“Is my waste suitable for anaerobic digestion?”, is a frequent question we receive in our emails. It comes from those considering installing agricultural AD systems, and businesses that produce food waste especially.

There are two immediate considerations for any answer, the first is to say that more or less any organic material can be anaerobically co-digested if mixed with other materials, including woody feedstocks. Unlikely sounding materials such as egg-shells and feathers can also be fermented. Materials which can, in general, be fermented as sole feedstocks into an AD Plant are provided in the next section below:

There are two immediate considerations for any answer, the first is to say that more or less any organic material can be anaerobically co-digested if mixed with other materials, including woody feedstocks. Unlikely sounding materials such as egg-shells and feathers can also be fermented. Materials which can, in general, be fermented as sole feedstocks into an AD Plant are provided in the next section below:

General Considerations for a AD Plant Feedstock as a Suitable Waste for Digestion

In principle, all organic, non-woody substances can be fermented as the sole feedstock in biogas plants.

However, not all substrates are equally suitable and equally productive in terms of the production of biogas. There are three areas, from manure substrates to food waste where the hygiene rules for substrates differ, and increasingly different and stricter legal regulations must be observed.

All classifications of waste fall within a set of hygiene classifications of which the regulations which apply to food waste are the most important (for the UK requirements Google for “Animal By-products Regulations”). In many nations the following substrates are considered as manure systems and are suitable for anaerobic digestion, although some may require special hygiene licensing for regulatory compliance:

- Disposals of animal husbandry such as manure, manure, manure water, manure separation outputs, etc.

- Disposals of crop production grass, silage, vegetable, grain husks, rice husks, crop residues, etc.

- Organic waste of private, commercial, or industrial origin such as municipal bio and green waste, leafy materials, catering waste, waste fat, whey, glycerin, rumen content, etc.

- Slaughterhouse waste and other hygiene risk substrates. (Fermentable substrates only after prior, or post, hygienization (such as pasteurisation).)

- Furthermore, the substrates grouped under the abbreviation of energy crops (renewable raw materials) such as corn, grass, grain, silage, etc. are suitable for fermentation, but this category is usually frowned upon given that the preferred use is for sale as food.

Other Considerations of Waste Suitability

Nevertheless, there are other important considerations that are explained in the next 2 sections, not related to the material but to do with:

- its seasonality, and

- whether the quantity available would be of a strength to be sufficiently productive in biogas output to provide an adequate economy of scale to make a biogas project feasible. This raises the following questions:

- is the strength of the feedstock low (as characterized by, for example, effluent from an earlier process), and

- even if the strength is high, is the quantity adequate for a viable AD plant project?

Seasonality

When considering whether a waste is suitable for anaerobic digestion an important consideration is the seasonality of supply.

A good example of how seasonal variations in the availability of a feedstock can affect the suitability of an AD feed material is the Dairy industry. The economic viability for a Dairy operation AD Plant, based on manure as the feedstock, will be far better for a farm that houses their herd indoors all year round, when compared with a farm on which the herd is out in the fields for 6 months each year.

This is an important consideration, but even for the time where the stock is outside for much of the year, viability will be better if the manure is already stored for summer spreading. Seasonality may also be improved of silage is stored and used at times when manure may not be available.

That's just one reason for the fact that there is certainly no one easy answer to the equation of “Is my waste suitable for anaerobic digestion?”

However, we duplicate a table below which may help to answer the question of what is the minimum economically viable feedstock quantity, for different feedstocks.

Suitability of Common Agricultural Feedstocks for Anaerobic Digestion According to Rate of Supply

We found one possible approach to answering the question of “do I have enough waste to make it suitable for anaerobic digestion”, which we would like to bring to your attention.

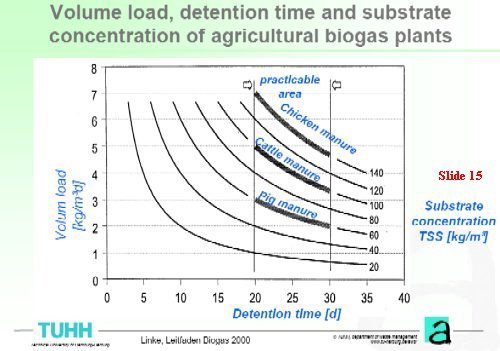

It was available [in 2014] when we wrote this page, as a slide in an excellent free downloadable presentation from a TUHH, Department of Waste Management Workshop in Anaerobic Digestion and Production of Biogas, Prof. Dr.-Ing. R. Stegmann, Dipl.-Ing. Olaf Bade, Chimatra Workshop 2005. (Originally available from Linke, Leitfaden Biogas 2000.)

Our readers must certainly verify the numbers on the graph, nevertheless, we think that the plot is useful to demonstrate the interaction between volume load, detention time, and substrate concentration for biogas plants.

Volume load is the amount of daily supplied substrate per volume of the digester.

First, we have the variability of the calorific yield from the particular biomass feedstock, and from the above paper, it is clear that for a lower calorific yield agricultural waste such as chicken manure the volume load will need to be significantly higher than for a higher calorific yield waste feedstock such as pig manure.

Even so, the assumption is made that the economically viable substrate concentration will be higher for the low calorific feedstocks than for the higher calorific ones. In this example, pig manure is shown as viable down to 60 kg/m3/day, but don’t rely on these numbers, obtain verification yourself.

Detention times within the reactor also need to be within a reasonable range, and the author has assumed 20 to 30 days, for optimum methane production. However, this optimum period varies with each feedstock, as is shown on the slide from the above presentation. (We think that this slide refers to mesophilic fermentation but again you must check this yourself.)

[Sorry, the original paper is no longer available, so the link to this presentation has been deleted. – Webmaster (Sept 2009).]

Conclusion to the Question: “Is My Waste Suitable for Anaerobic Digestion?”

Of course, the economic viability of any project will vary according to many more parameters than those discussed above, but at least the table provided above may provide a basis for a first-pass preliminary assessment of the viability of your feedstock for anaerobic digestion.

If you have a suitable waste which may form the basis for a biogas project, your next step is to look for an anaerobic-digester-for-sale