A Biogas Power Plant is essentially another name which has been coined recently for an anaerobic digestion plant. These are, also known as biogas digesters. As any technology becomes more successful and reaches a wider audience, so does it generate new names and the anaerobic digestion technology sector is no exception.

A Biogas Power Plant is essentially another name which has been coined recently for an anaerobic digestion plant. These are, also known as biogas digesters. As any technology becomes more successful and reaches a wider audience, so does it generate new names and the anaerobic digestion technology sector is no exception.

To cover the entire topic which surrounds the biogas power plant subject of biogas power generation on this page, we have included sections below on biogas power plant cost, biogas power plant design including a buried tank design layout. For those seeking a link to a biogas power plant ppt and a biogas power plant pdf we also have those as well lower down in this long article.

The term biogas power plant is probably most often used in India, so we have information for those readers and on the Biogas Power Plant Manufacturers in India, a biogas power generator.

Description of a Biogas Power Plant

A biogas power plant is a decentralized energy system, which can lead to self-sufficiency in heat and power needs, and at the same time reduces environmental pollution.

The components of a modern biogas power (or anaerobic digestion) plant include:

- manure collection,

- anaerobic digester,

- effluent treatment,

- gas storage, and gas use/electricity generating equipment.

The fresh animal manure is stored in a collection tank before its processing to the homogenisation tank, which is equipped with a mixer to facilitate homogenisation of the waste stream. The uniformly mixed waste is passed through a macerator to obtain uniform particle size of 5-10 mm and pumped into suitable-capacity anaerobic digesters where stabilisation of organic waste takes place.

In anaerobic digestion, organic material is converted to biogas by a series of bacteria groups into methane and carbon dioxide. The majority of commercially operating digesters are plug flow and complete-mix reactors operating at mesophilic temperatures. The type of digester used varies with the consistency and solids content of the feedstock, with capital investment factors and with the primary purpose of digestion. via via Description BPP

In anaerobic digestion, organic material is converted to biogas by a series of bacteria groups into methane and carbon dioxide. The majority of commercially operating digesters are plug flow and complete-mix reactors operating at mesophilic temperatures. The type of digester used varies with the consistency and solids content of the feedstock, with capital investment factors and with the primary purpose of digestion. via via Description BPP

In case you don't have biological waste, you can grow energy crops for biogas production like corn, rosinweed, sweet sorghum, sugarbeat or algae. Also a biogas plant can be used as separate [stand alone] business [based upon] on waste recycling and energy production.

The following company types can consider successfully running a biogas power plant:

Agricultural companies

- Pig farms

- Cattle farms

- Poultry farms

- Crop production companies

- Bio-diesel Producers

- Waste recycling enterprises

- Municipal waste water treatment plants.

Food Industry companies

- Sugar mill

- Distillery and bio-ethanol plants

- Brewery plants

- Dairy industries

- Bakeries

- Winery … via BPP Turnkey

What is the expected cost of installing a biogas power plant

The production costs of biogas plants are determined by the following factors

- purchasing costs or opportunity costs for land which is needed for the biogas plant and slurry storage;

- model of the biogas plant;

- size and dimensions of the biogas unit

- amount and prices of material

- labour input and wages

- the degree of participation of the future biogas user and his opportunity costs for labor.

Calculating total production cost

To gain a rough idea of the typical costs of a simple, unheated biogas plant, the following figures can be used: total cost for a biogas plant, including all essential installations but not including land, is between 50-75 US Dollar per m3 capacity. 35 – 40% of the total costs are for the digester.

The specific cost of gas production in community plants or large plants is generally lower compared with small family plants. The cost for the gas distribution (mainly piping) usually increases with the size of the plant. For communal plants with several end-users of biogas, the piping costs are high and compensate the degression by ‘economics of size' partly or wholly. In regions where plant heating is necessary, large-scale plants would be more economical .

To keep the construction costs low, labour provided by the future biogas users is desirable. Often, the whole excavation work is done without hired labor. On the whole, a reduction of up to 15% of the wages can be effected by user-labour. If periods of low farm activities are chosen for the construction of the biogas plant, opportunity costs for labor can be kept low.

The operation and maintenance costs consist of wage and material cost for:

- acquisition (purchase, collection and transportation) of the substrate;

- water supply for cleaning the stable and mixing the substrate;

- feeding and operating of the plant;

- supervision, maintenance and repair of the plant;

- storage and disposal of the slurry;

- gas distribution and utilization;

- administration.

The running costs of a biogas plant with a professional management are just as important as the construction costs, for example for operation, maintenance, expenses for painting, service and repair. … via energypedia.info

Project Report: How a NY Biogas Power Plant Turns Waste Into Electricity

John Noble’s family has farmed the quilt of green fields and rolling hills around Covington in western New York for five generations. Every day, Noble’s herd of 2,000 dairy cows produce 20,000 gallons of milk, which he sells to local yogurt and cheese factories. But starting this year, he’s tapped another bovine asset, liquid cow manure.

Noble’s farm, Synergy Dairy, teamed up with the renewable energy company CH4 Biogas, which built on his property the largest on-farm biogas power plant in New York. That’s a big deal when you consider that the state is the country’s third largest milk producer.

The plant’s innovative “digestion” technology blends cow manure with cheese whey, school lunch leftovers and other food waste to make methane, and turns it into electricity in GE’s clean-burning Jenbacher engine. “It’s a commercial grade stomach,” says Lauren Toretta, vice president of CH4 Biogas.

