Anaerobic digestion of bioplastics, enhancing their degradation through anaerobic digestion is becoming a more important topic almost daily as EU nations move to bioplastic (biologically sourced plastic) and away from fossil fuel (oil) based plastics.

Every day, we see more plastic waste piling up in our environment. It's a big issue that affects our planet. To tackle this, scientists came up with biodegradable plastics. These materials can break down over time and that should theoretically reduce plastic pollution.

But there's a catch – they usually need specific conditions to degrade efficiently.

One effective method to speed up the breakdown of these eco-friendly plastics is through anaerobic digestion. This natural process uses microbes to turn organic wastes, including biodegradable polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), into biogas and other useful products.

This helps manage waste better and means less pollution for our environment. 1

In this blog post, we'll explore how enhancing the degradation of bioplastics via anaerobic digestion can be a game-changer in managing plastic waste. We’ll look at the benefits and some latest advancements making this process even more effective.

Get ready for an interesting read ahead!

Key Takeaways for Enhancing Bioplastic Degradation Through Anaerobic Digestion

- Anaerobic digestion breaks down bioplastics with the help of microbes and without oxygen. This process turns waste into biogas, which can be used as renewable energy, and a nutrient-rich material called digestate.

- Scientists are exploring pre-treatment methods like alkali, thermal, and thermo-alkaline treatments to make bioplastics break down faster in anaerobic digesters. Mixing these plastics with other organic wastes through co-digestion also speeds up their degradation.

- Researchers around the world are studying how to improve this method. They want to find better ways to turn more types of bioplastics into useful things faster.

- Some challenges need solving for this technology to work better, including setting worldwide standards for what counts as biodegradable plastic in anaerobic systems.

Understanding Bioplastics

Bioplastics are a type of plastic derived from renewable biomass sources. They can be biodegradable or non-biodegradable and are classified based on their origin, such as bio-based polymer, biobased plastics, and polymeric chain.

Definitions and Classification

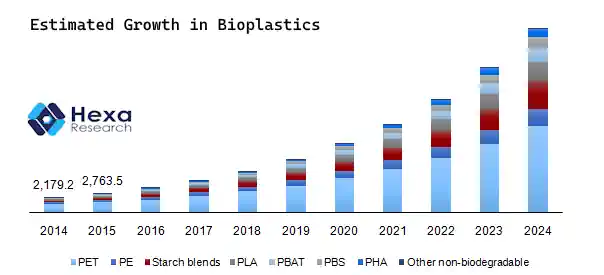

Bioplastics currently make up 1% of global plastic production, hitting over 2 million tonnes per year. That's not that much now, but the quantity is due to increase rapidly, due to public demands and government policies.

These plastics fall into three key groups. First, drop-in plastics like bio-ethylene and bio-polyethylene terephthalate (bio-PET) are made from renewable resources but are not biodegradable.

Second, fossil-based plastics include materials such as polycaprolactone (PCL) and polybutylene succinate (PBS), which may degrade under certain conditions. Lastly, the group of bio-based and biodegradable plastics consists of polylactic acid (PLA) and polyhydroxyalkanoates (PHAs).

These break down more easily in the environment. 1

Each type serves different needs in waste management and environmental protection. Drop-in bioplastics replace conventional ones without changing existing recycling processes. Fossil-based options show how traditional petroleum products can evolve to more sustainable versions with some degradability features.

Meanwhile, fully biodegradable polymers like PLA offer new ways to reduce waste through composting or anaerobic digestion. 2 Next, we examine how these materials break down in nature.

Different types of biodegradable bioplastics

Biodegradable bioplastics offer a promising solution to reduce plastic pollution and move towards a circular economy. These materials break down into natural substances like water, carbon dioxide, and compost through microbial action. Here's a look at some key types:

- Polylactic Acid (PLA): Made from fermented plant starch, PLA is one of the most common types of biodegradable plastics. It's used in packaging, disposable cutlery, and even medical devices. This biopolymer degrades into lactic acid when exposed to the right conditions in an industrial composting facility. 3

- Polyhydroxyalkanoates (PHAs): PHAs are produced by bacteria when they consume sugar or lipids under stress conditions. This family of biopolymers is both bio-based and fully biodegradable in various environments, including marine, making it ideal for reducing microplastic pollution.

- Polybutylene Succinate (PBS): Derived from succinic acid and 1,4-butanediol, PBS is known for its heat resistance and toughness. It breaks down in composting conditions and is often used in agriculture for mulch films as well as food packaging applications. 2

- Polybutylene Adipate Terephthalate (PBAT): PBAT is a flexible and biodegradable polyester that degrades quickly under composting conditions. It's commonly blended with other bioplastics to improve their mechanical properties and is used in bags for collecting organic waste.

