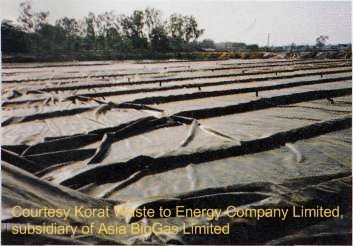

A simple, low capital cost, anaerobic digestion process using the Covered Anaerobic Lagoon Process

A simple, low capital cost, anaerobic digestion process using the Covered Anaerobic Lagoon Process

The process which we have named as the “Covered Anaerobic Lagoon Process” has been around since the development of geomembrane lining systems for low-cost water storage. This method of encapsulating a lagoon to make use of the biogas has been in use since the 1950s when plastic membranes first became available.

It was soon realised that for farmers and other site owners which create manure and also possess abundant land the use of these linings to form lagoons provides the lowest possible cost for large scale water storage in anaerobic digestion conditions. The rate of creation of biogas is low due to the lack of insulation and corresponding low temperatures, nevertheless, the installation cost of this type of biogas plant is also low.

Also, once the lagoon has been formed and lined, the provision of a floating geo-membrane cover to contain all odours is a simple matter. In most systems if allowed to inflate, the “floating cover”, will also provide a simple means of methane storage.

Much older and smaller versions of this process, which predate the advent of geomembranes have been around for several hundred years in China, and to a lesser extent India, where small earthen tanks provide sewage sludge digestion in a form which provides methane for cooking, and water heating.

The main modern-day users of this type of covered anaerobic lagoon process plant have been industries producing high strength industrial wastewaters (eg the food processing industry), and the agricultural industry, to treat their sludges.

In the past some covered anaerobic lagoon process systems were deployed primarily to provide water treatment, with additional aerobic post-treatment prior to discharge.

However, the majority of covered anaerobic lagoon process systems have been installed to provide both a liquid effluent that can be sprayed on their land as a natural fertiliser and for their gas making ability, where the gas produced is usually be used within the facility as an energy source.

Currently lagoons of this type may be constructed more for their methane generation than in the past.

Typically for anaerobic lagoons the detention time might be anywhere in the range 20 to 50 days.

In cold climates the covers normally incorporate additional layers for heat insulation, and as the lagoons are generally not heated they tend to operate in the 15 to 25oC temperature range.

Advantages:

- relatively cheap and low technology

- all plant suitable maintenance by no-specialist fitters etc

- methane produced to provide a very valuable energy source

- effluent has good fertilising quality and composted sludge has very good slow nutrient release characteristics.

Disadvantages:

- need constant attention to the quantity and mix of wastes in order to maintain a good quality biomass for treatment

- inaccessibility of mixers etc for maintenance in many designs

- gas could present an explosion or flash-over risk and site should be risk assessed and an Explosion Protection Document produced for compliance with the ATEX (DSEAR in UK) Directive

- low-temperature operation means long retention periods, so these plants are best suited to warm and hot climates.

The simplicity of these plants means that these can be built as a project using published design guidelines such as in Metcalf and Eddy, “Wastewater Engineering”. However, most would prefer to engage an expert and proprietary installers of these types of plant do exist.

Before installing a covered anaerobic lagoon process system check with your local environmental regulator to ensure that no permits or license is required to build one.

If covers are added to slurry lagoons it is likely that in the UK, the SSAFO Regulations will apply.

Geo-membrane lined lagoons can possibly leak, and we recommend consultation with the local Environment Agency Officer, or a specialist consultant to ensure that you do not construct one of these lagoons in a location where groundwater quality is particularly susceptible to pollution if a leak did occur.

For example it would not be advisable to risk locating a slurry lagoon near a farm water supply well, or abstraction borehole.

— End of November 2014 Article —

What is an Anaerobic Lagoon?

An anaerobic lagoon or manure lagoon is a man-made outdoor earthen basin filled with animal waste that undergoes anaerobic respiration as part of a system designed to manage and treat refuse created by concentrated animal feeding operations (CAFOs). Anaerobic lagoons are created from a manure slurry, which is washed out from underneath the animal pens and then piped into the lagoon. Sometimes the slurry is placed in an intermediate holding tank under or next to the barns before it is deposited in a lagoon. Once in the lagoon, the manure settles into two layers: a solid or sludge layer and a liquid layer.

The manure then undergoes the process of anaerobic respiration, whereby the volatile organic compounds are converted into carbon dioxide and methane. Anaerobic lagoons are usually used to pretreat high strength industrial wastewaters and municipal wastewaters.

