Introduction to Biogas Upgrading Technologies

The science of the existing biogas upgrading technologies is very young and rapidly evolving. In this article, we first provide our video as a rapid introduction to this subject.

If you watch our video which is an introduction to the content of this page, don't forget to scroll on down afterwards for much more information:

This presentation contains images that were used under a Creative Commons License. Click here to see the full list of images and attributions goto: https://link.attribute.to/cc/365367

The primary function of biogas upgrading involves removing CO2 to improve gas quality by increasing the volumetric energy content. Biogas upgrading is necessary for natural gas pipeline injection and vehicle fuel applications.

In this text, we concentrate on CO2 removal as the most important part of any biogas upgrading undertaking.

The most widely commercialised and used upgrading technologies are those that have for a long time been employed by the natural gas industry, pressure swing adsorption (PSA), chemical solvent scrubbing (using amines), and pressurised water scrubbing.

Newer technologies have recently broken into the market by improving efficiencies, lowering costs, or decreasing the footprint including physical solvent scrubbing (using glycols), membrane separation, and cryogenic distillation.

There are also a number of emerging gas upgrading technologies in the research and pilot phase that claim lower operating costs. In addition, simpler and more compact process designs are in our list, and we have described them later (e.g., rotary water scrubbing, supersonic separation, industrial lung).

Although the main purpose of biogas upgrading technologies is to remove CO2 from the gas stream, other contaminants may also be removed. However, specific contaminant pre-treatment (especially for hydrogen sulfide) is usually needed to improve the absorbent’s lifetime, lower regeneration costs, and reduce maintenance intervals.

The following is our list of biogas upgrading technologies:

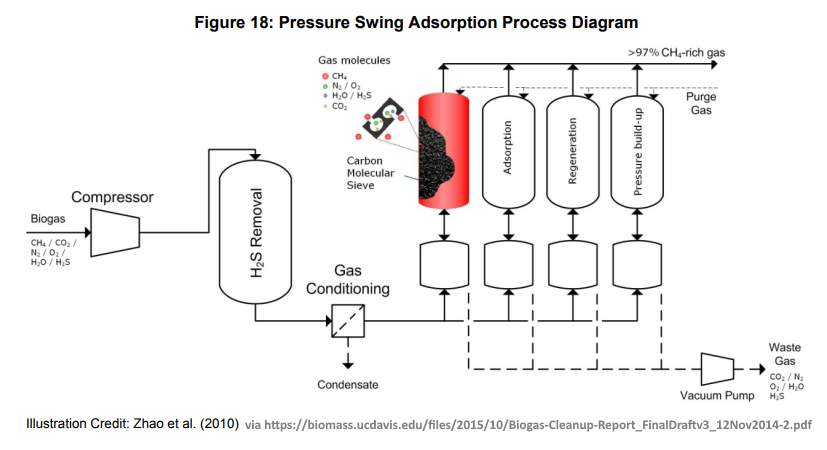

1. Pressure Swing Adsorption

Pressure swing adsorption (PSA) is a method for the separation of carbon dioxide from methane by adsorption/desorption of carbon dioxide on zeolites or activated carbon at alternating pressure levels. This technology is often applied in the gas treatment industry as it also effectively removes volatile organic compounds, nitrogen and oxygen from industrial gas streams.

2. Chemical Solvent Scrubbing

CO2 can also be removed from a gas stream by chemically binding it to certain dissolved compounds or liquid chemicals, for example, alkaline salt solutions and amine solutions.

There are two types of chemical solvent scrubbing and these are known as Alkaline Salt Solution Absorption, and Amine Absorption.

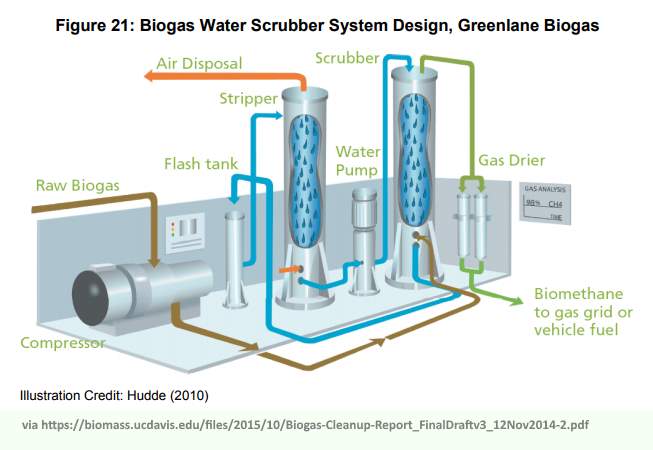

3. Pressurised Water Scrubbing

In this popular method compounds can be physically absorbed (or dissolved) into a liquid solution. Water is commonly used as he solvent due to low cost, low toxicity, and high availability. CO2 and H2S preferentially dissolve into water compared to CH4.

