The global shift toward renewable energy has positioned biomethane upgrading equipment suppliers as key players in sustainable fuel alternatives. Biomethane upgrading systems transform raw biogas into high-purity methane suitable for vehicle fuel or grid injection, creating valuable revenue streams from organic waste.

This article examines leading biomethane upgrading equipment suppliers, comparing their technologies, market focus, and solutions particularly beneficial for smaller agricultural operations.

We've evaluated suppliers based on technology diversity, scalability, energy efficiency, and support for small-scale operators. Whether you're managing a large municipal waste facility or a modest farm-based digester, understanding these technologies is crucial for maximising your biogas potential.

Read on for our list of biomethane upgrading equipment suppliers:

1. Kanadevia Inova

Product: BioMethan Gas Upgrading

Kanadevia Inova offers comprehensive biomethane upgrading solutions through their BioMethan technology. Their systems convert raw biogas from various sources into high-purity biomethane while capturing carbon dioxide as a valuable by-product.

“Kanadevia Inova Grows Renewable Gas …” from www.kanadevia-inova.com and used with no modifications.

Unique Selling Proposition

What distinguishes Kanadevia Inova is their dual technology approach, offering both membrane separation and amine scrubbing processes. This flexibility allows clients to select the most appropriate technology based on their specific site conditions and requirements.

Markets Served

- Municipal green waste facilities

- Organic household waste processors

- Agricultural biomass operations

- Sewage treatment plants

- Landfill gas recovery sites

Biogas Flow Rates

- Modular design for Membrane Systems 500-2000 Nm³/h and 250-2000 Nm³/h for amine scrubber systems

- Scalable for larger capacities

- Container construction for flexible installation

- Multiple units can be combined for increased capacity

Technology Options

Membrane Technology

Their membrane system separates carbon dioxide from methane through selective gas permeation. CO₂ passes through the membrane surface more quickly than methane, which is retained and collected as product gas.

This plug-and-play solution requires no additional operating resources such as water or heat, making it ideal for sites with limited utilities.

Amine Scrubbing

Their chemical process uses an amine solution that absorbs carbon dioxide as raw gas flows through a packed column. This technology achieves biomethane purity up to 99.9% and is particularly suitable for sites with available heat sources.

The process is highly robust when handling impurities in the biogas stream and offers exceptional plant availability.

“Gas Upgrading – Kanadevia Inova” from www.kanadevia-inova.com and used with no modifications.

Additional Features

Kanadevia Inova also offers its Advanced Contaminant Removal (ACR) system, designed to handle high levels of volatile organic compounds while maintaining low operating costs. This makes it particularly valuable as an add-on to membrane installations or for upgrading existing plants.

Explore Kanadevia Inova's Biomethane Solutions and discover how their dual-technology approach can optimise your biogas upgrading process. Visit Kanadevia Inova's Website

2. Bright Renewables

Product: PurePac Biogas Upgraders

Bright Renewables positions itself as a one-stop shop for biogas upgrading, offering their PurePac systems for both biogas and landfill gas applications. Their technology utilises advanced membrane separation specifically designed for biogas purification.

“PurePac Medium biogas upgrading project …” from www.bright-renewables.com and used with no modifications.

Unique Selling Proposition

Bright Renewables reportedly stands out with its patented control system that enables biomethane-to-grid in minutes with exceptional uptime. Their system quickly adjusts the Wobbe index and methane range, maintains stable gas quality, and minimises maintenance through continuous monitoring.

Markets Served

- All biogas-producing industries

- Grid injection projects

- Bio-CNG/LNG production facilities

- Facilities seeking CO₂ liquefaction

Biogas Flow Rates

- PurePac Compact: 100-750 Nm³/h

- PurePac Medium: 750-1,500 Nm³/h

- PurePac Grand: 1,500-2,500 Nm³/h

- PurePac Supra: 2,500-3,500 Nm³/h

- Scalable beyond 3,500 Nm³/h

“Biogas Upgrading: PurePac | Bright …” from www.bright-renewables.com and used with no modifications.

Technology

At the core of Bright Renewables' upgrading systems is a highly efficient 3-stage membrane technology. Their process begins with pre-treatment, where moisture and contaminants like H₂S are filtered out. The gas is then compressed to reach the required pressure before entering the membrane system.

Key Benefits

- High separation efficiency (≥99.5%)

- Low methane slip (≤0.5%)

- Ultra-low methane slip with CO₂ liquefaction (≤0.1%)

- Energy consumption of 0.26 kWh/Nm³ of raw biogas

- UltraLow-E design available with consumption as low as 0.17 kWh/Nm³

- Operational in as little as 30 weeks

Discover Bright Renewables' PurePac Range

Find the perfect biogas upgrading solution for your specific flow rate requirements. Learn More

3. Bennamann

<< Coming Soon! >>

4. DMT Clear Gas Solutions

Products: Carborex MS and Carborex PWS

DMT Clear Gas Solutions offers two primary technologies for biomethane upgrading: Carborex MS (membrane separation) and Carborex PWS (pressurised water scrubbing). Their systems are designed for high efficiency and reliability across various applications.

