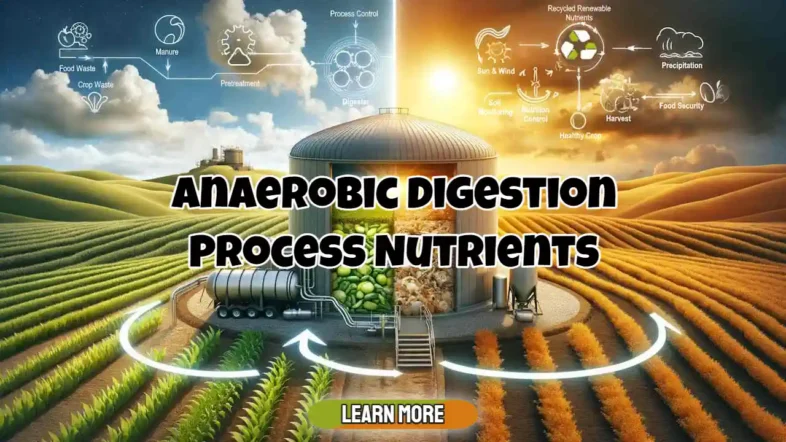

Anaerobic Digestion Process Nutrients: Ensuring the Right Conditions for Successful Anaerobic Digestion

The balance of nutrients is crucial to all biological processes.

If any nutrient is absent or in low supply, it may become process rate-limiting. In some cases, the lack of particular nutrients may reduce the stability of biological processes, or result in organisms being present in the biomass that are inefficient for the process, or to the detriment of the process, and proper treatment.

Of course, any reduction in the rate of methane production has serious consequences for plant throughput and economic operation, so these considerations are very important.

Introduction to Anaerobic Digestion Process Nutrients

There are normally considered to be two types of nutrients in biological systems:

- major nutrients, of which quite large quantities are needed, and

- micronutrients, which need to be present at much lower levels but, if absent, can be equally important.

The major nutrients required by the bacteria are ammonium and phosphate. The optimum range is, typically reported to be around 5 kg per tonne of organic matter for nitrogen, and 1 kg of phosphorus per tonne of organic matter destroyed.

There are normally plenty of proteins present from the decomposition of household waste, so there is not usually a shortage of ammonium ions, but some additional phosphate may be required to ensure optimum process rates.

The micro-nutrients that methane bacteria require in trace quantities include iron, manganese, copper, nickel, zinc, and cobalt, all of which are likely to be present in MSW.

Although MSW may contain toxic metals that are not needed in any quantity at all, including cadmium, chromium, mercury and lead. The bacteria tend to be protected from excessive concentrations of these metal salts by the action of sulphate-reducing bacteria which tend to precipitate “surplus” metal ions as their insoluble sulphide salts.

If required, sewage sludges and animal slurries can be added to the feedstock to provide a useful source of all the “major and micro” nutrients required by the anaerobic digestion bacteria.

Anaerobic Digestion Process Nutrients Essentials

pH and Alkalinity

pH and alkalinity are closely linked. As alkalinity drops, the pH will also fall.

Methane bacteria will grow at all pH values between 6.0 and 8.5 with an optimum slightly above pH 7.0. A minimum alkalinity of about 500 mg/l is required to neutralise the acidity of the dissolved carbon dioxide gas and to form a buffer within the optimum pH range.

Higher alkalinities are sometimes helpful, especially during start-up, to neutralise the initial acidity of a higher-than-normal level of volatile fatty acids, until the contents of the reactor “age”.

Ammoniacal nitrogen, which results from cell lysis (the breakdown of cell proteins), is a significant source of alkalinity in MSW. The concentrations of ammoniacal nitrogen are high and often in the 1000-4000 mg/l NH4N range. The release results in pH values in the range 7.5-8.5, which is naturally suitable for the fermentation process.

Salts and Salinity

In general, the methane bacteria that live in sludge digesters and landfills are likely to be from freshwater species. This means that they can only handle a certain amount of high salinity buildup in the added process water if it is circulated too many times.