Like pressure swing adsorption, pressurised water scrubbing is a popular process for gas treatment because of its ability to simultaneously remove many other contaminants: ammonia, sulphur dioxide, chlorine, hydrogen chloride, hydrogen fluoride, aldehydes, organic acids, alcohol, silicon tetrachloride, silicon tetrafluoride, and siloxanes. (More from Greenlane Biogas here.)

4. Physical Solvent Scrubbing

Carbon dioxide and hydrogen sulphide can also be absorbed using liquid solvents other than water. The most industrially applied of these are organic glycols (e.g. polyethylene glycol). In return for higher cost and complexity than water scrubbing, these physical organic solvents allow for greater H2S and CO2 solubility than in water, allowing for lower solvent demand and reduced pumping.

Glycols for scrubbing biogas can be commercially found with such names as Genosorb® 1753, SELEXOL, Purisol, Rectisol, Ifpexol, and Sepasolv.

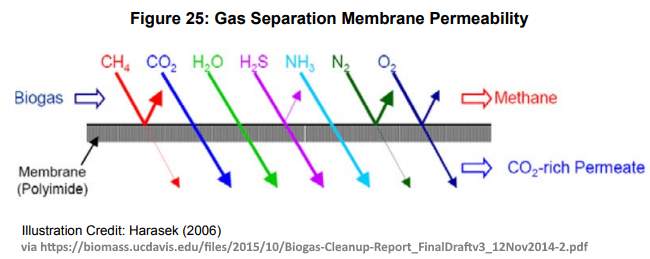

5. Membrane Separation

Membrane separation utilizes high gas pressures to create a large pressure differential across a nano-porous material (membrane) causing gas separation by several different mechanisms. These include molecular sieving (size exclusion), Knudsen diffusion (mean path difference), solution-diffusion (solubility difference), surface diffusion (polarity difference), and capillary condensation (adsorption).

Biogas generally requires pre-treatment to remove aggressive substances that can destroy the membrane material, at the current stage of development of these biogas upgrading technologies.

6. Cryogenic Distillation

Cryogenic distillation takes advantage of the fact that carbon dioxide will condense and freeze before methane condenses allowing the CO2 to be removed from the gas stream as a liquid or solid.

In cryogenic distillation, biogas is compressed anywhere between 260 – 435 psi (18 – 30 bar) and cooled by heat exchangers down to -45 to -59 °C until certain gases become liquefied. High system pressures are used to ensure that carbon dioxide remains in the liquid phase and does not freeze, which would clog the pipe and heat exchanger system. The liquefied carbon dioxide is then easily separated from the remaining gas, producing highly pure biomethane.

The Cryogenic Distillation process is only cost-effective at large scales, given the current stage of development of biogas upgrading technologies.

7. Supersonic Separation

A recent, novel approach to gas clean-up is supersonic separation, consisting of a compact tubular device that effectively combines expansion, cyclonic gas/liquid separation, and re-compression. A Laval nozzle is used to expand the saturated feed gas to supersonic velocity, which results in a low temperature and pressure (Figure 29). This causes the formation of water and hydrocarbon condensation droplet mist. A high vorticity swirl centrifuges the droplets to the wall, and the liquids are split from the gas using a cyclonic separator.

This gas conditioning technology has been used to simultaneously condense and separate water and hydrocarbons from natural gas. Further developments allowing for the bulk removal of CO2 and H2S are currently underway.

8. Industrial Lung

An industrial lung, also known as an ecological lung, is a bioengineered process which utilizes carbonic anhydrase—the enzyme present in our blood that catalyzes the dissolution of carbon dioxide formed from cell metabolism. Carbonic anhydrase pulls CO2 into the aqueous phase in an absorber column where it can be picked up by an absorbent. The CO2-rich absorbent is then regenerated by heat in a stripper column releasing a pure stream of > 90% CO2.

Laboratory experiments with biogas showed that they can purify it to 95 – 99% methane content with a CO2 content of less than 1%. Solutions is currently operating a large bench-scale unit.

