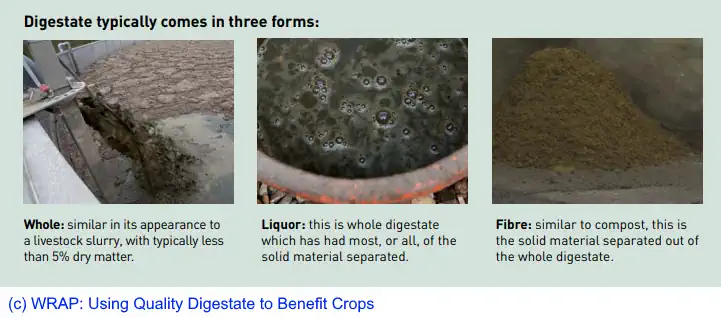

The question as to whether to go for Digestate Disposal, or use it as a Natural Fertilizer is important, and not a simple one to determine. Digestate from any wet anaerobic digestion process comprises both a liquid and a fibrous solid material.

As we plan Anaerobic Digestion Plants the question arises for each site as to whether to:

As we plan Anaerobic Digestion Plants the question arises for each site as to whether to:

- simply use the digestate by spreading it on farmland, usually without liquid/ solid separation of the slurry. If this is done on-farm in the UK, the digestate is not classed as a waste material

- dispose digestate to a landfill as waste material with the fibrous solids sent to landfill, and the liquid sent (usually by tanker vehicle) to liquid waste treatment, or

- go one step further and produce quality-controlled natural fertiliser products from the digestate.

Examples of anaerobic digestion plant types which are most likely to apply the above 3 options are:

- Agricultural biogas plants such as those operated on dairy farms and fed with manure.

- Food waste digesters not located on farm holdings and digestion plants used to process the organic fraction of mixed municipal household waste (biological municipal waste – BMW).

- Anaerobic digestion plant operators where they feed their digesters with known contaminant-free organic waste materials of high purity, such as large nurseries and catering establishments.

Opportunities for Commercial Sales of Digestate

A fertiliser product for commercial sale would be sold as:

- a liquid fertiliser or

- the composted fibrous material output from the digester.

Digestate disposal of the solid component of digestate may be sold as:

- a soil conditioner, or possibly a fibrous material which could be further processed (pressed) into blocks etc, and used in buildings.

The best digestate to process and sell as a quality-controlled fertiliser is the digestate from agricultural anaerobic digestion plants, especially those which do not accept imported feed materials. The reason is that the operator will have full control of any feedstock contaminants which may cause problems in the digestate product.

In order to sell the digestate (including agricultural digestate used off-farm) operators must comply with the relevant waste regulations in their location. In the UK the requirement is to comply with the End-of-Waste Criteria, as follows.

Digestate and the End-of-Waste Criteria

Source separation schemes are beginning to help to diminish metal contents in our domestic refuse.

Plastics are unsightly and now known to be damaging to wildlife, discouraging the use of refuse-derived digestate. Broken glass is a major hazard and greatly diminishes the possible outlets for the material.

But, with the cooperation of the public, who will probably need to be incentivised in some way as well, source separation can avoid the presence of troublesome quantities of these materials.

Digestate from Biological Municipal Waste (BMW) Digesters

Digestate from Biological Municipal Waste (BMW) digesters is unlikely to be suitable for use for spreading on land used for food crop production due to the presence of contaminants that may be hazardous or may accumulate.

The primary advantage seen by many Local Authority Waste Management Officers for the use of Anaerobic Digestion in Europe as a process applied to household waste will be for:

- compliance with the requirements for all waste to be pre-treated before disposal to landfill

- the conversion of BMW to a waste which passes the regulatory authorities requirements to allow it to be landfilled.

Composting of the fibrous material in BMW digestate will normally be required before it can be used, for non-food land application such as to restore landfill soils.

To the European Regulators implementing their waste diversion rules, the important requirement is to reduce organic waste or more precisely the landfilling of BMW.

BMW digestate is produced from the organic fraction of mixed household waste (residual or black bag waste).

Anaerobic digestion of BMW digestate with pasteurisation provides good protection against pathogens and subsequent composting of the digestate provides a further barrier to infection.

There is often sufficient waste heat available from the biogas output, for drying, and pasteurising of the product if required.

Barriers to Digestate Use as a Natural Fertilizer

The problem areas for digestate disposal are the presence of metals, plastics and glass.

The experience with compost and the Compost Association promoted quality standards has shown that with UK PAS standards compliance good source separation and fine screening before use, a thoroughly acceptable solid (fibrous) compost can be produced.

Considerable downstream processing of the digestate, and strenuous efforts in marketing, will be required to provide the best possible commercial digestate products.

The AD plant operators will need to obtain assured outlets for the sale of the processed digestate.

Due to the heavy/ dense characteristics of digestate compost transport to sales outlets will tend to be expensive and thus offset any profits.

So this returns us to the original question and the subject of this article. Should we send anaerobic digestate to disposal to landfill, or to recovery?

Digestate Disposal – Conclusion

The suitability of any digestate for fertiliser use and product production for sale off-farm will depend on the feedstock materials used and local planning and waste management circumstances to a very large extent.

A BMW digestate and sewage sludge biogas plant digestate will normally contain contaminants such as heavy metals. These often prevent its use as a fertiliser for food crops, and if landfill capacity is available locally, landfill disposal may be the best option for this material.

High nitrogen and some other organics present may reduce the permissible rate of spreading digestate. And, if chemical accumulation occurs in soils the use of digestate fertilizer will have to be curtailed after a predetermined number of spreading seasons.

Historically in the UK, digestate from some sewage sludge digesters (i.e. wastewater treatment plant, sludge treatment biogas plants) has simply been spread on landholdings that have been permanently classed as unsuitable for food crop use. The reason that they will not be used for food crops in future is that some contaminants in the digestate have accumulated in the soil to concentrations above acceptable levels for food crop production.

Hopefully, nevertheless, as time progresses and:

- food waste source segregation becomes established practice nationally which removes problem contaminants

- better ways are found to make the digestate a better-balanced fertilizer

- coupled with a greater acceptance by potential digestate fertilizer users of the crop benefits of good anaerobic digestion derived soil conditioners,

the result will be a much greater uptake of the AD output of digestate as a product rather than a waste.

Meanwhile, let’s not forget that using Anaerobic Digestion to process the organic fraction of mixed municipal waste has real benefits even if only to render the output sufficiently low in organic content to classify it as no longer BMW.

By such actions, waste managers will be both protecting the environment around our landfills, and also very substantially reducing the tonnages placed in the dwindling stock of landfill void space.

You are my intake. I have a few blogs and frequently run out from to post. I use your articles for my blog, so awesome thanks.

Agradeço-lhe boas notícias do Reino Unido.

I am so grateful for your post. How will it be possible to know the composting has reduced the organic content sufficiently to no longer be BMW? Really looking forward to read more. Cool.