The Process of Anaerobic Wastewater Treatment or “How it Works”.

Dealing with wastewater can be tough. We all want clean rivers and lakes, but often the process of getting there is complex. One effective method is anaerobic digestion wastewater treatment and before we start I will admit that it's also complex.

Wastewater treatment applications use tiny life forms to reduce the contamination in polluted water (effluent) without needing air, which sounds quite neat. 1

Anaerobic digestion also helps by turning waste into energy. Yes, it's true – your leftover food or sewage can actually power things up! But, while that's true for the way in which anaerobic digestion is predominantly used for foul sewage wastewater sludge treatment, energy production is usually a secondary benefit in the wastewater treatment industry. For most uses in organically contaminated industrial wastewater treatment the aim is to reduce the main organic loading to a level that is permitted for a sewer discharge. In other words to make it lower strength so that it is more like human foul sewage and won't overload the sewage works! In this blog post, we'll go through how this magic happens step by step.

It might just change how you think about throwing things away. 3

Ready for a cleaner future? Keep reading.

Key Takeaways

- Anaerobic wastewater treatment breaks down waste without oxygen. It turns pollutants into cleaner water and biogas.

- The process involves two main steps: biochemical breakdown and methane production. These steps change organic matter into energy.

- Different types of digesters, like lagoons and biofilm reactors, are used to treat various liquid wastes. They cost money to run but may make some income by selling the biogas for power or heating.

- Biogas made from the treatment is mostly methane. It can heat homes or generate electricity.

- Challenges include managing harmful substances that can stop the digestion process, and may also prevent the effluent (digestate) from being discharged to the sewer. Technical know-how is essential to keep these systems working well.

Introduction

Introduction

There are two distinct uses of Anaerobic Digestion for Wastewater Treatment:

- As a treatment process in its own right for primary sewage treatment/ organic industrial effluent, as known as a “UASB” etc.

- As a method of treating the sludge produced by Wastewater Treatment Plants.

Overview of Anaerobic Wastewater Treatment

Anaerobic wastewater treatment breaks down waste without using oxygen. This process is mainly used in sewage works and for food waste where high solids content liquids sludge, “pulps”, or “soups” can actually make money for the operator. But it also has uses in wastewater turning pollutants into cleaner water and while still outputting an energy source like methane gas it is low volume, and may not be enough gas to justify it being used.

Anaerobic wastewater treatment decomposes organic pollutants in water without the necessity of oxygen. This occurs in a unique vessel known as a bioreactor where oxygen-devoid microorganisms feed on the waste. 1 This technique is ideal for purifying water that is heavily laden with organic material. It is often a necessary stage of pre-treatment to allow factories, like food canning factories, to obtain consent to discharge their industrial effluent to a sewer

However, in other walks of life, the process primarily consists of two procedures: converting the waste into a slightly acidic mixture and subsequently producing methane gas from it. In most wastewater pre-treatment applications, this is a secondary output. This gas may or may not be utilised to generate clean energy. 1 The primary value lies in the reduction of the very high oxygen demand in organically contaminated fluid effluents. The entire operation aids us in managing sewage sludge and other types of waste more effectively, not solely cleansing the water but also creating a useful byproduct from the residues. Unlike aerobic biological treatment processes, with the possible exception of the UASB (Upflow Anaerobic Sludge Blanket) process, anaerobic digestion output (digestate) is too contaminated to discharge to the environment such as a watercourse. It is simply the first stage to get the polluted water clean enough for a watercourse discharge.

Applications in Liquid Waste (Effluent) Management

Applications in waste management use anaerobic digestion to deal with different types of waste. This includes municipal solid waste (e.g. collected food waste), sewage sludge (created during aerobic sewage treatment), and industrial effluents from food and beverage factories.

These places have a lot of organic pollutants. Anaerobic treatment cuts down these pollutants well. It lowers Biological Oxygen Demand (BOD), Chemical Oxygen Demand (COD), and Total Suspended Solids (TSS).

This makes the water cleaner. 1

Biogas produced during this process is a type of renewable energy. Factories and wastewater treatment plants can use it for power or heating. This helps cut down on using fossil fuels like coal or petrol.

Next, let's look at how anaerobic digestion happens step by step.

The Anaerobic Digestion Process

The anaerobic digestion process breaks down waste without using oxygen. This happens in two main steps, biochemical breakdown and methane production. But for wastewater applications turning organic matter into biogas and fertiliser is not the main aim – but getting a lower strength of contamination is the gain.