“collect liquid food waste like whey from nearby dairy plants”

Trucks collect liquid food waste like whey from nearby dairy plants, and oils and fats from bakeries and food manufacturers as far as Rochester, some 60 miles away, while workers at the farm pump manure from Noble’s cow barns. They transfer the slush into a large receiving tank, macerate it to gain even consistency, and pasteurize it. “The pasteurization step is unique,” Toretta says, speaking like the Harvard MBA and former McKinsey & Co management consultant that she is. “It kills the pathogens that come in through the waste. We then put in the right bacteria to do its job and maximize gas output.”

Pumps push the mix into a looming 120,000-gallon digester, where it sits for three weeks as Toretta’s “good” microbes do their work and break grease, fats, and proteins into bubbles of methane in a process called “anaerobic digestion.” The gas then flows through a scrubber, which removes hydrogen and other impurities, warms up in a heater, and pools inside a compressor.

“You want the gas to come out evenly,”

Toretta explains the steps.

“ You want an even output of electricity and temperature and pressure affect the gas throughput.”

Turning the pressurized methane into a steady flow of electric power is where GE’secomagination-qualified Jenbacher engine comes in. It is designed to run around the clock with as much as 95 percent up-time. Unlike wind or solar plants, the electricity generated by the methane-fired Jenbacher is so stable and reliable that it can be fed directly to the grid.

“We run all the time, which is one of the reasons why other farms like us and the utilities like us,”

Toretta says.

“They rely on us.”

The biogas plant started generating electricity in December. It produces some 10,000 megawatt-hours of renewable electricity annually, enough to power almost 1,000 homes. The project received $1 million in funding from the New York State Research and Development Authority (NYSERDA) and another $750,000 in a grant from the National Grid utility company. …via NY Biogas

Design of Biogas Power Plants pdf

Biogas can be obtained from any organic materials after anaerobic digestion, there is a design for a biogas power plant at the link which follows at the end of this paragraph specifically, this biogas power plant design is for the construction of a buried community biogas power plant. via sswm.info

Biogas Power Plant Generator and Its Use in Co-generation Heat Power Plants

Production of electric and heat power on the bases of reciprocating engine is the main benefit of biogas. Electricity can be used all year round for the owners business needs or sold to the national grid.

Production of electric and heat power on the bases of reciprocating engine is the main benefit of biogas. Electricity can be used all year round for the owners business needs or sold to the national grid.

1 m3 of biogas can simultaneously produce 2,2 kWh of electricity and 2,2 kWh of heat power. Advantages of co-generators to be compared to analogs are following:

– oil change at 2000 operational hours but not at 500 hours.

– high electric efficiency up to 42,2%, total efficiency electricity+heat up to 90%

– high reliability

Co-generator is the main part of the biogas plant and has most of moving parts. … via ZorgCo-generation

Biogas Power Plant Manufacturers in India

Synod Bioscience, a leader in pioneering waste management systems, has been at the forefront of developing and implementing path-breaking innovative waste management solutions for residential and commercial properties.

Our product portfolio comprises domestic and commercial biogas plants, sewage treatment plants, and effluent treatment plants that have already been implemented in properties all over India. … via ManufacturersIndia

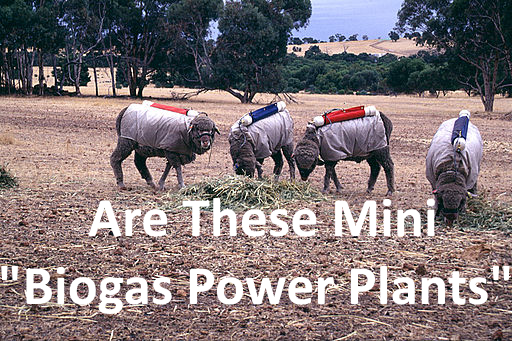

Attribution: Biogas Sheep image – CSIRO [CC BY 3.0], via Wikimedia Commons, Biogas Plant across river/ water – By Andreas Lakso (Own work) [CC BY-SA 4.0], via Wikimedia Commons

Sound arguments. Keep up the amazing work. What do you think of this – The Gorge Farm Energy Park in Naivasha produces 2 megawatts (MW) of electricity – more than enough to cultivate its 706 hectares (1,740 acres) of vegetables and flowers, and with sufficient surplus to meet the power needs of 5,000-6,000 rural homes.

The new plant generates not only electricity, but also heat for the farm’s greenhouses, with fertiliser as a by-product.

Caterpiller Ring Power makes the generator units in the US.

In Denmark we have many biogas plants. We know about them, but in the UK this is news? Surely awesome writing you have shared with your audience.

Trucks can run off biogas if you upgrade them for it. They can make liquid natural gas for the trucks. Keep functioning, terrific job!

Biogas power is expensive! How long before yo realise that your biogas will never make enough power to have the needed effect? The quick glance of your website is good. But why this biogas powering when we will have electric cars?

With this mindset, you should never have been on this platform.

I really like your way of blogging. Thanks for sharing knowledge. I urgently need to read a page about producing a biogas from animal waste (birds poultry) and using it for generating heat for the birds for 4 months.

I made my own biogas directly in my own home, using a tiny biogas system that I built for very little money. I really use the biogas to power two tiny motors in my house.