In today's world, finding sustainable ways to produce what we consume is crucial. As professionals with years of experience in the anaerobic digestion industry, we've seen firsthand how innovative solutions, like sourcing biogenic CO2 from the carbon dioxide byproduct of biogas upgrading, can transform challenges into opportunities.

CO2 sourced from agricultural and food waste sources for beverage production is a very promising opportunity. This approach not only reduces waste but also produces a high-quality ingredient essential for making all of our favourite fizzy drinks.

Our journey through this article will uncover how turning biowaste into food-grade, biogenic carbon dioxide offers a safe and environmentally friendly alternative to traditional sources requiring fossil fuels.

With the increasing demand for low carbon footprint production processes, this method stands out as a beacon of sustainability.

By focusing on renewably sourced CO2, we're stepping towards a greener future—one sip at a time.

Biogenic Carbon Dioxide from Biogas Production and Utilization

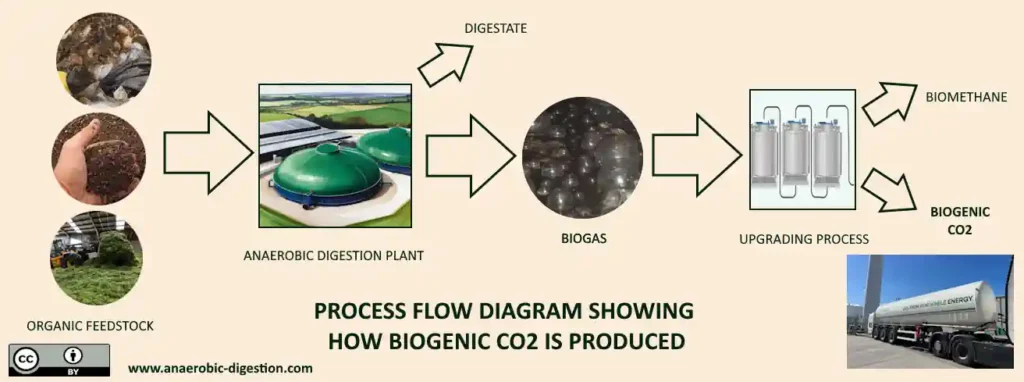

Biogas is produced from organic waste, such as crop waste and manure, and, to an extent, from energy crop sources. It is more and more often being upgraded to biomethane, a renewable energy source with multiple applications. The biomethane upgrading process leads to the production of biogenic CO2 at a purity of around 99% as a byproduct.

Through further purification steps, such as cryogenic distillation, a product of 99.9% purity can be achieved that also meets the other requirements to be used as a food ingredient.

Read on as we delve deeper:

The First Stage of Biogenic CO2 Production: Upgrading biogas to biomethane

Biogenic CO2 is a byproduct of the process used to purify (upgrade) biogas to biomethane. Just producing biogas is not enough to produce biogenic CO2. It needs to be upgraded.

But more and more AD plants are upgrading it and, in the process, turning their biogas into biomethane because it is a smart move. That means that there are plenty of existing biomethane plants that could be retrofitted for CO2 production.

The CO2 production process involves:

- Cleaning and refining the raw biogas (comprising about 60% methane and 40% CO2) that bubbles up to the surface during the anaerobic digestion process to biomethane, making the methane content interchangeable with gas-grid quality natural gas, and

- Making the carbon dioxide byproduct pure enough for food industry standards – crucial for carbonating drinks like beers and ciders, with the advantage that the CO2 is renewable.

Valorization of biogas by-products

It is biomethane that is the key player in producing food-grade biogenic CO2 and demand for it is growing, so the availability of this byproduct is rising fast.

Whether the CO2 is derived from fossil fuels in a fertiliser plant, ethanol fermentation, or from natural wastes on an energy farm, it's all about getting rid of impurities that don't belong in beverages.

At the moment, the most common source of biogenic CO2 in the UK is CO2 made from ethanol production. It uses either bioethanol or potable ethanol, both of which are natural sources.

However, that's where sustainability ends. The underlying process of ethanol production generally relies on fossil fuels to heat and distill it. Compare that with anaerobic digestion, which draws on the renewable biogas energy (and frequently also the unused hot cooling water) that it creates to produce the heat and power that it needs for its CO2 process.

Strict quality controls on biomethane also apply to CO2

Biomethane is produced either:

- for sale as a low particulate emission (clean) transport fuel, or

- for injection into the gas grid as a natural gas replacement.

For either use, strict quality standards apply. Probably the most exacting until now have been the requirements of the gas distribution network (grid) operators.

The gas grid operator continuously monitors biomethane production, which must be of the highest quality before it is permitted to be injected into the local gas main. The result has been that all biomethane plant operators are very familiar with operating their equipment to the highest standards at all times.

Producing biogenic CO2 to exacting standards will extend the existing quality control ethos that these businesses already apply to their biomethane production.

Production of food-grade CO2 by cryogenic distillation

Cryogenic distillation is the favoured technology used to turn biogas into food-grade CO2. This process cools the gas until it becomes a liquid. Then, it separates the CO2 from other gases based on their boiling points.