The Two Main Phases of Anaerobic Digestion

Anaerobic digestion is usually described as requiring 4 steps (hydrolysis, acidogenesis, acetogenesis and methanogenesis).

But to keep it simple for the purpose of this article. Let's say it turns waste into biogas (energy), reducing BOD and COD by an order of magnitude, in two main steps. This process is key for managing waste and making biogas. 2

- Microorganisms break complex organic stuff like food scraps into simpler short-chain acids. This step changes carbohydrates, proteins, and fats from sewage sludge into acids. It's a bit like prep work before the main cooking starts.

- Fermentation or Biochemical Breakdown and Acidification Phase: Methane Production Phase: Here, different tiny organisms take over to turn the short-chain acids into methane and carbon dioxide. Methane, a type of bioenergy, comes mostly from this step. It can power homes or even vehicles when cleaned up. Carbon dioxide, also made here, mixes with methane but doesn't burn. 3

Each phase relies on specific microbes that thrive in no-oxygen environments found in anaerobic digesters at wastewater treatment facilities. These stages ensure we get the most energy possible out of our wastes while cutting down pollution.

Key Biological and Chemical Reactions

- Central to anaerobic digestion, we encounter a sequence of steps that decompose waste. This procedure initiates with hydrolysis, where intricate organic materials transform into simpler substances.

Subsequently follows acidogenesis, transmuting these straightforward substances into volatile fatty acids (VFAs) and other residues. Then, acetogens intervene to turn these VFAs into hydrogen and acetate.

Eventually, methanogenesis takes the spotlight. In this phase, specific microorganisms named methanogens synthesise methane from hydrogen and acetate.

Creation of methane is critical for producing biogas—a mixture predominantly composed of methane and carbon dioxide. Methanogens maintain an essential role here; they are individual organisms that flourish without oxygen to generate methane efficiently.

Two primary types prevail: hydrogenotrophic types utilise hydrogen to synthesise methane, while acetoclastic types utilise acetate instead.

Elevated levels of VFAs signify an imbalance which could cease methane creation if not monitored. Interactions between species are also crucial as they assist in distributing compounds like hydrogen among different bacteria types, maintaining the system's stability.

Types of Anaerobic Digesters

Anaerobic digesters come in various forms. Each type has its own strengths for treating waste. Some digesters use lagoons, while others rely on different reactor designs. These systems help break down organic material without oxygen.

1. Anaerobic Lagoons

Anaerobic lagoons are large, artificial ponds. They can be up to 20 feet deep. 2 These systems treat animal manure effectively. Many farms in the United States use them for manure treatment.

They are cost-effective for large-scale waste management.

However, these lagoons face some challenges. Odour control is a major issue. Methane emissions can also be a concern. Regular maintenance is needed to manage sludge build-up in these lagoons. The output from anaerobic lagoons is never clean enough to discharge to a watercourse. In fact, it would be too strongly contaminated to be pumped into a sewer. It can only be stored for the next crop growth season and, at the right time of year, be used on the land as a fertiliser.

Understanding how they work leads us to the common anaerobic digestion processes next.

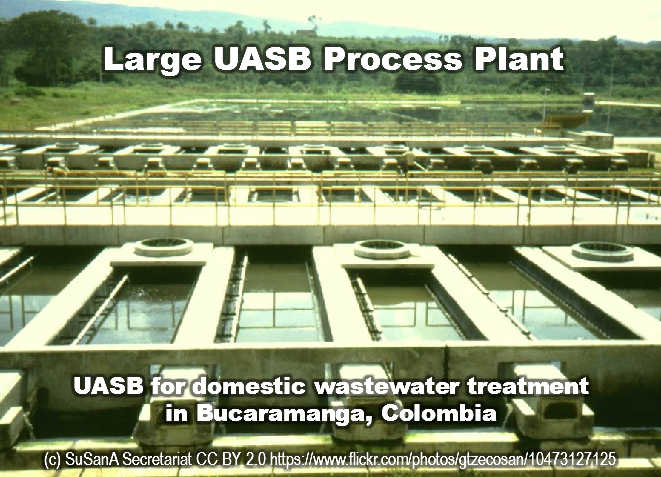

2. Anaerobic Sludge Blanket Reactors

Anaerobic Sludge Blanket Reactors (ASBRs) are effective for treating wastewater with high levels of organic pollutants. They are also known as Up-flow Anaerobic Sludge Blankets (UASBs). They work by allowing wastewater to flow through a blanket of sludge particles that float on top. 1 Within this sludge, microorganisms digest the organic matter without oxygen. This digestion process takes place in two phases, promoting efficient breakdown and biogas production. 5

