Two stage anaerobic digestion can provide both biogas plant process stability and the high rates of biogas production which come with a high degree of mass conversion. In may ways it provides a superior process design for biogas production, and yet it is seldom used in practice.

Two stage anaerobic digestion can provide both biogas plant process stability and the high rates of biogas production which come with a high degree of mass conversion. In may ways it provides a superior process design for biogas production, and yet it is seldom used in practice.

Why is that?

Unfortunately, due to the need for two reactor vessels, and increased pumping and control complexity, the initial investment cost is higher than for single stage anaerobic digesters, so AD facility designers seldom recommend 2-stage digester designs.

The Principles of “Traditional” Two Stage Anaerobic Digestion Design

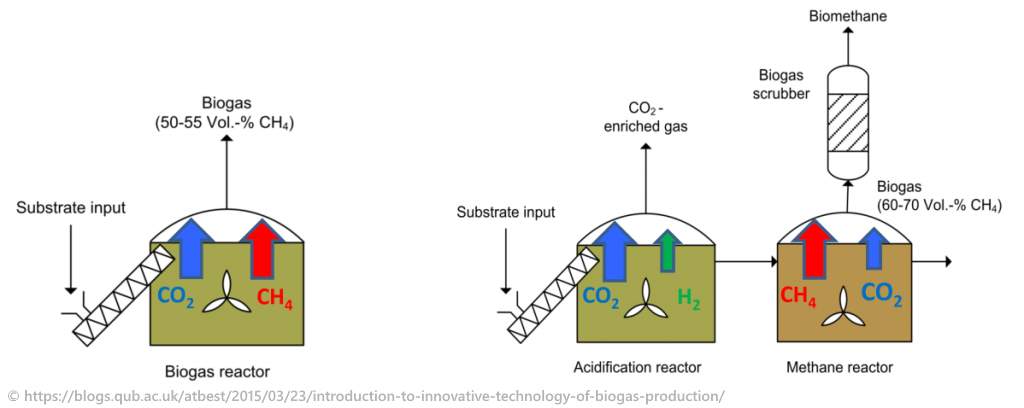

The biochemistry of the anaerobic digestion reaction takes place in a four phase degradation process. It consists of hydrolysis, acidogenesis, acetogenesis and methanogenesis.

Biochemists have for a long while known that each stage can be identified through the presence of separate characteristic bacteria/ micro-organisms in each phase. Also, the gas composition produced differs between the hydrolysis stage and subsequent stages, and the initial stages take place more rapidly than the subsequent stage.

This means that by splitting up the biogas production process into two stages (tanks) in which the first is used for “acidification” (loosely speaking – the first 2 steps), and the second stage (tank) for acetogenesis and methanogensis (methane production) there are advantages, as follows.

- At a biochemical level the environmental conditions in each digester stage can each be optimised to suit the prevalent bacteria.

- The first stage reactor tank can be smaller, tending to reduce total reactor volume needed, with associated reductions in mixing/ stirring energy consumption

- The second reactor produces a better quality biogas (often referred to as biomethane – although not a biomethane quality high enough for natural gas grid injection).

How Traditional Two Stage Anaerobic Digestion Works

The substrate (feedstock/ water mixture) is fed into the first reactor where acidification takes place leading to hydrogen production and accumulation of acids and alcohol, which are the precursor for the acetogenic microorganisms in the second stage.

The (biochemical) hydrolysis phase is either carried out batch wise or continuously and is connected to the second methanogenic reactor. The ratio of both reactor volumes is defined by the different retention time and generation time of the bacteria. This requires smaller volumes in the hydrolysis and bigger in the methane reactor, because the retention time in hydrolysis is significantly lower.

For fibrous and high solid content enriched input substrates, mixing problems could occur in the hydrolysis phase and form a floating surface layer (scum or crust). This can result in incomplete hydrolysis of the substrate.

In order to prevent this condition, proper stirring technology has to be chosen in the design phase. Due to conversion of solid carbon into the liquid phase a liquefaction of the substrate occurs. via blogs.qub.ac.uk-atbest

The biogas produced in the first stage contains a high percentage of carbon dioxide, and some hydrogen. The second stage tank provides a higher quality biogas than a single stage AD plant. It is also reported that plant stability is better for two stage anaerobic digestion plants.

In this discussion it is important to be aware of the fact that the hydrolysis referred to here is “biochemical hydrolysis” and NOT the “Thermal Hydrolysis“ (high temperature and pressure hydrolysis) stage applied often to sewage sludges, as the first stage (e. g. Cambi Hydrolysis Process). “High temperature and pressure hydrolysis” is normally only used for the breakdown of biomass (such as sewage sludges) which would otherwise mostly pass right-through any biogas plant run at normally applied (mesophilic) temperatures

Efficient two-stage anaerobic digestion systems for the production of biogas (e.g. methane) come in two types.

Two Types of Two Stage Anaerobic Digestion

The distinction between the two types is that in one, water is added to make a slurry and the solids and liquid is mixed pumped, and digested.

In the other the raw incoming material is placed in a reactor, sealed from the air and encouraged to ferment as a solid, usually with added “innoculum” containing anaerobic organisms sprayed onto the solid pile in a vessel.

In both types of anaerobic digestion process the substrate is moved through two separate reactor tanks connected in series.

