equipment, unless it is either removed by purification before the gas enters the engine, or gas engines are regularly stripped down and cleaned.

We found more information on biogas in the following quotation, which may help readers understand biogas in more detail:

“Biogas typically refers to a mixture of different gases produced by the breakdown of organic matter in the absence of oxygen. Biogas can be produced from raw materials such as agricultural waste, manure, municipal waste, plant material, sewage, green waste or food waste. Biogas is a renewable energy source and in many cases exerts a very small carbon footprint.

Biogas can be compressed, the same way natural gas is compressed to CNG, and used to power motor vehicles. In the UK, for example, biogas is estimated to have the potential to replace around 17% of vehicle fuel. It qualifies for renewable energy subsidies in some parts of the world. Biogas can be cleaned and upgraded to natural gas standards, when it becomes bio-methane. Biogas is [classed] as a renewable resource, because its production-and-use cycle is continuous, and it generates no net carbon dioxide. Organic material grows, is converted and used and then regrows in a continually repeating cycle. From a carbon perspective, as much carbon dioxide is absorbed from the atmosphere in the growth of the primary bio-resource as is released when the material is ultimately converted to energy.” Via biogas_composition.html

Frequently Asked Questions (FAQs) About Biogas and Landfill Gas

General Overview of the Difference Between Biogas and Landfill Gas

What is Biogas?

Biogas is a mixture of gases, primarily methane (CH4 and carbon dioxide (CO2), produced by the anaerobic digestion of organic matter. Common feedstocks include agricultural waste, manure, municipal waste, sewage, green waste, and food waste. It is considered a renewable energy source due to its continuous production cycle and low carbon footprint.

What is Landfill Gas?

Landfill gas is the gas generated by anaerobic decomposition of organic matter in landfills. It contains a high percentage of methane, along with CO2 and trace impurities, resulting from the mixed nature of landfill materials.

Composition and Characteristics

How are Biogas and Landfill Gas Similar?

- Both are generated via the anaerobic digestion process.

- Both contain methane and carbon dioxide as major components.

- Both have similar calorific values when combusted.

What Are the Key Differences Between Biogas and Landfill Gas?

- Source Material: Biogas is produced from controlled organic feedstocks, while landfill gas arises from mixed, often contaminated, landfill contents.

- Impurities: Landfill gas contains more trace impurities, such as siloxanes and volatile organic compounds (VOCs), which are less prevalent in biogas produced from pure organic materials.

- Application Challenges: The impurities in landfill gas require additional purification and maintenance of gas engines to prevent equipment damage.

Applications and Purification

How is Biogas Used?

- Energy Generation: Used in gas engines to generate electricity and heat.

- Transportation Fuel: When upgraded to biomethane, biogas can replace natural gas as vehicle fuel.

- Subsidies: Biogas often qualifies for renewable energy incentives worldwide.

How is Landfill Gas Used?

- Landfill gas is primarily used for power generation after purification to remove harmful impurities.

What is Biomethane?

Biomethane is purified biogas that meets natural gas standards. It can be compressed for use in vehicles or injected into natural gas pipelines.

Technical Concerns and Solutions

What are the Common Impurities in Landfill Gas?

- Siloxanes

- Volatile Organic Compounds (VOCs)

- Trace organic compounds

Why is Siloxane a Problem in Gas Engines?

Siloxane deposits form hard residues during combustion, leading to engine damage and eventual failure. Preventative maintenance or purification is essential.

Is Purification Always Necessary for Biogas?

Yes, particularly if the gas will be used in sensitive equipment like gas engines or upgraded to biomethane. A lab analysis of trace compounds is recommended to anticipate potential costs and maintenance needs.

Environmental Benefits and Sustainability

Why is Biogas Considered a Renewable Energy Source?

- Biogas production is part of a closed carbon cycle, where the carbon dioxide released during energy generation is offset by the carbon absorbed during the growth of organic feedstocks.

What is the Carbon Footprint of Landfill Gas Compared to Biogas?

While both have renewable aspects, landfill gas often requires more energy for purification, and its mixed-source origin may introduce contaminants that increase its environmental impact.

Practical Tips

How Can Trace Compounds in Gas Be Managed?

- Perform early-stage lab tests to identify impurities.

- Invest in purification systems tailored to the specific gas composition.

- Schedule regular maintenance for gas engines to prevent siloxane-related failures.

What Should Be Considered for a New Biogas Project?

- Source and composition of feedstock

- End-use requirements (e.g., electricity, biomethane, or direct combustion)

- Long-term maintenance and purification needs

- Regulatory incentives and subsidies available in your region

[First published 11 November 2016.]