The ASBR is well-suited for municipal wastewater treatment plants and industrial applications. However, it is rarely used. The flow through each UASB has to be quite low, for it to work. Regular maintenance is essential to avoid clogging in the anaerobic filter media. 1 With proper care, these reactors can greatly reduce contaminants while producing valuable biogas as fuel for power generation or other uses. However, you would not be likely to see an ASBR or UASB at your local Sewage Works.

The design allows for very good contact between the bacteria and the waste, leading to effective treatment. 2

Consequently, they excel at treating wastewater with high levels of organic content. As wastewater passes through UASBs, they significantly reduce Biological Oxygen Demand (BOD). This reduction helps maintain healthier water bodies after treatment.

Importantly, UASBs also produce biogas as a by-product during digestion. This biogas can be harnessed for renewable energy solutions like generating electricity or heating.

ASBRs and UASBs work best with warmer inflows, making them ideal in certain climates. The presence of methanogenic archaea plays a key role in this process, aiding in methane generation from organic matter.

Overall, these digesters can contribute greatly to modern sewage treatment plants by enhancing sustainability and reducing environmental impact while managing contaminants effectively. However, investment costs and a higher land take (footprint) usually prevent their adoption.

3. The Upward Flow Anaerobic Sludge Blanket

The Upward Flow Anaerobic Sludge Blanket or UASB process is a specialist use of anaerobic digestion wastewater treatment. It is quite rare to see, and it is based upon the idea that the particles in any sludge are gradually falling within the liquid they are in.

By creating a tank which is cone shaped, resting with the apex of the cone at the bottom, the water requiring treatment is introduced at the bottom. From there it flows constantly upward, very slowly. The flow rate is then balanced with the geometry of the tank so that a “blanket” of sludge, which is particles of organic matter and bacteria constantly falling gently in the water at the same speed as the water rises, stays perpetually suspended.

In effect it is balanced in a horizontal layer, above the bottom, within the UASB reactor vessel while the micro-organisms digest it. The extent to which the blanket is truly anaerobic can be questionable. The process was originally intended just as a high-quality water treatment method. It is not known to the author how reliably this process can be used to produce a good biogas yield.

However, it is a clever way in which to create a process in which the particles which digest slowly, would tend to reside in the reaction area/ sludge blanket. Individual particles can stay as long as needed until they are eaten by the bacteria. For this reason, the author assumes that there will be very little excess sludge created in UASBs.

However, it is a clever way in which to create a process in which the particles which digest slowly, would tend to reside in the reaction area/ sludge blanket. Individual particles can stay as long as needed until they are eaten by the bacteria. For this reason, the author assumes that there will be very little excess sludge created in UASBs.

This reduces the problem of sludge disposal and certainly reduces the cost of disposal of excess sludge remaining at the end of digestion. Sludge disposal can be expensive in other anaerobic digestion processes, especially where the material contains pollutants.

4. Expanded Granular Sludge Beds (EGSBs)

Expanded Granular Sludge Beds, or EGSBs, are an advanced type of anaerobic digester. They work well for treating industrial wastewater. 6 EGSBs recirculate wastewater, enhancing the treatment process.

This technology is similar to Up-flow Anaerobic Sludge Blanket (UASB) reactors but offers unique advantages.

EGSBs produce less sludge compared to other methods, making them more efficient. They improve energy recovery from wastewater too. However, they face challenges like high energy use and sensitivity to changes in operational conditions.

Advanced monitoring systems are needed to help maintain stability and performance. 6

These systems play a vital role in sustainable waste management practices today. Their ability to treat difficult wastewater makes them valuable in various settings.

By using EGSBs effectively, we can better manage organic pollutants while also generating renewable energy sources like biomethane.

5. Anaerobic Baffled Reactors (ABRs)

Anaerobic Baffled Reactors (ABRs) use a unique upflow design. This design features baffles that improve contact between wastewater and biomass. It helps to retain the active microorganisms needed for treatment.

The baffles also separate different processes, such as acidogenic and methanogenic actions. This setup optimises conditions for bacteria to thrive.

