Are you puzzled by the term “digestate” and what it entails? If you're dealing with waste management or agriculture, understanding digestate can be crucial. Many environmental researchers and professionals grapple with the challenges of managing organic waste effectively. 1 And we get it—differentiating between compost, digestate, and other soil conditioners can be confusing.

Here's one fact: Anaerobic digestion produces both biogas and a byproduct known as digestate. 2 But what is digestate exactly? This article will explore its definition, production processes, various types, and practical uses—from fertilising soils to generating energy.

Stick around for a clear explanation that will demystify this essential component in sustainable farming! 3

Key Takeaways on the subject of What Is Digestate: Understanding The Definition And Uses Of Digestate

- Digestate is the byproduct of anaerobic digestion, comprising both solid fibrous material and liquid, rich in nutrients like nitrogen (N), phosphorus (P), and potassium (K).

- Farmers use digestate as a natural fertiliser to improve soil structure, enhance crop growth, and reduce reliance on chemical inputs.

- The screw separator process splits digestate into nutrient-rich liquids for agriculture and fibrous solids that can be composted.

- Compliance with standards such as PAS110 ensures high-quality output from biogas plants, making the digestate safe for agricultural use.

Defining Digestate

Digestate has often been defined as the material remaining in the digester after the anaerobic digestion of an organic feedstock. But, that description hugely undervalues the fact that it is truly the original “Natural Fertiliser”.

Digestate is the leftover material after breaking down organic matter in an anaerobic digester. It comes from food waste, animal manure, and other biodegradable materials.

Video thumbnail image above: This image shows the special equipment used to irrigate digestate during crop growth to gain the best fertilising effect while minimising any risk of nutrient run-off into watercourses that would cause pollution.

Composition and Production Process

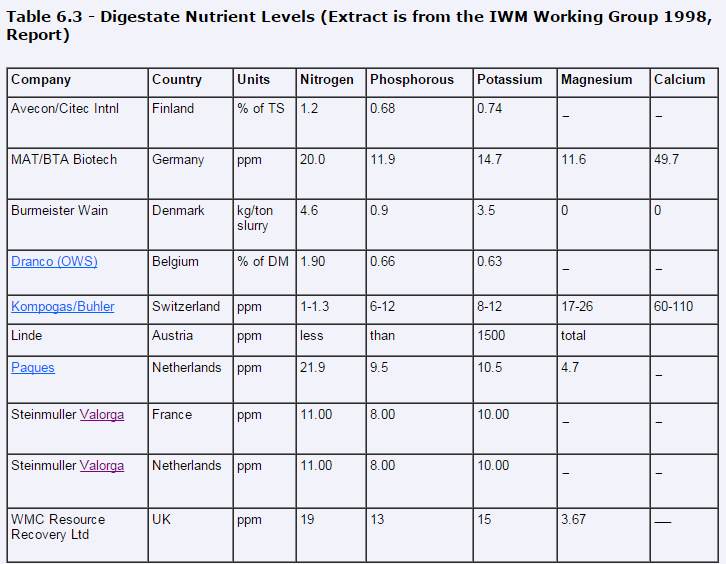

Digestate consists of solid fibrous material and a liquid portion. The chemical make-up varies based on the feedstock used, such as sewage sludge, animal wastes, energy crops, municipal waste, agricultural residues, and industrial by-products. 1 Both physical separation processes like screw separators and biological treatments get employed to split the digestate into nutrient-rich liquid and fibrous solids.

The process begins with anaerobic digestion of organic materials. Bacteria break down matter in oxygen-free conditions. 2 This creates biogas for energy production and leaves behind digestate rich in nutrients like nitrogen (N), phosphorus (P), and potassium (K).

It undergoes further treatment to enhance its usability depending on end-use requirements.

Digestate slurry

Digestate slurry is the liquid part of digestate produced after anaerobic digestion. It contains key plant nutrients like nitrogen (2.3 – 4.2 kg/tonne), phosphorus (0.2 – 1.5 kg/tonne), and potassium (1.3 – 5.2 kg/tonne). 1 Farmers can use it as a natural fertiliser to improve soil structure and boost organic content.