- Polycaprolactone (PCL): PCL is synthesised from petroleum sources but stands out due to its low melting point and ease of processing. It’s compostable under industrial setups and finds applications in speciality areas such as biomedical devices due to its compatibility with human tissue.

Using these materials helps shift away from reliance on fossil fuels for plastic production and supports energy recovery through anaerobic digestion processes that turn waste into valuable resources like biogas and biomethane. Each type of bioplastic offers distinct advantages depending on its application, contributing significantly to environmental sustainability efforts.

Table of bioplastic compounds with their fossil-based alternatives:

| Bioplastic Compound | Fossil-Based Alternative | Features | Advantages | Disadvantages |

|---|---|---|---|---|

| Polylactic Acid (PLA) | Polystyrene (PS) | Made from corn starch or sugarcane; compostable under industrial conditions | Renewable source, compostable (industrially), good clarity | Lower heat resistance, brittle, not always biodegradable in home composts |

| Cellulose Acetate (CA) | Polyethylene Terephthalate (PET) | Derived from wood pulp; biodegradable | Biodegradable, good moisture barrier | Lower heat resistance, absorbs moisture |

| Polyhydroxyalkanoates (PHAs) | Produced by microorganisms from bacteria; biodegradable | Biodegradable under various conditions, versatile | Lower production rate, expensive | |

| Starch-Based Bioplastics | High-Density Polyethylene (HDPE) | Made from starches like corn or potato | Renewable source, good for packaging | Lower strength, moisture sensitive |

Note:

- This table provides a general comparison, and specific properties may vary depending on the type of bioplastic and fossil-based plastic.

- Be sure to check with the bioplastic manufacturer for specific information on their products.

Biodegradation mechanisms

Biodegradation turns bioplastics into water, biomass cells, and gases like CO2 or CH4. This process starts with biodeterioration where the plastic's surface begins to break down. Then, depolymerisation takes over, slicing the long polymer chains into smaller pieces.

Microbes eat these pieces during assimilation and finally change them into simple molecules through mineralisation. Over 90 types of microbes are hard at work in this process. They mostly come from places such as when mixed with compost, in an anaerobic digester, or the soil. 4

In my work on anaerobic digestion plants, I've seen how these steps play out firsthand.

I'd say that:

Biodeterioration makes the plastic weak; depolymerisation chops it up; assimilation means microbes feast on what’s left; then mineralisation cleans up the rest.

Each phase is crucial for turning what once was pollution back into natural elements. 2

Anaerobic Digestion: Process and Benefits for Enhancing Bioplastic Degradation Through Anaerobic Digestion

Anaerobic digestion is a natural process where microorganisms break down biodegradable material in the absence of oxygen. This process produces biogas, which can be used as a renewable energy source, and also reduces the volume of waste that would otherwise require disposal.

Definition and explanation of using the AD process for enhancing bioplastic degradation through anaerobic digestion

Anaerobic digestion (AD) is a process that turns waste into energy and helps break down bioplastics. It does this without using oxygen. This method uses microorganisms to transform biodegradable materials in environments lacking air, producing biogas and digestate as outputs.

Biogas can be used for energy production, while digestate is a nutrient-rich substance beneficial for soil. AD is particularly important for tackling the issue of bioplastic degradation in soil, enhancing both waste management and renewable energy sources. 1

This process shines in managing municipal solid waste and sewage sludge, including biodegradable plastics like SB (Starch Based) bioplastics and poly(lactic acid) or PLA. Research shows that thermophilic AD (a type of AD done at high temperatures) can degrade SB bioplastics by 50% and PLA by up to 70%.

Such efficient degradation rates make AD vital in the production of biomethane from bio-based plastics while ensuring the resulting digestate maintains quality standards for use in agriculture or landscaping.

Next, we’ll explore how anaerobic digestion applies specifically to degrading different types of bioplastics. 2

How it can be used for bioplastics degradation

Moving from understanding the basics, we see that anaerobic digestion plays a crucial role in breaking down bioplastics. This process happens without oxygen and turns waste into biogas and other useful by-products.

It offers a smart solution to manage compostable plastics, turning them into something valuable. Studies show promising results: thermophilic treatments can degrade up to 70% of PLA (polylactides) and 50% of SB (a type of bioplastic) materials.

This means we can significantly reduce the amount of plastic waste by using this technology. 1

Experts often highlight the importance of pre-treatment technologies like alkali or thermal processes to boost gas production from these plastics. By applying these methods before digestion, we ensure that more material breaks down faster, increasing the efficiency of methane production.