Anaerobic lagoons have been shown to harbor and emit substances which can cause adverse environmental and health effects. These substances are emitted through two main pathways: gas emissions and lagoon overflow. Gas emissions are continuous (though the amount may vary based on the season) and are a product of the manure slurry itself. The most prevalent gasses emitted by the lagoon are ammonia, hydrogen sulfide, methane, and carbon dioxide. via en.wikipedia.org

Optimizing an Anaerobic Lagoon with a Cover to Make a Digester for Biogas Energy

It's not difficult or expensive to cover an anaerobic lagoon receiving manure slurry.

With a certain amount of care in the design of the lagoon from the outset a flexible plastic cover can be floated on the surface.

The most successful arrangement reportedly includes two lagoons. These are connected in series to separate the digestion stage (biological treatment for biogas production) and storage.

Storage is an essential element of design as the fertilizer which is produced is only for land application in dry weather and twice a year when conditions are right for crop growth.

By splitting the digestion and storage functions the digestion lagoon can be retained full at all times. A variable volume (variable level) one-cell lagoon designed for both treatment and storage may, of course, be covered for biogas recovery.

Constant Volume Anaerobic Lagoons vs Rise and Fall Types

However, constant-volume lagoons are much easier to cover in this way. A single-cell lagoon cover will need some mechanism to allow lagoon level rise and fall without the biogas collection capability of the cover being comprised.

The first stage (digester) lagoon is anaerobic throughout. Biological treatment of the slurry takes place here, as does methane production. This being the case the storage lagoon is far less odorous.

At the very least the anaerobic lagoon system will normally provide a form of odour reduction and control. However, close to housing in odour sensitive locations the storage lagoon may still need a cover for odour control.

Ideally, diluted manure contaminated yard runoff is piped to the secondary lagoon. The secondary lagoon rises and falls in level as variable volume storage.

When the season and climatic conditions are right, the stored liquid in the second lagoon can be used for irrigation, recycle flushing, or other purposes.

The Importance of Bio-Reactor Temperature for Biogas Yield

Temperature is a key factor in the rate of biogas production in these unheated lagoons. Digestion is more rapid in warm climates, so in tropical regions lagoons, may be smaller, and experience less variation in seasonal gas production.

At cooler temperatures, such as in northern California winter methane production reduces substantially. It is important that the operator of an anaerobic lagoon adjusts downward the feeding of organic matter in Winter, to allow for the lower temperatures.

In cold weather, loading rates are decreased and hydraulic retention time (HRT) is increased.

When considering the financial viability of a new anaerobic lagoon always take care of the calculation of costs covering cold weather when seasonally reduced methane yield is most marked. via rcmdigesters.com

This is a topic that’s close to my heart…

Please feature our anaerobic digestion slurry lagoon cover system.

Agricultural slurry and waste water lagoons create anaerobic conditions where methane and carbon dioxide (biogas) are naturally produced. This is normally released into the atmosphere wasting a valuable fuel resource as well as releasing a potent greenhouse gas.

LagoonQUBE is designed to perform the dual purpose of capturing the biogas on existing slurry lagoons with the added benefit of also collecting rainfall and so reducing storage volume. The collected biogas can then be used for heat and power generation.

LagoonQUBEs are lightweight inflatable modules designed to float on the surface of the existing lagoon and collect and capture the rainfall and biogas produced. Each lagoonQUBE is a hexagonal module measuring 94m2 and having a diameter of 11.6 metres. The hexagonal design means that the lagoonQUBE’s fit together in any number and can cover as much of the lagoon surface as required. There is more about LagoonQUBE here.

Cheers!

Yes. I will. LagoonQUBE looks like a great idea. So simple. Collect the biogas which would otherwise contribute to the greenhouse effect when it bubbles off into the atmosphere. Thanks for letting us know about this system.

I have checked your website and i have found some content about floating covers on this page,

but there is a good page about this at https://floatingcovers.wordpress.com/tag/lagoon-covers/ that can help you to understand how these work.

Readers may want to see the diagrams there.

You encourage these manure ponds. Are you not aware that after hurricanes these things which called hog lagoons, collect the animals’ feces overflow? The result is extremely high levels of dangerous bacteria in our floodwater. Clever. Huh?

I want readers to understand that in windy weather especially these large covers need constant attention or small leaks, small damage can become major. Neglect can bring severe consequences. Any damage needs to be actively identified and repaired. Operating a lagoon cover requires removing the collected biogas from below the cover regularly or continuously. The cover should be visually inspected weekly and more often during high winds for rainwater accumulation, tearing, wear, and proper tensioning of attachment ropes.