This liquid fertiliser helps crops grow better by providing essential micronutrients. It reduces the need for chemical inputs, making farming more sustainable. 2 Researchers find it valuable for soil amendment in intensive cropping systems, thus enhancing crop production while reducing environmental impact.

Liquid and Fibrous Digestate After a Screw Separator Separation

The screw separator splits the digestate into liquid and fibrous parts. The nitrogen moves to the liquid fraction, while phosphorus sticks to the solid part. This process helps manage solids and liquids separately. 3

The fibrous digestate can make high-quality compost due to its amendment properties. 4 The liquid part might go through more treatments like membrane filtration or NH4-stripping for better use in agriculture or other applications.

Types of Digestate: Acidogenic and Methanogenic

Acidogenic digestate is fibrous and contains organic acids. It has high moisture retention properties, making it useful in soil improvement. Methanogenic digestate, on the other hand, is a nutrient-rich sludge that includes ammonium and potassium. 1 This type of digestate is produced after methane production as a byproduct during anaerobic digestion.

Uses of Digestate

Digestate boosts plant growth and restores land health.

As a Fertiliser

Digestate serves as a powerful fertiliser. It reduces reliance on chemical alternatives, promoting sustainable farming. 2 The digestate provides key nutrients like nitrogen, phosphorus, and potassium.

Typical nutrient values are 2.3 – 4.2 kg/tonne of nitrogen, 0.2 – 1.5 kg/tonne of phosphorus, and 1.3 – 5.2 kg/tonne of potassium.

Farmers apply it to improve soil structure and water retention capabilities. 2 This enhances crop growth while keeping the environment healthy. 6 In land reclamation….

In Land Reclamation

Transforming waste into value doesn't stop with fertilisation… It's also vital in land reclamation. Digestate provides a rich source of carbon and nutrients, rejuvenating degraded soils.

This process is recognised by the European Union as efficient recycling. 7

Land reclamation projects often struggle with poor soil quality. Introducing digestate can enhance these soils, making them fit for planting crops again. The experiment in Roncade, NE Italy showed that it stabilises organic carbon, improving soil health for agriculture. 8

For Energy Generation

Digestate can generate energy from biogas plants. This by-product of anaerobic digestion produces gas for heat and power. 9 Anaerobic digestion is an industry-standard technology for biogas production in many countries like Denmark, Germany, and the UK. 5

Using co-digestion with different feedstocks boosts stability during long-term reactions. Methanogenic digestate plays a big role here by producing methane gas used to create electricity and heat.

National regulations ensure digestate quality meets safety standards before it’s used further.

This energy-from-waste process supports renewable energy goals while reducing landfill use. The digestate produces valuable fertiliser and contributes to sustainable energy solutions across various industries.

Adding Product Value to Digestate

Digestate can be turned into valuable products using different methods. For example, digestate evaporators help reduce liquid waste and side-stream ammonia stripping removes harmful gases….

Digestate Evaporators for Anaerobic Digestion Plants

Digestate evaporators drain liquid digestate to obtain concentrated nutrients. Vacuum evaporation creates valuable, concentrated nutrients by reducing digestate volume. This process helps meet strict EU regulations for environmental protection and hygiene.

Reducing the volume decreases disposal costs and benefits waste management systems. 10

Utilising these evaporators in anaerobic digestion plants allows efficient nutrient recovery from biowastes like pig slurry and agricultural wastes. These devices enhance the overall value of the digestate, making it more suitable for various applications such as fertiliser or land reclamation. 11

Sidestream Ammonia Stripping

Sidestream ammonia stripping removes ammonia from liquid digestate streams effectively. This process creates marketable fertilisers like ammonium sulphate or urea, boosting economic value.

It also increases biogas production and improves digestate quality. 12

By using sidestream ammonia stripping, anaerobic digestion plants can produce renewable fertilisers that help reduce reliance on synthetic fertilisers. The stripped ammonia can be sold as a valuable product in favourable market conditions, making the whole operation more attractive financially. 12 This method benefits both waste management and agricultural sectors by providing high-quality organic fertiliser options while enhancing biogas yield. 13

Digestate Monitoring for Productive Biogas Plant Operation

Monitoring digestate is crucial for a productive biogas plant operation. 14 Checking key chemical parameters, like the FOS/TAC ratio, helps maintain optimal conditions. This ratio indicates the balance between fatty acids and alkalinity in the digester.