Moreover, combining bioplastics with other organic wastes through co-digestion enriches microbial communities in digesters, further enhancing degradation rates. Yet, it's essential to consider how left-over materials from digestion impact soil health if they're applied as an amendment. 2

Advantages over other waste management methods

Anaerobic digestion stands out from other waste management practices such as incineration and landfilling. This method uses microorganisms to break down organic waste of all sorts and this includes bioplastics in the absence of oxygen.

It turns this waste into biogas, a renewable energy source, and digestate, a nutrient-rich material that can help plants grow. Unlike burning trash, which releases harmful greenhouse gases (GHGs), anaerobic digestion cuts down on pollutants. 2 It also makes good use of organic materials that might otherwise fill up landfills or turn into microplastics that harm our environment.

This process provides an effective solution for managing starch-based bioplastics and PLA by transforming them into useful resources rather than letting them degrade over decades. 1 In countries like Italy, laws now demand organic waste undergo this kind of processing at industrial composting facilities or through anaerobic degradation.

Such regulations highlight the global move towards sustainable practices that not only reduce environmental pollution but also supply green energy options and reuse opportunities for what was once considered waste.

Turning our attention to enhancing the efficiency of bioplastic degradation leads us to explore various pre-treatment methods and co-digestion techniques next.

Methods for Enhancing Bioplastic Degradation

Enhancing bioplastic degradation involves pre-treatment options such as alkali, thermal, and thermo-alkali treatments. Co-digestion with other organic waste can also boost the process, while factors affecting degradation must be considered.

For a more comprehensive understanding of these methods, delve deeper into our blog post below!

Pre-treatment options (alkali, thermal, thermo-alkali)

Pre-treatment methods can make bioplastics break down faster in anaerobic digesters. These processes turn difficult-to-digest bioplastics into a form that microbes can easily tackle.

- Alkali pre-treatment uses strong alkaline substances like potassium hydroxide (KOH). Treating bioplastics with 4 M KOH for 48 hours at 35°C has shown success. This method breaks down the complex chains in polymers, making it easier for bacteria to feed on the material during anaerobic digestion. 6

- Thermal pre-treatment involves heating the bioplastic materials. This heat changes the structure of bioplastics, making them softer and more accessible for microorganisms. When combined with other methods, thermal treatment significantly speeds up degradation.

- Thermo-alkaline pre-treatment is a mix of high heat and alkaline chemicals. For certain types of biodegradable plastics, this combination not only makes them break down faster but also increases methane production during the process. It proves especially effective under specific conditions appropriate for each type of bioplastic.

Pre-treating materials brings us a step closer to turning them into bioenergy or compost instead of taking up space in landfills. Through these improved methods, we can enhance how quickly and efficiently bioplastics return to nature. 5

Co-digestion with other organic waste

Co-digestion with other organic waste is a crucial strategy for enhancing bioplastic degradation and improving biogas production during anaerobic digestion.

- Mixing bioplastics with organic waste such as food waste or bio-waste optimises the anaerobic digestion process, leading to nominally increased biogas yields. 7

- The co-digestion of bioplastics with bio-waste streamlines the waste management system and promotes sustainable practices in the treatment of organic waste. 7

- This method reduces the chemical oxygen demand (COD) of the mixed substrate, enhancing the efficiency of anaerobic digestion processes.

- Co-digestion can significantly boost the degradation rates of biodegradable polyesters and other bioplastics, contributing to a more effective waste management solution.

- Researchers have demonstrated that co-digestion with organic waste diversifies the microbial community within anaerobic digesters, enhancing overall process stability and performance.

By leveraging co-digestion strategies, environmental researchers, waste management professionals, and government officials can effectively address the challenges associated with bioplastic degradation and contribute to sustainable waste management practices. 1

Factors that affect degradation

Factors that influence the degradation of bioplastics are critical for understanding their behaviour in anaerobic digestion. Here are some key factors to consider:

- Biotic and abiotic factors, such as temperature, pH, and biomass concentration, play a significant role in bioplastic degradation. 8

- The nature of the polymer itself, including its chemical structure and molecular weight distribution, directly impacts its biodegradability.

- Pretreatments aimed at disrupting macromolecular aggregate structures can facilitate biodeterioration and subsequent microbial degradation.

- The carbon to nitrogen (C/N) ratio of bioplastics presents a challenge and often requires co-digestion with lower C/N ratio biowastes to enhance degradation efficiency. 2

These factors collectively contribute to the complex process of enhancing bioplastic degradation through anaerobic digestion.

Research and Future Directions

- Advancements in using anaerobic digestion for bioplastics

- Future avenues for research and development within this field.

Latest advancements in anaerobic digestion of bioplastics

Recent studies have revealed a surge in scientific interest in the anaerobic digestion of bioplastics. Over the past five years, there has been a notable increase in research, particularly from countries such as the USA, Italy, Japan, China, and Germany.