Equipment Cost Comparison of Biogas Cleaning, Upgrading, and Utilization Technologies

The cost of full biogas upgrading to enable its use in commercial vehicle fleets and for injection into the natural gas grid for distribution to private and industrial natural gas customers has two classifications. These are cleaning and purification. The biogas must be both cleaned by the removal of unwanted constituents, such as water and CO2, and further purified to reduce low level contaminants to become very close to the composition of natural gas.

Biogas Cleaning Equipment Cost

Biogas cleaning, whether by adsorption, water scrubbing, or biofiltration, requires the purchase of a reactor vessel. Water and bio scrubbers require large-sized reactors and liquid pumps whereas dry absorption chambers do not. However, adsorption systems require the eventual change-out or regeneration of media. Thus, adsorption systems will have lower upfront and operating costs, but can have higher maintenance costs.

Hydrogen sulfide is usually the largest contaminant in biogas after CO2, and thus a primary target for cleaning. Consequently, the cost of biogas cleaning is often listed in terms of dollars per amount of sulfur or hydrogen sulfide removed. For gas streams with 500 – 2,500 ppm H2S, it generally costs $1.50 – $5.00 per pound of sulfur removed (McDonald and Mezei 2007). To remove moisture, a refrigeration or gas condensation system is often applied.

Biogas Upgrading Equipment Cost

Biogas cleaning is generally the lowest cost of the two requirements. Biogas upgrading technologies, on the other hand, are more complex and more costly. New and emerging technologies that consolidate biogas cleaning and upgrading, such as cryogenic distillation and supersonic separation, will generally be more expensive than already established technologies.

Membrane separation may be an exception, providing cost savings as long as membrane replacement rates remain low. However, among the three most common upgrading technologies—pressure swing adsorption, pressurized water scrubbing, and amine absorption—there is no clear winner in terms of initial cost.

Biogas upgrading technologies are also affected by economies of scale. The cost of treating biogas drops sharply with higher raw biogas throughputs.

Biogas Upgrading Technologies: Conclusion

Biogas Upgrading to Biomethane for grid injection or transport vehicle use requires more sophisticated cleaning than is necessary for electricity generation, and on top of that, the upgrading equipment has to be paid for.

Much of the upgrading equipment capital spending cost is offset by biomethane production not requiring a biogas engine, but upgrading equipment using traditional methods costs more to run than a generator.

Connection to the gas grid is usually more expensive than connecting to the local grid power lines, and upgraded biogas must also comply with stringent and expensive continuous testing requirements if it is to be accepted for grid injection. This entails laboratory costs, and commonly also a high level of management time liaising with the Gas Grid Company to demonstrate the continual quality of the injected biomethane.

Attribution:

This article is abridged with minor additions from the report on the biogas upgrading technologies: Public Interest Energy Research (PIER) Program, DRAFT INTERIM PROJECT REPORT, DRAFT Comparative Assessment of Technology Options for Biogas Clean‐up .

Frequently Asked Questions About Biogas Upgrading Technologies

1. What is biogas upgrading?

Biogas upgrading refers to the process of enhancing biogas to achieve high levels of methane purity, making it suitable for injection into the natural gas grid or for use as a transport fuel. The process also involves the removal of impurities like hydrogen sulfide, carbon dioxide, and other trace elements.

2. What are the different Biogas Upgrading Technologies used in biogas upgrading?

The most common technologies used in biogas upgrading include Pressure Swing Adsorption (PSA), water scrubbing, chemical scrubbing, membrane separation, and cryogenic separation. Each technology has its advantages and disadvantages and their application depends on the specific requirements and conditions of the biogas production facility.

3. What is biomethane?

Biomethane is a renewable form of natural gas produced from the decomposition of organic matter in an anaerobic environment (i.e., without oxygen). It is virtually the same as natural gas but has the advantage of being renewable and has a lower carbon footprint.

4. How much does it cost to produce biomethane?

The cost of producing biomethane is dependent on several factors including the technology used for biogas upgrading, scale of production, feedstock costs, and operating expenses. Additionally, financial incentives or government subsidies can have a significant impact on the overall cost of biomethane production.

5. Is biomethane production commercially viable?

While the costs associated with the high technology used in each of the biogas upgrading technologies necessary for biomethane production can be high, the commercial viability is:

- largely dependent on the market conditions,

- government policies, and

- the availability of feedstock.

In regions with supportive government policies and abundant feedstock supply, biomethane production can indeed be commercially viable. Importantly, by upgrading a output with the variable quality of raw biogas the AD plant operator obtains a quality controlled product which has an insatiable market demand.