A balanced system boosts biogas yield and prevents slowdowns. 15

Early detection of issues ensures regulatory compliance and reduces downtime. Regular monitoring saves maintenance costs by addressing problems before they escalate. Keeping an eye on these factors guarantees smoother operations and consistent energy production from biogas plants.

Digestate vs. Compost

Digestate and compost both improve soil health. Digestate is faster in releasing nutrients, while compost takes longer.

Similarities and Differences

Both digestate and compost contain vital nutrients like nitrogen, phosphorus, and potassium. These are essential for plant growth. They also improve soil structure and fertility. Nutrient content varies based on the feedstock used. 16

Digestate undergoes anaerobic digestion, while compost forms through aerobic digestion. Digestate is faster to produce than compost. Both can work as sustainable alternatives in crop production. 17

Moving onto advantages of digestate over compost…

How Digestate Differs from Compost

Digestate is technically not compost although it resembles it in physical and chemical features. Compost is produced by aerobic decomposition by aerobic organisms. Those include fungi and bacteria which are able to break down the lignin and cellulose in the feed materials to a greater degree.

Digestate is the solid residue of the original input product to the digesters that the microbes can not use. It also includes the mineralised remains of the dead bacteria from within the digesters.

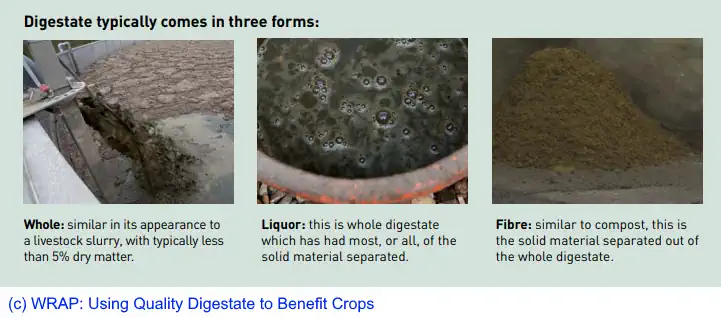

3 Kinds of Digestate or Should we say “Natural Fertiliser”

Digestate can be found in 3 forms:

- fibrous,

- liquor, or a

- sludge-based combination of the two forms.

In 2 stage biogas process systems, various forms of digestate originate from various digestion tanks. In single-stage digestion systems, the two portions will certainly be incorporated together and, if preferred, these can be separated by more processing.

Digestate typically consists of substances, such as lignin, that can not be broken down by the anaerobic microbes. The digestate may consist of ammonia which is phytotoxic above certain levels and could hamper the development of plants if it is used as a soil-enhancing material.

The application of digestate has been shown to hinder plant illness and aid in the induction of resistance. Digestate application to farmland has a direct beneficial effect on soil-born conditions and an indirect result by stimulation of biological activity.

Digestate Quality Contaminants and Uses

Advantages of Digestate Over Compost

Digestate offers clear advantages over compost. It provides higher levels of phosphorus and potassium in the soil, which boosts plant growth better than synthetic nitrogen fertilisers. 6 The nitrogen use efficiency in digestate ranges from 20% to 25% over three years, promoting healthy crop yields.

Digestate helps reduce N loss while encouraging plant uptake. 6 This dual benefit of organic matter and nutrients means crops receive essential elements more effectively. Furthermore, it supports sustainable farming by recycling waste into valuable resources like biomethane and biofertiliser, further enhancing soil health and productivity. 18

Standards and Regulations

Countries have rules to ensure digestate is safe. These rules make sure it’s good quality and doesn’t harm the environment.

Quality Protocols

Publicly Available Specification (PAS110) sets strict rules for making quality digestate in the UK. If biogas plants follow these standards, they can sell their digestate as “bio-fertiliser”.