Food and drink makers use this clean CO2 to make soft drinks and other beverages bubbly.

This method follows the strict quality standards set by agencies like the EIGA (European Industrial Gases Association). It ensures that the CO2 is safe and of high quality for food industry use. Making carbonated drinks with this CO2 meets all customer expectations for taste and safety.

The Benefits of Food-Grade CO2

Food-grade CO2 from any biogenic source is safe and eco-friendly, unlike fossil-derived CO2. It is high-quality for making beverages and meets strict quality standards set by EIGA.

Safe and environmentally friendly compared to fossil-derived CO2

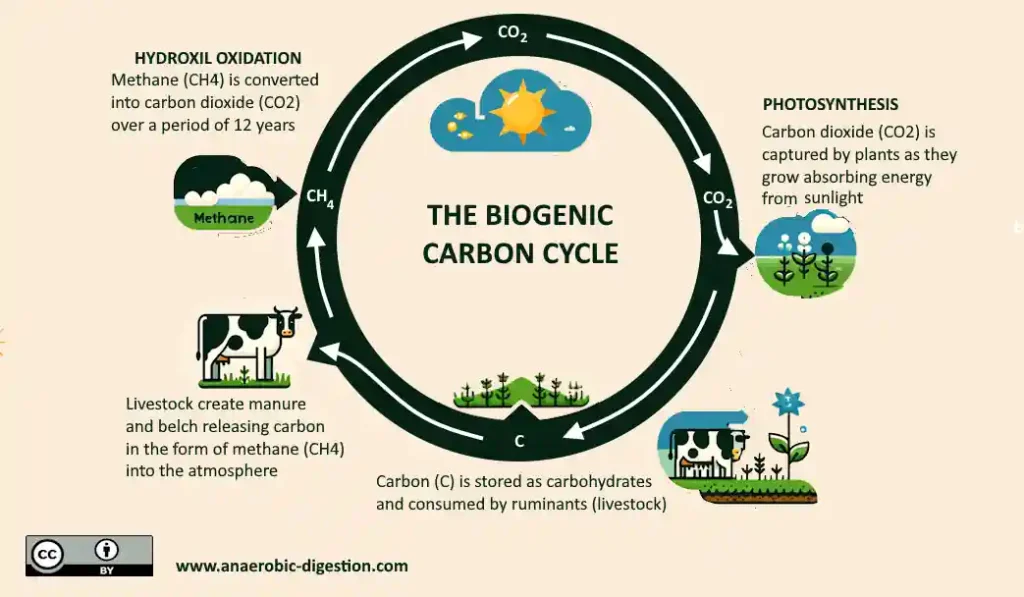

Biogenic CO2 is a game changer for the planet and your production line. Unlike fossil-derived CO2, which adds new carbon to the atmosphere, biogenic CO2 from anaerobic digestion recycles carbon that's already in the natural carbon cycle.

This means we are not increasing greenhouse gases when we use it. Plus, using waste from food processing keeps our approach circular – nothing goes to waste.

So, choosing biowaste-sourced CO2 doesn't just elevate your product; it shows you care about the future too.

Meeting quality standards (EIGA) and demonstrating compliance

Meeting quality standards, such as those set out by the European Industrial Gases Association (EIGA), is vital for anyone in the food industry using biowaste-sourced CO2. These standards ensure that the CO2 used in beverage production is safe and of high quality.

Their biogenic CO2 from biomethane production meets strict quality criteria set by authorities such as the European Industrial Gases Association (EIGA). As a result, it is no different from traditionally sourced fertiliser plant CO2 and yet comes right at the heart of sustainable practices.

Not only does biogenic CO2 from biomethane production offer a greener alternative to traditional fossil fuels, but it also supports circular economy goals by turning waste into value. Plus, with demand on the rise for eco-friendly options, this approach ticks all the boxes – safe, high-quality, and kinder to our planet.

To comply, producers need to follow specific guidelines – from how they collect and process biowaste to how they purify and test the final CO2 product. All UK anaerobic digestion facilities likely to offer biowaste-sourced CO2 will have been required to apply pasteurization to comply with the Animal Byproducts Regulations and will operate under one of the relevant AD industry quality certification schemes. The certification process includes detailed checks like ensuring there's no contamination with harmful substances, which are key for maintaining top-notch safety and quality.

Demonstrating compliance with EIGA standards involves thorough documentation and regular testing. Every batch of food-grade CO2 will come with a certificate of analysis, showing it meets all necessary criteria.

This not only builds trust among consumers but also opens doors to new markets that demand high environmental and safety standards. For businesses in the beverage sector, staying aligned with these regulations means investing in state-of-the-art processing technologies and rigorous environmental monitoring.

Achieving this level of certification highlights a commitment to excellence, underscoring a brand’s dedication to sustainability and customer well-being.

Utilizing carbon dioxide from organic waste sources

We have already explained how making biomethane from biogas from organic waste (also known as biowaste) is a clever way to make food-grade CO2. But, using carbon dioxide from this source has further hidden benefits. These come from the fact that the ability to valorise multiple biogas products, brings them the first real opportunity for the agricultural industry to manage their waste sustainably.

