Two anaerobic digester mixer systems recently supplied by Landia are helping Yorkshire Water to progress with carbon emissions savings toward their target of Net-Zero carbon emission across the company by 2030.

High levels of biogas yield are also being achieved which indicate that these digesters are being well-mixed.

Read more about the use of this anaerobic digester mixer below:

Press Release 12 January 2022:

Mix to the max at Yorkshire Water’s major new Energy and Recycling Facility

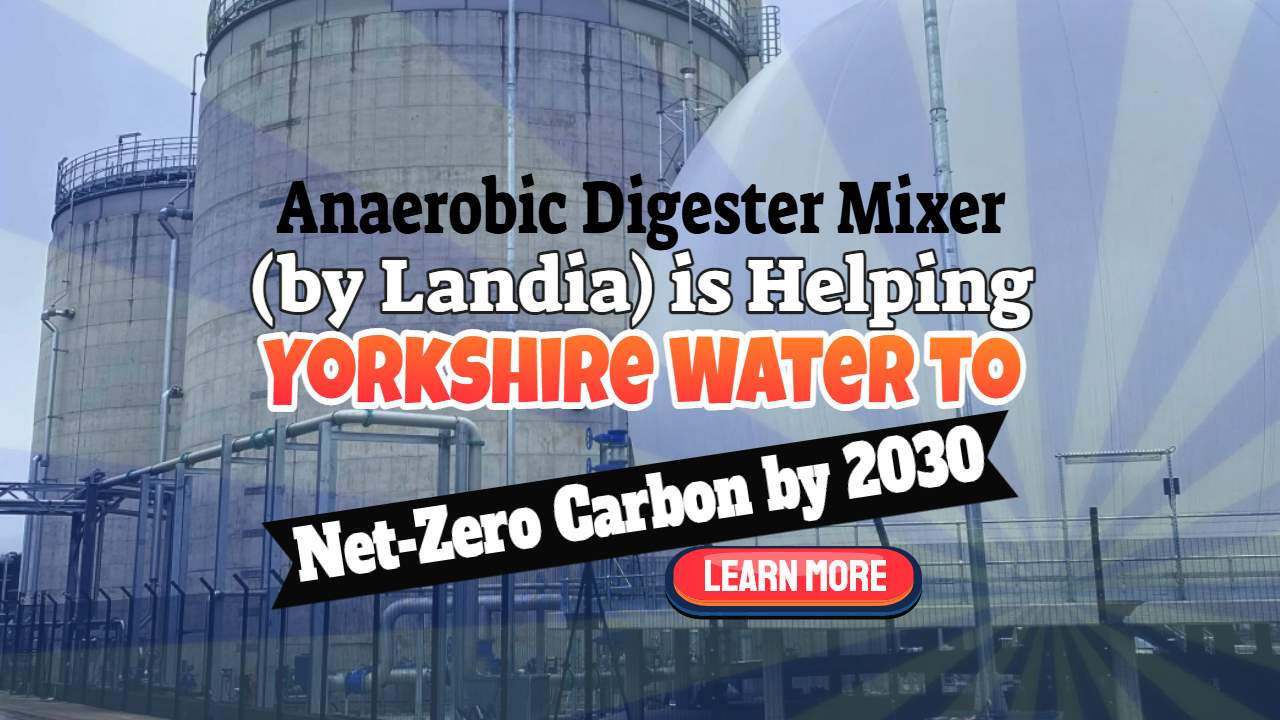

At Yorkshire Water’s new £50M Huddersfield Energy and Recycling Facility (E&RF), the digester mixing system from Landia is ensuring that total gas production can reach its anticipated 22,192 Nm3/d (normal cubic meter/day).

At Yorkshire Water’s new £50M Huddersfield Energy and Recycling Facility (E&RF), the digester mixing system from Landia is ensuring that total gas production can reach its anticipated 22,192 Nm3/d (normal cubic meter/day).

Designed, constructed and commissioned by J. Murphy & Sons Ltd (JMS), the Huddersfield E&RF is an integral part of Yorkshire Water’s long-term bio-resources upper quartile efficiency strategy.

Externally mounted on each of the two 7,306m3 concrete digesters, that contain thickened sewage sludge of up to 8% dry solids (DS), the Landia mixing system makes future servicing easy because there are no moving parts inside the tanks.

Anaerobic Digester Mixer Has Venturi Nozzles

Benefitting from the Landia chopper pump, which together with venturi nozzles ensures that the digesters are comprehensively mixed to maximise gas production, the mixing system is low on energy consumption and also reduces health and safety issues such as working from height.

A spokesperson for Yorkshire Water commented,

“We are very proud of our new Huddersfield Energy and Recycling Facility, which is comfortably meeting all its performance targets. This impressive new facility will play a big part in helping us achieve net-zero carbon by 2030”.

John Smith, Project Director for J. Murphy & Sons, added:

“Huddersfield E&RF shows the quality of the process engineering expertise that we can deliver for complex water and wastewater design and construction.

We understand that a good digester mixing system is very important to the success of an AD plant, so are pleased to see that our decision to choose Landia is paying benefits”.

Created as a regional sludge treatment facility to receive indigenous and imported sludge in both liquid and cake forms, Huddersfield E&RF has enabled Yorkshire Water to treat all of its sludge by anaerobic digestion.

The sludge load to the digesters is 24,000tDS/annum (total dry solids) or 65.753tDS of sludge per day, including up to a maximum of 11.880tDS per day of imported liquid sludge and 25.831tDS per day sludge cake respectively.

Two CHP engines produce peak electrical output of 2,390 kWh and a thermal output of 2,404 kWh.

Landia 01948 661 200

— PR Ends —