The Environment Agency published this Quality Protocol on 17 March 2014. 19 This document explains how to produce and use good-quality outputs from anaerobic digestion of biodegradable waste.

Following PAS110 helps ensure the safest and most effective use of digestate. It covers everything from testing for harmful substances to ensuring nutrient content is right. Compliance with these protocols means the digestate can replace synthetic fertilisers safely…

benefiting both farmers and the environment. 20

Compliance and Monitoring

Compliance with standards like the Quality Protocol PAS110 is crucial. These rules ensure that digestate meets safety and quality benchmarks. Regular testing of feedstock characteristics helps in producing high-quality digestate.

Monitoring parameters such as nutrient levels, pathogens, and contaminants keeps operations optimal. 2

The Biofertiliser Certification Scheme offers assurance that digestate is safe to use. This scheme validates that it has met all regulatory requirements. Continuous monitoring prevents potential risks in biogas plant operations.

Using tools like sidestream ammonia stripping can enhance compliance efforts further. 21

Conclusion to What is Digestate?

Digestate is a valuable product of anaerobic digestion. It enriches the soil and boosts crop yield. It's sustainable, reducing the need for chemical fertilisers. Monitoring ensures high quality and safe use.

What is Digestate? – FAQs

1. What does digestate mean?

Digestate is the material left after anaerobic digestion of organic matter, like food waste or animal manure.

2. What is digestate made of?

Digestate consists of decomposed organic materials, including lignin and inorganic nitrogen compounds like NH4+.

3. How is digestate used in farming?

Farmers use digestates as an organic fertiliser to improve soil health and crop yield.

4. Can digestates replace chemical fertilisers?

Yes, they can serve as a substitute for mineral fertilisers, providing essential nutrients without harmful chemicals.

5. What role do methanogens bacteria play in producing digestates?

Methanogenic archaea break down organic matter during anaerobic digestion, leading to biogas production and forming valuable by-products like struvite.

6. Is there a quality protocol for using digestates?

Yes, the Digestate Quality Protocol ensures that composted products meet safety standards for use in agriculture and horticulture.

References

- ^ https://anaerobic-digestion.com/digestate/

- ^ https://europeanbiogas.eu/wp-content/uploads/2015/07/Digestate-paper-final-08072015.pdf

- ^ https://www.sciencedirect.com/science/article/abs/pii/S0960852418316274

- ^ https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8002686/

- ^ https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10466263/

- ^ https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8401478/

- ^ https://www.sciencedirect.com/science/article/pii/S0167198724000503

- ^ https://www.researchgate.net/publication/333728289_Re-use_of_digestate_and_recovery_techniques

- ^ https://www.sruc.ac.uk/media/glephuum/digestate_information_sheet_1___introduction_to_digestate.pdf

- ^ https://blog.anaerobic-digestion.com/digestate-evaporators-for-anaerobic-digestion-plants-add-product-value-and-aid-disposal/

- ^ https://mpra.ub.uni-muenchen.de/95770/1/MPRA_paper_95770.pdf

- ^ https://blog.anaerobic-digestion.com/side-stream-ammonia-stripping/ (2024-06-24)

- ^ https://www.ncbi.nlm.nih.gov/pmc/articles/PMC9691913/

- ^ https://blog.anaerobic-digestion.com/digestate-monitoring-for-productive-biogas-plant-operation-and-low-downtime/

- ^ https://www.celignis.com/digestate-analysis.php

- ^ https://www.sciencedirect.com/topics/agricultural-and-biological-sciences/digestate

- ^ https://www.biogas-info.co.uk/about/digestate/

- ^ https://www.stgreenpower.co.uk/insight/the-benefits-of-using-digestate-instead-of-fertiliser-a-sustainable-solution-for-agriculture (2023-11-16)

- ^ https://www.gov.uk/government/publications/quality-protocol-anaerobic-digestate (2014-03-17)

- ^ https://assets.publishing.service.gov.uk/media/5a7c657aed915d6969f44953/426765_EA_QP_Anaerobic_Digestate_web.pdf

- ^ https://www.researchgate.net/publication/363566711_Digestate_Management_and_Processing_Practices_A_Review