The ability of the agricultural community to gain an income from their biogas plants gives them a sustainable method to manage their agricultural waste, food waste from household kitchens, and even the leftovers from food processing that would have, until recently, been sent to landfills.

This source of CO2 can also be combined with carbon capture and storage (CCS, also referred to as carbon sequestration), in which the idea is to change the carbon emission status of non-renewable fuels from greenhouse gas emitting to “carbon emission neutral” by:

- capturing carbon dioxide on its way to passing into the atmosphere in flue gases

- storing the carbon dioxide in some way for a very long time, such as beneath the sea in old oil and natural gas fields.

Although much has been talked about CCS, it has so far failed to gain investment from the energy industry or governments. The combination of flue gas carbon capture and placing the captured CO2 in geological storage still needs to be demonstrated to be technically viable, let alone affordable.

And yet, in contrast, the development of anaerobic digestion plant CCS through the use of biogenic CO2 (carbon dioxide from organic waste sources) in fizzy drinks, is, as explained later in the “SLR Consulting Project Example,” already proven to be viable at Crofthead AD and Apsley Farms, albeit at a somewhat higher price than “traditional CO2“.

So, valuing this technology based on the CO2 price alone does not do it justice. There are many benefits to this form of carbon capture (CC). Think of it as giving waste a second life, where both the planet and your fizzy drink can win.

This process fits perfectly into what's called the circular economy. It's all about reuse and keeping resources in use for as long as possible.

By tapping into the realms of anaerobic digestion, biogas, and digestate (a liquid natural fertiliser and a fibrous compost), we're hitting three, not two, birds with one stone:

- making our soil richer,

- making renewable fuel, and

- obtaining some high-quality CO2 for beverages along the way.

The anaerobic digestion industry is still relatively young, and during its first years, it was used almost entirely only for the production of electricity using modified diesel engines. The output of the residue after the digester (digestate) was considered to have little monetary value.

In the mid-2010s, AD plant developers moved on to upgrade their biogas to biomethane and sell it as a more valuable vehicle fuel, and they also started to inject it into the gas grid for better revenue.

Compost and digestate produced from food processing waste in biogas digesters are now also being repurposed as soil improvers or fertilisers, promoting sustainable agricultural practices and providing income.

Using CC, to stop wasting the CO2 byproduct, is the next logical step to fully valorising the anaerobic digestion process. And, after those, there are other potential market opportunities for selling CO2 across various industries beyond food and beverage production. However, CO2 for fizzy drinks is the largest potential market.

The climate impact of using biogenic CO2, or indeed, storing it to keep it out of the atmosphere, will play a pivotal role in exploring opportunities for CCS in the biogas industry. Not least, aligning with efforts to reduce carbon emissions in the food and beverage industry in their transition to decarbonization via the use of renewable energy sources and biogenic carbon sources within beverage manufacturing processes.

SLR Consulting Project Example: Crofthead Biogas

Crofthead AD is a sizable agricultural AD facility, near Dumfries, run by Carbon Capture Scotland that exports energy in the form of biomethane injected into the local grid.

CO2 is separated from the methane in biogas when upgraded to biomethane and is typically vented to the atmosphere.

A bolt-on CO2 capture plant was developed separately, with agreements for electricity and CO2 purchases made with the main AD plant. The main AD plant has been successfully commissioned and handed over to the client, and it is injecting biomethane into the grid.

SLR Consulting supported the Crofthead biomethane project as the owner's engineer and subsequently as project manager. SLR also completed the technical due diligence of the carbon capture project for an initially interested funder.

SLR provided technical support to both sides around electrical integration, safety controls, and mechanical integration. This included amendments to the pressure relief system to prevent the release of methane to the CO2 plant. The SLR team also supported the coordination of site works during commissioning, minimising downtime of the main AD plant.

On separate projects, SLR has also supported the auditing of the products of CO2 from AD against food grade standards, including EIGA requirements.

Conclusion: Cryogenic CO2 for Beverage Production – A Sustainable Solution for the Future

The idea of using the previously discarded carbon dioxide byproduct of “biogas upgrading” into food-grade biogenic CO2 for use in drinks is new, but as the successful implementation at the Crofthead Biogas Facility shows, it is already a proven viable technology.

Turning waste into something valuable by providing the fizz for drinks can become a really substantial asset not least for businesses seeking ways to achieve their decarbonisation targets year after year.

However, not everything is perfect.

While turning biowaste into food-grade CO2 offers many pluses like reducing greenhouse gases and saving resources, there are challenges too, and the biggest for most people is that setting up the technology can be expensive.

However, the same was said 10 years ago about justifying the cost of upgrading biogas to biomethane, and yet over the past 3 to 4 years, more new UK biogas plants have been commissioned with upgrading than without it.

Above all, biogenic CO2 is a technology right on the cusp of rapid development because it makes sense in so many ways and is a unique climate-remediating innovation. Forgive us for saying it's smart science meeting eco-friendly business all in one fizzy sip!