Just what is biogas?

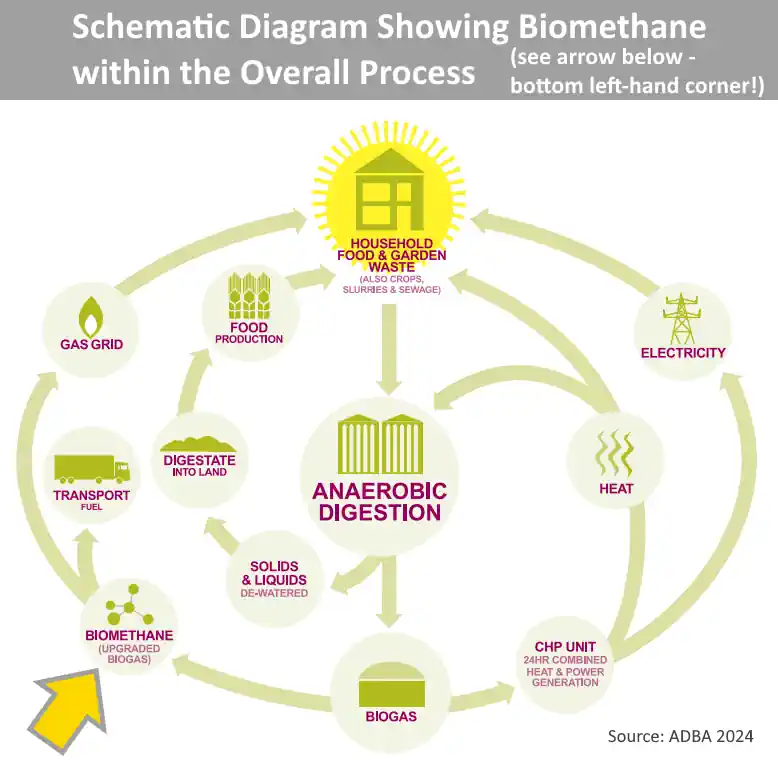

Biogas is a renewable energy source generated through the anaerobic digestion of organic materials such as agricultural waste, manure, municipal sewage sludge, plant material, and food waste. This natural process breaks down organic matter in the absence of oxygen, producing a gaseous mixture primarily composed of methane (CH₄) and carbon dioxide (CO₂), with trace amounts of other gases. Biogas (also known as bio gas) serves as a sustainable alternative to fossil fuels, offering both energy generation and waste management solutions.

The Process of Anaerobic Digestion

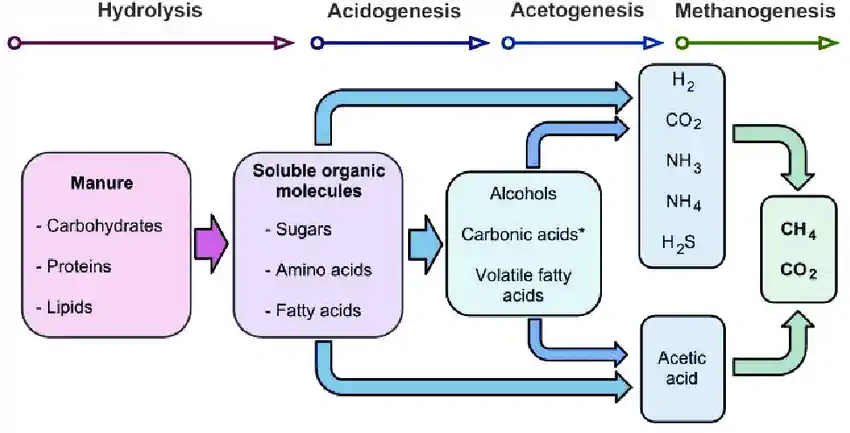

Anaerobic digestion is the core biological process underlying biogas production. It involves the decomposition of organic materials by microorganisms in an oxygen-free environment. This process occurs in several stages:

- Hydrolysis: Complex organic polymers, such as carbohydrates, fats, and proteins, are broken down into simpler soluble compounds like sugars, fatty acids, and amino acids by hydrolytic bacteria.