ABRs treat various types of soluble organic waste effectively in both municipal and industrial settings. They show high removal efficiencies for Chemical Oxygen Demand (COD) and Biochemical Oxygen Demand (BOD).

ABRs minimise biomass washout while promoting rapid recovery from shocks in water quality. With low sludge production, they generate significant amounts of methane gas, making them reasonably efficient as an energy.

Next, let’s explore biogas production from these systems… 7

6. Anaerobic Filter Reactors

Anaerobic filter reactors are effective for treating wastewater. Like Anaerobic Baffled Reactors, they use a fixed filter medium. 1 This allows anaerobic bacteria to form biofilms on the surface. Wastewater flows through this medium, where it interacts with the bacteria.

These reactors work well for warm industrial wastewater. They can handle streams that contain inorganics or chlorinated organics too. Regular maintenance is important to prevent clogging of the filter media.

The result? A significant reduction in organic contaminants and cleaner effluent for discharge or further treatment at wastewater treatment plants (WWTP). However, they have the same disadvantages as UASBs, ASBRs, and EGSBs.

7. Treating the Sludge Produced by Wastewater Treatment Plants (Sewage Works)

This is increasingly common.

It is the process of decomposing organic matter of municipal sewage sludge anaerobically under conditions of adequate operational control.

During the digestion of sludge, it is broken up into three different forms: (i) digested sludge which is a stable humus like solid matter with reduced moisture content (ii) supernatant liquor which includes liquefied and finely divided solid matter, and (iii) gases of decomposition like methane (CH4), carbon dioxide (CO2), nitrogen (N2) etc produced by microbial digestion.

The digested sludge is de-watered, dried up and used as sewage sludge fertilizer while the gases produced are used as fuel or for driving gas engines. The supernatant liquor is re-treated at the treatment plant along with the raw sewage. The tanks in which sludge digestion is carried out are called sludge digestion tanks.

Biogas Production

Biogas is made during the breakdown of organic waste. This gas mainly contains methane and carbon dioxide. It can be used to generate electricity, heat homes, or power vehicles. Biogas production helps reduce greenhouse gases while providing a clean energy source.

Composition and Extraction of Biogas

Biogas consists mostly of methane (CH4), which makes up 50 to 75 percent of its content. The gas also contains carbon dioxide (CO2), hydrogen sulphide (H2S), water vapour, and other trace gases. 3 This mixture forms during the anaerobic digestion process, where bacteria break down organic matter without oxygen. It is a crucial part of anaerobic wastewater treatment. 8

Extracting biogas involves capturing the gas produced in reactors during this process. Once collected, biogas can be purified into renewable natural gas (RNG).

This RNG can replace traditional fuels like natural gas in energy production or heating systems. The ability to generate electricity from biogas highlights its importance in sustainable energy solutions. 3

Utilisation of Biogas as Renewable Energy

Biogas serves as a valuable source of renewable energy. It can be used for heating, electricity generation, and even cooling systems. The energy produced from biogas supports boiler feedstock or combined heat and power (CHP) systems.

This usage reduces reliance on fossil fuels like petroleum. 9

Furthermore, studies show that the addition of Fe-TiO2 boosts methane yield to 100% in both anaerobic digestion and biomagnetic systems. With improved contaminant removal rates exceeding 75%, biogas production enhances environmental purification efforts while providing clean energy options. 9 Next, let's explore the benefits of anaerobic digestion for wastewater treatment.

Benefits of Anaerobic Digestion for Wastewater Treatment

Anaerobic digestion helps remove harmful organic waste from water. It also produces digestate, which can be used as a natural fertiliser for soil health.

Reduction in Organic Pollutants

By using AD technology, facilities can cut down harmful substances like COD and BOD in industrial effluents. Studies show it effectively reduces these pollutants, supporting environmental sustainability goals. Less pollution means healthier ecosystems and better sanitation for communities.

The digestate produced from AD is not a useless by-product; it serves as an excellent fertiliser. This helps create a circular economy where waste becomes useful again. Turning waste into energy promotes resource efficiency while tackling the issue of finding new landfill sites and incineration concerns.

Production of Digestate for Use as Fertiliser

Digestate is a valuable by-product of anaerobic digestion. This substance can be used as organic fertiliser in agriculture. 12 Optimal application rates range from 20% to 40% for leafy vegetables.

Using high concentrations—over 40%—can stress the plants. The digestate helps improve soil quality and boosts plant health.