Optimum and inhibitory concentrations of some common salts are reported by McCarty, (1964) (see our references page).

There are also calcium and magnesium salts in the MSW, but they probably will not stop the bacteria because their solubility limits their maximum concentrations, and they tend to settle out before they reach concentrations that stop the bacteria.

Rate of Reaction

Overall reaction rates and, hence, plant throughput can only proceed at the pace of the slowest in the chain.

Reaction rates are generally limited by the slow growth of the methanogens – those “methane bacteria” that convert acetic acid to carbon dioxide and methane.

Optimum Temperature, and the Selection of Either a Mesophilic or Thermophilic Reaction Temperature

Both mesophilic and thermophilic strains of methane bacteria can be used in anaerobic digestion processes.

Mesophilic methane bacteria grow best at 35-40°C, and thermophilic methane bacteria grow best at 55-60°C.

Most anaerobic digestion plants work best at mesophilic temperatures between 3°C and 35°C so they do not have to heat the reactor. The material needs to stay in the reactor for 15 to 20 days on average to produce a good amount of methane gas and a good digestate product.

The thermophilic reaction rate can be more than double the mesophilic rate, in theory, so it may be chosen to reduce vessel size.

Traditional anaerobic digestion for sewage sludge treatment has most often used the mesophilic range. However, there has been a trend for the high solids contents available from MSW to use the more rapid (10 to 15 days) fermentation at thermophilic temperatures of 55°C to 60°C. The reduction in reactor size may be attractive, especially if the plant includes a CHP provision, as the waste heat from the utilisation of the methane, can then be used to heat the reactor.

The temperature attained during thermophilic conditions provides much better sterilisation of weed seeds and possibly also of “pathogens.”

In countries that have regulations that seek to ensure biological security (e.g., the prevention of the spread of such vectors as the “foot and mouth” disease in cattle), higher temperatures than in the mesophilic process are required for sanitisation.

In such regulations as the EU’s Animal By-Products (ABPR) regulations, the thermophilic choice, if well controlled, can, with the attainment of the top temperature demonstrated by monitoring, provide intrinsic compliance.

This should be compared with the mesophilic process choice, which will always require an additional stage of separate pasteurization of the liquid (fertilizer), and possibly also of the solid by-products.

Disclaimer: The contents provided here are for general reading purposes. None of the statements made on this website are intended for plant design or for making investment decisions. In the event of commercial use of this nature, the website reader shall always obtain professional advice.

[Anaerobic Digestion Process Nutrients – Originally published: November 13, 2014. ][Updated March 2024.]

I would just like to point out that although gas production and “energy potential” typically dominate the thinking in the anaerobic digestion techn world today. This emphasis may, in the future, look incredibly naive, while benefits of residues and nutrient management from AD are ignored.

Do you not think, making best use of AD residues should be a priority right now? For example, the value of properly managing nutrients, such as phosphorus, can easily make-or-break projects. They should not be discarded as being uneconomical, based on energy production value alone.

Adding the right nutrients as needed is a high skill. Choose a company working with owners and operators as they manage and maximise energy production. There is no doubt that attention to nutrients pays-off, and solutions should be easy to administer, cost-effective and lead to optimal output.

Kemira’s patented technology, Kemira BDP, will boost your biogas production significantly by improving the efficiency of the methane-forming bacteria. The organisms responsible for the final methane-producing step are slow growing and sensitive, needing a specific set of conditions and micronutrients to perform optimally. The BDP treatment increases the amount of methane-forming bacteria, creates a more stable process and reduces the H2S level, which allows an increase in digester load as well as improving biogas yield. Kemira Biogas boosting.

Anyone here know a good lab which knows how to interpret nutrient requirements from chemical analysis reports? Keep up the good work on this website.

My biogas system is just starting to produce an output from my digester. I am told it must be watered down before using it as fertiliser for my garden. But by how much should I water it down? Nobody seems to be telling me when I spend my time looking.