- Acidogenesis: The simple molecules produced during hydrolysis are further metabolized by acidogenic bacteria to form volatile fatty acids, alcohols, hydrogen, and carbon dioxide.

- Acetogenesis: Acetogenic bacteria convert the products of acidogenesis into acetic acid, additional hydrogen, and more carbon dioxide.

- Methanogenesis: Methanogenic archaea convert the intermediates produced during acetogenesis into methane and carbon dioxide, completing the biogas.

This multi-step process occurs within anaerobic digesters—sealed, oxygen-free containers where temperature and pH are carefully controlled to optimize microbial activity.

Types of Anaerobic Digesters

Several types of anaerobic digesters are utilized in biogas production, each tailored to specific feedstocks and operational requirements:

- Mesophilic Digesters: Operate at moderate temperatures, typically between 30°C and 40°C. They are widely used due to their stability and lower energy requirements.

- Thermophilic Digesters: Operate at higher temperatures, around 50°C to 60°C. They offer faster digestion rates and higher pathogen reduction but require more energy input for heating.

- Plug Flow Digesters: Designed for high-solids feedstocks, facilitating the movement of material through the digester as a plug.

- Continuous Stirred-Tank Reactors (CSTRs): Provide thorough mixing of the substrate, ideal for liquid or slurry feedstocks.

Methane Production from Organic Waste

Methane is the primary component of biogas, typically comprising 50% to 70% of the gas mixture. The production of methane from organic waste involves the efficient conversion of biodegradable materials through anaerobic digestion. Key factors influencing methane yield include:

- Feedstock Composition: The type and proportion of organic matter significantly impact biogas and methane production. High-moisture, carbohydrate-rich materials tend to produce more gas.

- Retention Time: The duration organic materials remain in the digester affects the extent of digestion and methane yield. Longer retention times allow for more complete breakdown.

- Temperature Control: Maintaining optimal temperatures is crucial for maximizing microbial activity and methane production. Mesophilic and thermophilic conditions cater to different microbial communities.

- pH Levels: A stable pH environment, typically between 6.8 and 7.4, is essential for methanogenic bacteria to thrive and produce methane efficiently.

- C:N Ratio: The carbon to nitrogen ratio of the feedstock influences microbial balance and digestion efficiency. An ideal C:N ratio fosters optimal microbial growth and methane production.

Energy Production and Combined Heat and Power (CHP)

Biogas can be harnessed as a versatile energy source through various conversion technologies. One of the most effective methods is Combined Heat and Power (CHP) systems, which simultaneously generate electricity and useful heat from this gas.

Electricity Generation

Biogas-powered generators or engines convert methane into electricity through combustion. These systems can range from small-scale units suitable for individual farms or businesses to large-scale installations capable of supplying power to entire communities or industrial facilities.

Heat Production

The heat generated from biogas combustion can be utilized for:

- Process Heating: Providing thermal energy for industrial processes, such as drying, heating, and sterilization.

- Space Heating: Contributing to building heating systems, especially in agricultural or industrial settings.

- District Heating: Feeding heat into district heating networks to supply multiple buildings or areas.

Combined Heat and Power (CHP)

CHP systems harness the thermal energy produced alongside electricity generation from biogas, significantly improving overall energy efficiency. By utilizing both electricity and heat, CHP systems can achieve combined efficiencies of up to 80%, compared to around 50% for separate heat and power generation. This dual utilization maximizes energy output from the same amount of biogas, making CHP an economically and environmentally attractive option.

Advantages of Biogas

Biogas offers a multitude of benefits, making it a compelling choice for sustainable energy and waste management:

- Renewable Energy Source: Biogas is continually produced from organic waste, reducing dependence on finite fossil fuel resources.

- Waste Reduction: Utilizing organic waste for bio gas production mitigates landfill usage, decreases greenhouse gas emissions, and promotes circular economy principles.