Unique Selling Proposition

DMT distinguishes itself through its dual technology offerings and focus on energy efficiency. Their systems feature advanced process control that optimises performance while minimising energy consumption and methane losses.

“DMT Clear Gas Solutions – Carborex MS …” from biogasworld.com and used with no modifications.

Markets Served

- Agricultural biogas plants

- Food waste processing facilities

- Wastewater treatment plants

- Industrial organic waste processors

- North American and European markets

Biogas Flow Rates

- Small-scale: [No model size listing was found] Nm³/h

- Medium-scale: 250-750 Nm³/h

- Large-scale: 1,000-5,000 Nm³/h (Contact DMT)

- Custom solutions for larger capacities

“DMT Carborex MS Biogas Upgrading To …” from www.energy-xprt.com and used with no modifications.

Technology Comparison

| Feature | Carborex MS (Membrane) | Carborex PWS (Water Scrubbing) |

| Methane Recovery | ≥99% | ≥99% |

| Energy Consumption | 0.22-0.3 kWh/Nm³ | 0.2-0.3 kWh/Nm³ |

| Water Requirement | None | Minimal (closed loop) |

| Chemical Requirement | None | None |

| Best For | Small to medium flow rates | Medium to large flow rates |

Find Your Ideal DMT Upgrading Solution

Compare membrane and water scrubbing technologies for your specific application. Request Information

5. Malmberg

Product: Malmberg COMPACT

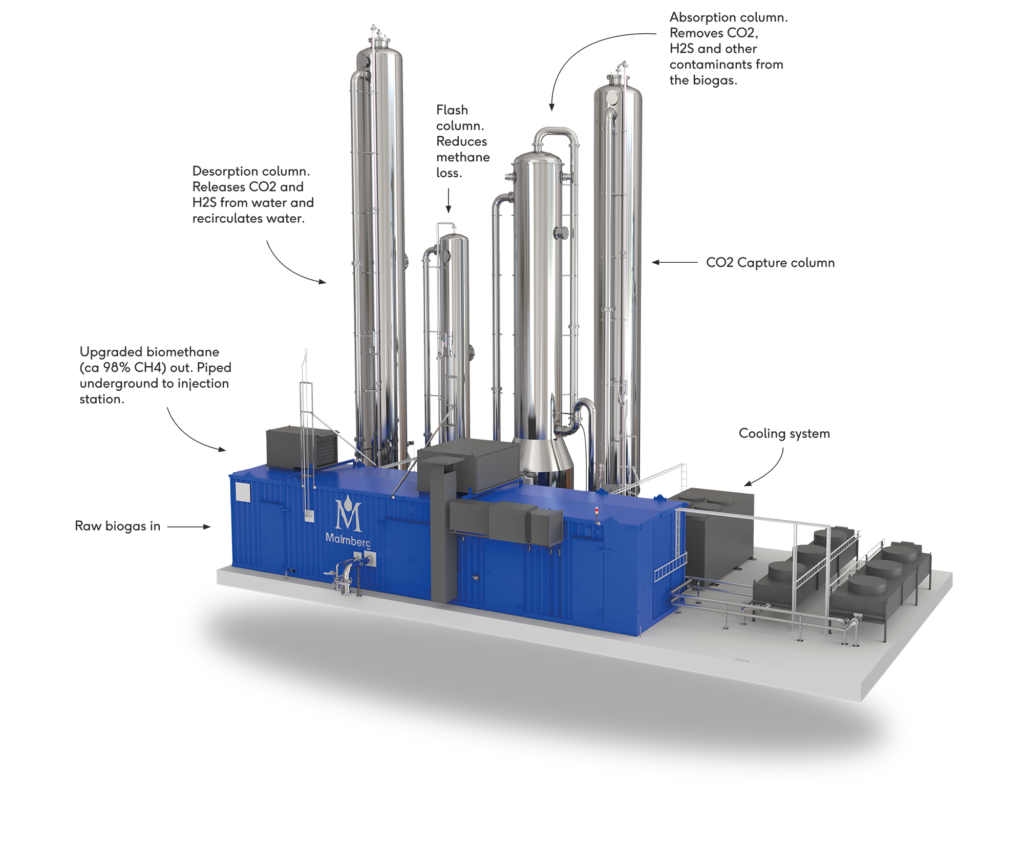

Malmberg specializes in water scrubbing technology for biogas upgrading through their COMPACT system. With over 25 years of experience and more than 140 references worldwide, they're one of the most established players in the biomethane upgrading market.

Unique Selling Proposition

Malmberg's strength lies in their proven water scrubbing technology and extensive experience. Their systems are known for reliability, low operating costs, and excellent methane recovery rates. The company offers standardized, containerized solutions that simplify installation and commissioning.