The process also enriches the growing medium with beneficial bacteria, like Synergistetes. Biochar filtration further enhances its effectiveness as a fertiliser. Nutrients can be recovered from both liquid and solid fractions of digestate, supporting sustainable farming practices.

Challenges in Anaerobic Wastewater Treatment

Anaerobic wastewater treatment has hurdles to overcome. Contaminants, like hydrogen sulphide and other inhibitors, can disrupt the process. These challenges include handling complex waste streams from industries that produce high levels of COD and BOD.

Technical issues can arise too. Some systems suffer a poor reliability record and may need costly upgrades or repairs. Addressing these problems is key to success in this field. Interested in learning more about how our consulting advice can help our clients tackle these challenges? Complete our email form on the Contact page of this website.

Managing Contaminants and Inhibitors

Contaminants and inhibitors can harm anaerobic wastewater treatment. Emerging pollutants, like pharmaceuticals, are common in sludge samples. Studies show about 50% of these samples contain such contaminants. 13 These substances can hinder biogas productivity during the digestion process.

To tackle this issue, various remediation techniques come into play. Options include electrooxidation, ultrasonication, and ozonation. 13 Each method helps to break down or remove harmful pollutants from the sludge.

Enhanced solubilisation ensures a cleaner feedstock for biogas production.

Understanding how these pollutants interact is vital for improving treatment processes. Effective management strategies minimise their impact on anaerobic digestion systems. With proper control measures in place, we can boost efficiency and sustainability in wastewater treatment plants.

Technical and Economic Considerations

Technical and economic considerations are crucial for successful anaerobic digestion (AD) projects. Many facilities face challenges due to a lack of experience in managing these systems. 14 Economic hurdles can also be significant, affecting project feasibility. 15 Engaging stakeholders effectively is essential. They provide support and insights that help guide the implementation process.

Decentralised anaerobic systems offer local solutions suited to specific communities. This approach enhances sanitation, especially in underserved areas. Moreover, biogas produced from AD is valuable as renewable energy.

It can reduce reliance on firewood and fossil fuels for cooking. Training around these systems is vital to maximise their potential benefits and ensure sustainability.

Investment in anaerobic treatment technologies shows promise for improving wastewater management methods like mechanical biological treatment or cofermentation of household waste with other organic materials.

Technical knowledge will strengthen the impact of AD on reducing organic pollutants while producing digestate for use as fertiliser too!

Why More Utility Companies Should Consider Installing Anaerobic Digestion Wastewater Treatment Facilities at Sewage Works

It makes economic sense, right across the US (and globally) for more water companies to invest in anaerobic digestion of sewage sludge.

The EPA Says, and we quote: “Although the initial costs may be large, the digestion of food waste can be quite lucrative and the payback period can be less than three years, depending on the existing infrastructure at the wastewater plant”. See US EPA's Why-Anaerobic-Digestion.pdf There are also, other benefits other than economic.

In fact, wastewater treatment facilities are an ideal place to increase the diversion of food waste, by co-disposal of food waste with sewage sludge, especially when there is an anaerobic digestion facility available.

The following is an excerpt from the above pdf, which outlines why more Utility companies should consider installing Anaerobic Digestion Wastewater Treatment Facilities at sewage works:

- Existing Infrastructure – Many wastewater treatment facilities in the Pacific Southwest (US Region 9) and across the country, use anaerobic digesters to reduce the volume of the biosolids (sewage sludge) before they are taken off-site. The anaerobic digesters produce biogas which is either flared or used onsite as an energy source.

Therefore, the energy-capturing infrastructure is already in place at many facilities. - Existing Expertise – Wastewater treatment facilities already have the on-site expertise and years of experience dealing with anaerobic digesters; vessels that are difficult to operate without thorough knowledge.

- Located in Urban Areas – Wastewater treatment facilities are often located in dense, urban areas, where compost facilities are not. It makes logical sense for a highly populated area to ship organic waste to a nearby anaerobic digester where the energy content is recovered and the volume reduced.

The residual can then be trucked to compost facilities, which are typically located farther from urban areas. via USEPA.

While many local governments and municipalities may be interested in processing food waste in anaerobic digesters at treatment facilities, they may feel that the cost is a limiting factor.

However, there are many things to remember before immediately discounting this technology based on cost. - Payback period: Although the initial costs may be large, the digestion of food waste can be quite lucrative and the payback period can be less than three years depending on the existing infrastructure at the wastewater plant.