- Carbon Neutrality: The carbon dioxide released during it's combustion is offset by the carbon captured during the growth of the biomass feedstock, contributing to net-zero carbon emissions.

- Energy Independence: Biogas production can bolster energy security by providing a local and decentralized energy source.

- Nutrient Recycling: The digestate, a byproduct of biogas production, is a nutrient-rich fertilizer that can be returned to agricultural fields, enhancing soil health and reducing the need for synthetic fertilizers.

- Economic Opportunities: Biogas projects create jobs in construction, operation, and maintenance, and can generate revenue through energy sales and waste management services.

Applications of Biogas

Biogas serves various applications across multiple sectors, showcasing its versatility as an energy source:

Agricultural Sector

- Farm Energy: Farmers utilize biogas to power irrigation systems, run farm equipment, and provide heating for livestock facilities.

- Waste Management: Utilizing manure and crop residues for biogas production helps manage agricultural waste sustainably.

Industrial Sector

- Process Energy: Industries can integrate biogas CHP systems to supply both electricity and heat for their operations, reducing energy costs and carbon footprint.

- Waste Treatment: Biogas production offers a sustainable method for treating organic industrial waste, enhancing overall environmental performance.

Municipal Sector

- Waste-to-Energy: Municipal solid waste, including food scraps and organic residues, can be converted into biogas, alleviating landfill burdens and generating clean energy.

- Public Infrastructure: Biogas systems can power municipal buildings, street lighting, and public transportation systems.

Residential Sector

- Biogas for Cooking and Heating: In regions where access to traditional energy sources is limited, biogas provides a clean and efficient alternative for cooking and heating.

Transportation Sector

- Bio-Methane: Upgraded biogas, known as bio-methane, can be used as a renewable natural gas (RNG) for transportation, powering vehicles with reduced greenhouse gas emissions.

Environmental Impact of Biogas

Biogas production and utilization offer significant environmental benefits, contributing to sustainability and climate objectives:

Greenhouse Gas Reduction

Biogas systems capture methane emissions from organic waste that would otherwise enter the atmosphere through decomposition or landfill. Methane is a potent greenhouse gas, with a global warming potential approximately 28 times that of carbon dioxide over a 100-year period. By harnessing methane for energy, biogas systems not only prevent its release but also substitute fossil fuel use, resulting in lower overall greenhouse gas emissions.

Renewable Energy Integration

Biogas complements other renewable energy sources, such as solar and wind, by providing a reliable and dispatchable energy supply. This enhances the stability and resilience of energy systems, particularly in regions with intermittent renewable resources.

Nutrient Management

The digestate produced during biogas production is rich in nutrients like nitrogen, phosphorus, and potassium, which are essential for plant growth. This enables the recycling of nutrients back into agricultural systems, reducing the reliance on synthetic fertilizers and promoting sustainable soil management.

Waste Management and Pollution Control

Biogas systems offer an effective solution for managing various types of organic waste, reducing the environmental impacts associated with improper disposal, such as leachate generation, odor emissions, and water contamination.

Biodiversity Conservation

By mitigating the need for landfill space and reducing pollution, biogas production supports the preservation of natural habitats and biodiversity. Sustainable waste management practices help maintain ecosystem integrity and minimize human-induced environmental degradation.

Challenges and Considerations in Biogas Production

While biogas offers substantial benefits, there are challenges and considerations to ensure its successful implementation and operation:

Feedstock Availability and Quality

Consistent and high-quality feedstock is crucial for stable biogas production. Variability in organic waste composition can affect methane yield and process stability, necessitating careful feedstock management and pre-treatment.

Technical Expertise and Management

Operating anaerobic digesters and biogas systems requires specialized technical knowledge and expertise. Effective management of the biological and mechanical components is essential to maintain system performance and longevity.

Initial Capital Investment

Biogas projects typically involve significant initial capital investment for infrastructure, equipment, and installation. Securing funding and ensuring economic viability through efficient operation and potential revenue streams are key considerations.