“Biogas – Malmberg EN” from www.malmberg.se and used with no modifications.

Markets Served

- Municipal waste treatment

- Agricultural biogas plants

- Industrial wastewater facilities

- Food and beverage industry

- Strong presence in European markets

Biogas Flow Rates

Malmberg Supply 9 models as follows:

- Lowest flow rate model 100 to 360 Nm³/h

- Highest flow rate model 2,000 to 5,000 Nm³/h

“Biogas Cleaning and Upgrading …” from ohioline.osu.edu and used with no modifications.

Technology

Malmberg's water scrubbing technology exploits the different solubility of CO₂ and CH₄ in water. Under pressure, carbon dioxide dissolves more readily in water than methane. Their process involves compressing the biogas and introducing it to water in an absorption column, where CO₂ is absorbed while methane passes through.

The technology requires no chemicals and operates in a closed water loop, making it environmentally friendly. The system achieves methane recovery rates of over 99% and produces biomethane with 97-99% purity.

Explore Malmberg's Proven Upgrading Technology

Discover why over 140 facilities worldwide trust Malmberg's water scrubbing systems. Malmberg, with its tried and tested technology, has long been one of the most respected biomethane upgrading equipment suppliers. View Malmberg Solutions Here

Small-Scale Solutions: Biomethane Upgrading for Agricultural Operators

For smaller farmers and agricultural biogas plant operators, several suppliers offer specialised solutions that make biomethane upgrading economically viable at lower flow rates. These systems help agricultural operations diversify revenue streams and maximise the value of their biogas production.

Comparing Small-Scale Options

| Supplier | Suitable Products | Min. Flow Rate | Technology | Key Advantage |

| Kanadevia Inova | BioMethan (Agricultural Package) | 100 Nm³/h | Membrane | Complete solution with AD plant integration |

| Bright Renewables | PurePac Compact | 100 Nm³/h | Membrane | Lowest energy consumption with UltraLow-E |

| DMT Clear Gas | Carborex MS Small | 40 Nm³/h (Not verified) | Membrane | Lowest minimum flow rate available |

| Bennamann | CAPCH4® | 50 Nm³/h | Proprietary Technology | Proven reliability with minimal maintenance |

| Malmberg | COMPACT 100 | 100 Nm³/h | Water Scrubbing | Proven reliability with minimal maintenance |

Benefits for Agricultural Operators

Advantages of Upgrading

- Higher value product compared to electricity generation

- Multiple revenue streams (biomethane, CO₂, digestate)

- Reduced dependency on electricity feed-in tariffs

- Potential for on-farm vehicle fuel production

- Access to renewable fuel incentives and credits

- Improved carbon footprint and sustainability credentials

Challenges to Consider

- Higher initial investment than CHP

- Grid connection may require additional infrastructure

- Operational expertise required

- Regulatory compliance for gas quality

- Ongoing monitoring and maintenance needs

Financing and Support

Many biomethane upgrading equipment suppliers now offer financing options, operational support, and maintenance packages specifically designed for small-scale agricultural operators. Some also provide remote monitoring services to ensure optimal performance without requiring extensive on-site expertise.

DMT Clear Gas Solutions offers the lowest entry point with their 40 Nm³/h system, making them particularly suitable for the smallest operations. Kanadevia Inova's agricultural package provides a comprehensive solution that integrates anaerobic digestion with upgrading technology, ideal for operations looking to build a complete system from scratch.

Find Your Perfect Small-Scale Upgrading Solution

Compare options from leading suppliers to maximise the value of your agricultural biogas.

Final Considerations When Choosing a Biomethane Upgrading Supplier

When selecting a biomethane upgrading equipment supplier, consider these key factors beyond just the initial purchase price:

- Technology match: Different upgrading technologies have varying strengths depending on your specific feedstock, flow rate, and end-use requirements.

- Energy efficiency: Operating costs over the system's lifetime often exceed the initial investment, making energy-efficient designs crucial for long-term profitability.

- Methane recovery: Even small differences in methane slip can significantly impact both revenue and environmental performance.

- Scalability: Consider future expansion possibilities and whether the system can be upgraded to handle increased capacity.

- Service and support: Local technical support, spare parts availability, and remote monitoring capabilities are essential for maintaining high uptime.

- Track record: Suppliers with proven installations similar to your planned operation reduce implementation risk.

For agricultural operators, biomethane upgrading represents a significant opportunity to diversify revenue streams beyond electricity generation. While the initial investment is higher than a CHP system, the potential returns through biomethane sales, carbon credits, and, in some regions, renewable fuel incentives can provide a compelling business case.

The technology has now matured to the point where small-scale operations can benefit from the same upgrading processes previously only economical for large facilities. With solutions available starting from just 40 Nm³/h, even modest farm-based biogas plants can transform their raw biogas into valuable biomethane for grid injection or vehicle fuel.

Ready to Upgrade Your Biogas Operation?

Contact these leading biomethane upgrading equipment suppliers to discuss your specific requirements.