A total of 179 studies on anaerobic degradability were analysed, with PHAs, PLA and PLA blends/co-polymers, and starch-based polymers emerging as the most widely investigated biopolymers.

The publication period covered ranges from 1992 to early 2023. 9

An extensive analysis reports that these studies primarily originate from main research fields including environmental science and engineering, (micro)biology, biochemistry, biotechnology, and polymer/materials science.

Furthermore, an examination reveals that while mesophilic conditions accounted for 120 publications on the topic of anaerobic degradability; thermophilic conditions were explored in 59 instances across research literature up until early 2023. 2

Areas for further research and development

Future directions in the field of bioplastic degradation through anaerobic digestion should focus on establishing universal standards and certifications for the biodegradability of plastics within anaerobic digestion systems.

This necessitates further exploration to enhance the rate of biodegradation, specifically examining methods such as pre-treatment options like alkali, thermal, and thermo-alkali treatments.

Additionally, extensive research is required to evaluate the impact of anaerobic digestion on the quality and safety of the resulting digestate. 10

Furthermore, it is crucial to address technical, environmental, and societal challenges hindering the development of AD plants for the treatment of biodegradable plastics in anaerobic digestion processes. The potential formation and environmental implications of micro-biodegradable plastics (MBPs) demand focused attention; thus, in-depth research into their fate and impacts is imperative.

All these areas warrant a thorough investigation by environmental researchers, waste management professionals, and government officials to advance sustainable waste management practices. 11

Conclusion to the Anaerobic Digestion of Bioplastics

In conclusion, anaerobic digestion offers practical and efficient solutions for enhancing bioplastic degradation. Have you considered implementing pre-treatment options to accelerate the biodegradation of bioplastics? How important do you think it is to harmonise international certifications for biodegradable plastics? By leveraging the potential of anaerobic digestion, we can significantly reduce plastic waste pollution and enhance energy recovery.

Imagine the impact of the widespread adoption of enhanced anaerobic degradation methods! Let's inspire change in waste management practices and embrace a sustainable future together.

FAQs about the Anaerobic Digestion of Bioplastics

1. What is anaerobic digestion?

Anaerobic digestion is a process that breaks down materials in the absence of oxygen. It involves stages like acidogenesis and acetogenesis, where bacteria turn waste into gas and other products.

2. Can bioplastics be broken down during the anaerobic digestion of bioplastics this way?

Yes, certain bioplastics can degrade anaerobically. Biodegradable plastics like PHA and PBAT are good examples that can break down in these conditions.

3. How does anaerobic co-digestion work for bioplastics?

In anaerobic co-digestion, bioplastics are mixed with other organic wastes, which helps speed up their breakdown. This method uses natural processes to turn bioplastics into useful products like methane.

4. Are all bioplastics suitable for this process?

Not all but many types, especially those designed to be bio-based or oxo-degradable, can undergo degradation through this method effectively.

5. What role do microbes play in breaking down bioplastic?

Microbes such as methanogens play a crucial role during fermentation by digesting the material and producing methane as one of the outputs.

6. How do scientists study the breakdown of bioplastic under these conditions?

Scientists use tools like spectroscopic analysis to understand how different types of plastic degrade over time anaerobically They look at chemical shifts using NMR spectra technology to see how materials change at a molecular level.

References to Anaerobic Digestion of Bioplastics

- ^ https://www.sciencedirect.com/science/article/abs/pii/S0921344922005274

- ^ https://www.ncbi.nlm.nih.gov/pmc/articles/PMC10058929/

- ^ https://www.mdpi.com/2073-4344/13/2/294

- ^ https://www.sciencedirect.com/science/article/abs/pii/S0959652622028190

- ^ https://www.researchgate.net/publication/361821223_Enhancing_the_biodegradation_of_bioplastic_through_pretreatments_A_critical_review (2022-11-11)

- ^ https://pubmed.ncbi.nlm.nih.gov/38754301/

- ^ https://www.sciencedirect.com/science/article/abs/pii/S0960852420318113

- ^ https://www.sciencedirect.com/science/article/abs/pii/S0956053X22003038

- ^ https://www.researchgate.net/publication/357824810_Degradability_of_bioplastics_in_anaerobic_digestion_systems_and_their_effects_on_biogas_production_a_review

- ^ https://www.sciencedirect.com/science/article/abs/pii/S073497502200012X

- ^ https://www.researchgate.net/publication/341562698_Biodegradation_of_Bioplastic_Using_Anaerobic_Digestion_at_Retention_Time_as_per_Industrial_Biogas_Plant_and_International_Norms (2020-05-19)