Regulatory and Policy Support

Supportive regulatory frameworks and incentives, such as feed-in tariffs, grants, and tax credits, are critical for the economic feasibility of biogas projects. Navigating regulatory requirements and ensuring compliance with environmental standards can also pose challenges.

Market Development for Biogas Products

Developing markets for biogas-derived products, such as bio-methane and digestate, is essential for the overall success and sustainability of bio gas systems. Establishing value chains and enhancing market acceptance are ongoing efforts.

Future Prospects of Biogas

The future of biogas is promising, driven by technological advancements, increasing renewable energy demand, and heightened environmental awareness. Key trends and prospects include:

Technological Innovations

Advancements in anaerobic digestion, biogas upgrading technologies, and energy conversion systems are enhancing the efficiency and scalability of bio gas production. Innovations such as biomethane purification and integrated energy systems are expanding biogas applications.

Integrated Renewable Energy Systems

Biogas is increasingly being integrated with other renewable energy sources and energy storage solutions, creating hybrid systems that offer enhanced reliability and flexibility. This integration supports the transition to a more sustainable and resilient energy landscape.

Policy and Regulatory Developments

Robust policies and supportive regulatory frameworks are fostering the growth of the biogas sector. International agreements on climate change and national renewable energy targets incentivize bio gas investments and facilitate market expansion.

Circular Economy and Sustainability Goals

Biogas aligns with the principles of a circular economy, promoting resource efficiency, waste minimization, and sustainable production and consumption. Its role in achieving sustainability goals positions biogas as a key component of future energy strategies.

Global Expansion and Accessibility

Biogas has significant potential for global expansion, particularly in developing regions with abundant organic waste and limited access to conventional energy sources. Efforts to enhance accessibility and affordability can drive widespread adoption and contribute to global energy sustainability.

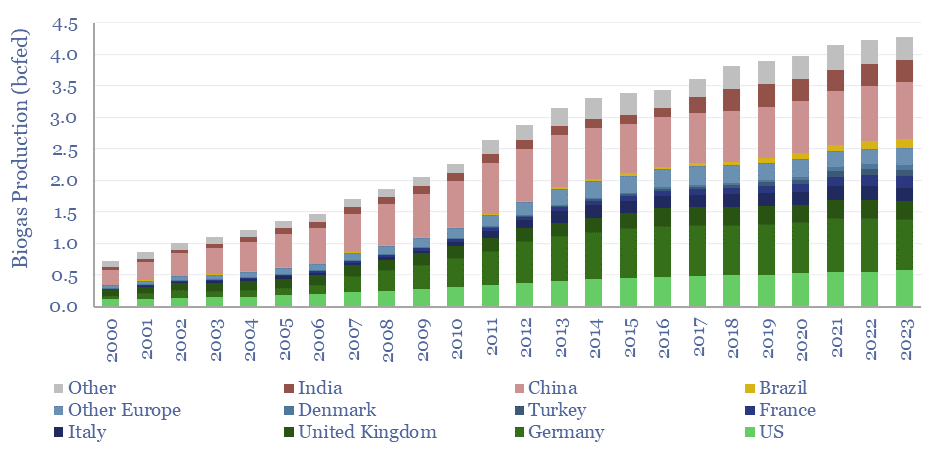

“Chart showing global growth in Biogas production by country” – Thunder …” from thundersaidenergy.com and used with no modifications.

Conclusion

Biogas stands as a versatile and sustainable energy solution, harnessing the power of anaerobic digestion to convert organic waste into methane-rich gas. Through processes like Combined Heat and Power (CHP), biogas not only generates electricity and heat but also plays a pivotal role in waste management and environmental protection. As technological innovations advance and supportive policies emerge, the biogas sector is poised for growth, contributing to a greener and more resilient energy future.

For more information on how biogas can benefit your organization or to explore biogas system installation services, contact our experts today.