Thus the added value of biomethane after applying any one of the biogas upgrading technologies is far higher than the biogas source.

6. How does biomethane compare to other forms of renewable energy?

Biomethane is unique in that it can be used directly in existing natural gas infrastructure, making it a versatile form of renewable energy. It is a renewable source of baseload power and can also be used for heating and transportation. However, its production and use must be balanced with the availability of feedstock and the environmental impact of its production.

7. Can biomethane help in reducing greenhouse gas emissions?

Yes, biomethane can significantly help in reducing greenhouse gas emissions. When produced from waste materials, it prevents these wastes from decomposing and releasing methane – a potent greenhouse gas – into the atmosphere. Furthermore, when biomethane replaces fossil-based natural gas, it results in a net reduction of CO2 emissions.

[Article first posted on 20 October 2017.]

But what about water (or chemical) costs being included in the economics, and why are they seemingly ignored so frequently in online studies & reports, when water is not cheap?

Brian: apologies for the delay in replying. I totally agree that all consumables must be included in pricing comparisons, or the economic basis is lost. I think that in solvent scrubbing applications, for example, it should be possible to re-use the solvent (chemical or water).

I would advise though that careful questioning of glib assumptions of 100% re-use, should be probed carefully, as even a small loss of solvent after recovery, may impose a significant cost.

These are some of the things a salesman may not reveal unless a client has a detailed knowledge of processes, and the forethought to ask such questions.

So, let’s have the comparitive economic & environmental analysis data, please??

Brian: Biogas systems vary. There is simply no one comparative review of these technologies which can be made. Each one will be specific to the project.

All I can suggest is that you go to the link in “Attribution” above, and read the case studies in Appendix B, and the cost information which is included. There may be a case study similar to your own project in there, which might give an indication of cost.

Thanks for a prompt response. What I was meaning was for you (or other) to take an example (or case study) for which data is available and provide a comparison of all possible methods for upgrading that data and tabulate?

I don’t think we can afford the sorts of prices for hydrogen sulfide removal which are given here. We are thinking of going down the additives route on this. Who is the best to go to and trustworthy on additives?

Karry: Although I am much complimented by your faith in my knowledge and ability to provide recommendations, the truth is that you, and others on this post, are asking more than can be provided in a public forum like this.

Bright Biomethane offers well-proven systems to upgrade biogas to biomethane in standard capacities from 40 Nm3 biogas / hr to 5,000 Nm3 biogas / hr (and higher). Bright Biomethane is one of the few suppliers thatcan deliver a complete range from small to large biogas upgrading installations.

Combine that with the fact that CO2, removed from the biogas, can be recovered and liquefied to create an extra source of revenue for the plant owner, and the prospect is good.

What i do not understood is actually how you are not really a lot more well known. You are seeming to be the source for many who need to know about biogas upgrading. You seem to get a lot of people willing to comment on your pages. You should be recognized therefore considerably more on the subject of this matter. Your own stuff is excellent. Catch onto my url link, for more info.

Which method is cost effective?

Ankit – As in so many things it is a case of “horses for courses”. Biogas plants vary so much in size and location, and in impurity. There will be no clear winner. On top of that there are questions of whether a technology supplier offers a service within a country and such matters as availability of spares and of any chemicals needed.

Membrane technology does appear to be very popular, but that is not necessarily a correct view.

if any reader can suggest there is a winning technology for all uses it would be great to read your comments, but otherwise contact the suppliers of these upgrading technologies and ask for quoted prices.

That’s the only sure way to find out the answer for a particular site. It does require potentially a fair amount of work on the behalf of the purchaser, but the investment warrants careful selection for a reliable, low cost upgrading solution..

Eminent blog, I am moving forward in my upgrading. Which when complete may be very rewarding, however I need to further expand. Which is best tech which you recommend. Tell us soon.

Would this system be thought about as being a Continuous stirred-tank (CSTR) reactor? or exists another name for this kind of reactor?

Hello,

Very Useful blog.

Thanks for sharing this blog

great post, very informative. did you see that Ofgem is now encouraging Biomethane. “Biomethane boost from RIIO-2 agreement”. https://www.endswasteandbioenergy.com/article/1585820/biomethane-boost-riio-2-agreement

Is there a substitute for steel wool in the scrubber for h2s?

Do you mind if I quote a couple of your articles as long as I provide credit and sources back to your blog? My website is in the very same niche as yours and my visitors would genuinely benefit from a lot of the information you provide here. Please let me know if this alright with you. Thank you!