Once the initial fermentation “dry” stage is complete, water is then added and a traditional wet-process methane producing second-stage takes place. This second type is known as a high solids phase and a low solids phase two stage anaerobic digester.

Whichever of these types is used, the sequence is the same.

As stated earlier, the four “biochemical stage sequence”, which is key to all anaerobic digestion processes is hydrolysis, followed by acidogenesis, acetogenesis, and methanogenesis.

Two key bacterial groups are at work during these stages, acetogens and methanogens.

During the first stage, hydrolysis, acidogenesis, acetogenesis occur.

During the second stage, biogas is produced in a second reactor by a methanogen-rich anaerobic culture which has in-effect been cultured in the low solids medium.

All the stages (process steps) are shown in our video below:

Transfer of effluent from the second reactor to the first reactor assists in maintaining a suitable pH in the high solids phase, in mixing there is an effect of seeding the first stage with methanogens.

In two stage reactors, where both are liquid phase based, methane may be produced from both reactors and recovered.

Overall Energy Recovery Can be Best from 2 Stage Biogas Plants

Researchers point out that the supremacy of two-stage on traditional one-stage anaerobic digestion (AD), in terms of overall energy recovery (ER) from biomass has frequently been proved.

It is due to the different growth rates, preferences and requirements of the microorganism species involved in each step, that physical separation in two independently performing reactors is an option to which enable specific conditions for the microbiology at each stage to be set to optimise output.

The first stage reactor is often called the hydrolytic reactor, of a two stage AD system.

Anaerobic digestion (AD) is the biological degradation of organic material in the absence of air.

An anaerobic digester is a man-made system that harnesses this natural process to treat waste, produce biogas that can be converted to heat and electricity and anaerobic digestate, a soil improving material.

Anaerobic Digestion (AD) is the preferred stabilisation process for the treatment of wastewater sludges and organic wastes. The process provides volume and mass reduction and delivers valuable renewable energy with biogas production.

A company called Arrowbio is one of the best known internationally, for using two stage anaerobic digestion within its process designs.

[box type=”info” style=”rounded” border=”full”]Page updated January 2018.[/box]

Why limit your discussion to just the wet/wet anaerobic digestion two stage AD Plant design options? There is also the possibility of two stages dry/wet. The GICON Process is a two-stage dry-wet anaerobic digestion process operated in batch mode. Take a look at http://www.gicon-engineering.com ‘s digester design.

Two stage digesters cost more to build than the single stage plants which are by far the most common. A new technology option is to add a pre-treatment stage which can pay for itself because it removes ammonia and phosphorus, allowing high ammonia feedstocks to be used and for an additional product profit stream. See https://anaerobic-digestion.com/phosphorus-crisis-nutrient-recycling-anaerobic-digestion/

I am looking for 2 stage anaerobic digestion plant designer/ installers. So far I have found just ArrowBio’s process. It would be useful if this page contained a list of all the top AD plant contractors which offer their own 2 stage AD facility designs. Nevertheless, do let me say I like this website.

Chris. In this case (and also I notice other writers), talk about 2 stage anaerobic digestion but I am unclear. The hydrolysis stage, is that counted as a stage? You do not mention this so it i unclear. Don’t mind me. Keep posting. Congrats generally on website.

The term ‘Two Stage’ refers to the separation of the entire process physically by using two different tanks that are operating to two different sets of conditions. In anaerobic digestion there are four stages overall but they can be split into two broader groups. Generally, the groups will be categorised into the Acid forming phase (Hydrolysis and Acidogenesis stages 1 and 2) and Methane forming phase (Acetogenesis and Methanogenesis stages 3 and 4). In the above work I think it is split into the two groups with one contains 3 stages and the other 1 stage (Group 1 [Hydrolysis, Acidogenesis, and Acetogenesis]: Group 2 [Methanogenesis]).

I wouldn’t agree with the grouping listed. The bacterial biome (for want of a better word) present in the Acid forming phase prefer conditions more acidic meaning certain types of bacteria grow. The Methane forming stage (I am referring to Acetogenesis and Methanogenesis here) bacteria proliferate under the same conditions as each other but are not as tolerant to conditions present in the Acid forming bacteria. However, with biology being biology, nature will adapt and every reactor setup is different.

So in answer to your, yes hydrolysis is counted as a stage. It occurs within the first stage (with acidogenesis) of the two stage process.

Did you notice that the original two-stage biogas company ArrowBio still has its original website, but in fact they did seem to be trading as arrowbio-global until recently [2020]. There must be a story about that… Just wondering?

Hello I am so thrilled I found your site, I didn’t really expect to find much written about biogas. I didn’t think many people knew about it, although we’ve always done it on our smallholding.

Regardless I am here now and would just like to say thanks for a very revealing publication, and a altogether interesting website. keep up the superb job. what’s an URL?

Forgive my lack of knowledge on the topic, however I should ask: the bacteria produce CH4, then there is a lot of hand-waiving stating it will produce electrical power. How does the gas produce electrical power, and more significantly, how is the production of CH4, which is a powerful GHG, avoided going into the environment throughout the procedure?

An impressive share, I have sent this on to a colleague who will doing some further analysis on this. We might use this and adapt our plant to 2 stages after considering the 2 stage biogas process further. He actually bought me a beer last night, to say thanks. Meanwhile would you mind updating your blog with more details? It’s helpful for us.