When a facility accepts food waste at a plant, it can charge the waste haulier a tipping fee for accepting the material.

In addition, there is a significant amount of money that will be saved in energy avoidance due to methane production. The excess energy can be sold back to the grid for profit. via USEPA.

Conclusion

Anaerobic wastewater treatment is a wise choice for managing organic waste. It uses bacteria to clean water without needing oxygen. This process reduces harmful pollutants and produces biogas, which can be used as energy.

Many industries benefit from this method, enhancing their waste management practices while cutting costs. As we face increasing environmental challenges, anaerobic digestion stands out as an effective solution for cleaner water and renewable energy generation.

1. What is anaerobic wastewater treatment?

Anaerobic wastewater treatment is a process where waste water from households or industries is treated in an environment without oxygen. This method involves the use of acidogenic bacteria, which helps to break down the waste into biofuels like ethanol.

2. How does anaerobic digestion work in wastewater treatment plants?

In wastewater treatment plants, anaerobic digestion works by breaking down biosolids and other organic materials through a series of biological processes. The decomposition takes place inside sequencing batch reactors or membrane bioreactors under controlled conditions.

3. Can the byproducts of this process be reused or recycled?

Absolutely! One major advantage of this approach is that it produces valuable byproducts such as phosphorus and polymeric substances which can be used for composting or codigestion purposes rather than being dumped in landfills.

4. What are some benefits of using anaerobically based treatments over traditional methods?

Traditional methods often involve combustion or incineration, leading to higher energy costs and environmental impact. However, anaerobically based treatments not only reduce these impacts but also produce biofuels during the secondary treatment phase – a win-win situation!

5. Are there any challenges associated with implementing this type of system?

While beneficial, implementing an anaerobically-based system could pose certain challenges including handling lignocellulosic wastes and maintaining denitrification stages effectively.

References

- ^ https://samcotech.com/anaerobic-wastewater-treatment-how-it-works/

- ^ https://watertreatmentservices.co.uk/how-anaerobic-wastewater-treatment-works/

- ^ https://www.epa.gov/agstar/how-does-anaerobic-digestion-work (2024-01-20)

- ^ https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8973982/

- ^ https://www.iwapublishing.com/news/flow-anaerobic-sludge-blanket-reactor-uasb

- ^ https://www.sciencedirect.com/science/article/abs/pii/S0048969718328043

- ^ https://www.sciencedirect.com/topics/engineering/anaerobic-baffled-reactor

- ^ https://www.sciencedirect.com/science/article/pii/S2211715624002455

- ^ https://www.sciencedirect.com/science/article/pii/S2588912521000266

- ^ https://www.sciencedirect.com/science/article/pii/S0301479723022466

- ^ https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6210450/

- ^ https://www.sciencedirect.com/science/article/abs/pii/S0956053X2100547X

- ^ https://link.springer.com/article/10.1007/s10311-022-01465-2

- ^ https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10702437/

- ^ https://www.sciencedirect.com/science/article/abs/pii/S0959652619317676

[First Published 4 November 2014. Updated 28 September 2024.]

I’m excited to discover this site. For once here is someone who appreciates that anaerobic digestion (AD) and biogas are not synonymous. Not all AD plants are “biogas” plants. OK. They may produce biogas, of course they will! But, in the anaerobic digestion plant where I work this plant is actually run to clean-up the water. So please stop calling these types of AD plants biogas plants.

Well said Broderie!

Broderie – Yes. We can see where you are coming from on this. It is a good point. “Anaerobic digestion plants” and “biogas plants” are not all the same.

Some are for the purpose of making biogas, others for other purposes, so we should take care not to call them all BIOGAS PLANTS?

I don’t think we’ve made that mistake on this page, but it is very likely that we have elsewhere in some articles.

We will take more care in future.

Thanks for sharing, this is a useful post. No longer am I puzzled about these green energy methods. Awesome article post. Green energy this way using WASTE is good for the environment I am sure. Looking forward to read more. Much obliged.

Mando – Yes. I see that you have created a good Pinterest page with a selection of small domestic biogas plants for warm climates, which are mostly buried below the ground. Why stop at 14 images though?

This is FAKE science. Sludge is mud. Doesn’t matter what you do with mud, it will still be mud.

We wanted to just grab a publication on this subject from our local biogas group. However I do think I found out much more from this blog post. I’m extremely delighted to see such stunning information being shared easily out there.

The biogas is making the money to pay the water cleaning cost. This is very good. We need this.