Efficient biogas utilisation is all about not only generating electricity or biomethane from the biogas but also using the “waste” heat (from the cooling of the engines through direct combustion) in Combined Heat and Power (CHP) units. CHP is seldom discussed; the heat exchangers used have been around for a long while, they don't look very impressive, and the subject holds little interest for many people. Yet, they are so common that virtually all of today's biogas plants use combined heat and power plants.

Main Points to Consider About Efficient Biogas Utilisation

- Biogas CHP units are incredibly efficient, reaching between 80-90% energy efficiency by making use of waste heat that would normally be lost in traditional generation systems.

- These systems are capable of tackling waste management issues while producing renewable electricity and useful thermal energy from organic materials.

- Many agricultural operations, municipal facilities, and food processing plants can achieve energy independence with properly sized biogas CHP installations.

- The production of both electricity and heat allows for multiple revenue streams and a significantly quicker return on investment than single-output energy systems.

- SMG Industries provides top-of-the-line biogas CHP solutions that maximise efficiency while minimising operational complexity for organisations of all sizes.

Biogas combined heat and power systems are one of the most underused yet potent tools in our renewable energy arsenal. These amazing systems turn what was once considered waste into valuable energy, capturing both electricity and heat from a single fuel source. With the world's energy demands increasing and concerns about climate change growing, SMG Industries is helping organizations utilize this technology to create sustainable energy cycles that benefit both business operations and environmental goals.

Unleashing the Power of Biogas CHP Systems

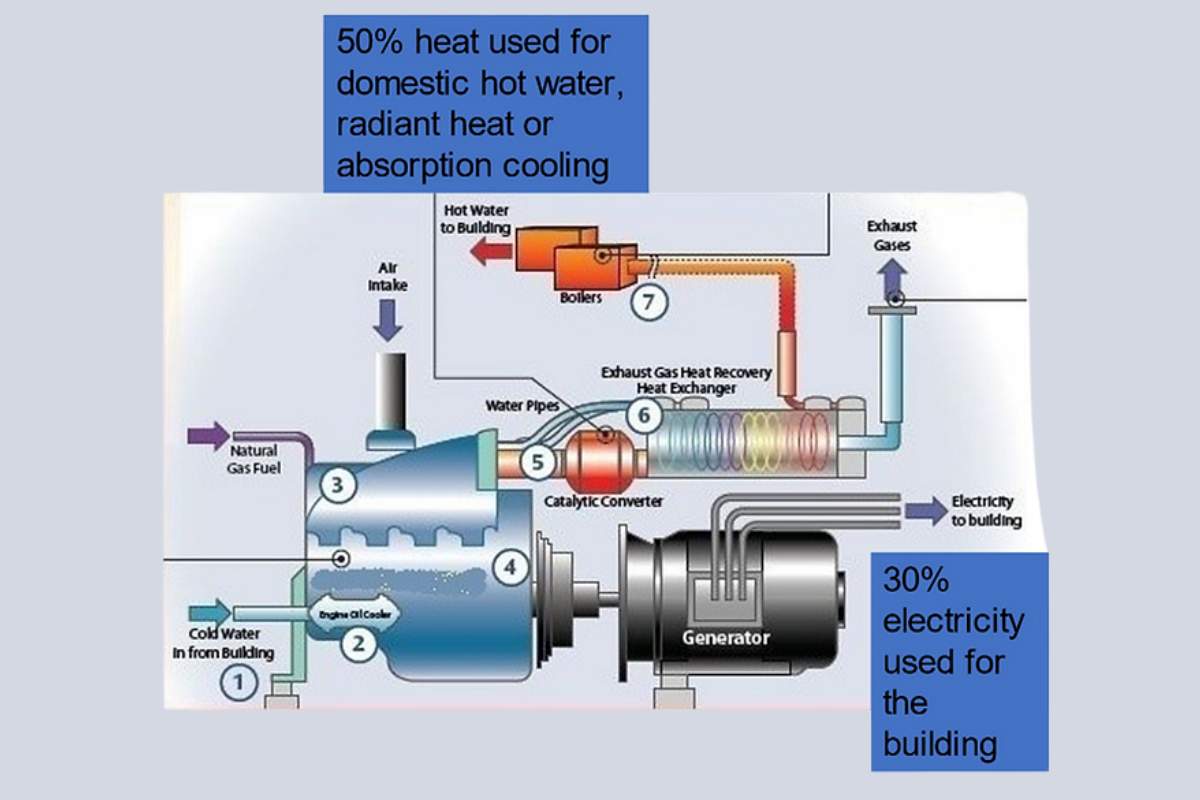

“Cogeneration – Wikipedia” showing how efficient biogas utilisation is achieved from en.wikipedia.org and used with no modifications.

Biogas combined heat and power (CHP) technology represents the perfect marriage of waste management and renewable energy production. Unlike conventional power generation systems that only focus on electricity, biogas CHP systems harness and use both the electrical and thermal energy generated during the combustion process. This dual-purpose approach turns organic waste, from livestock manure to food processing waste, into two valuable sources of energy. The process creates a win-win situation: waste becomes fuel, fuel produces electricity and heat, and these two forms of energy power operations that would otherwise rely on fossil fuels.

Biogas CHP is a game-changer because it is a closed-loop system. The same operations that create organic waste – such as farms, food processing plants, and wastewater treatment facilities – can use that waste to create the energy they need to run. This provides a level of resilience and sustainability that is hard to find in other energy technologies. The principles of the circular economy that are built into biogas CHP point the way to the future of integrated energy systems, where waste is seen as a valuable resource rather than a costly disposal problem.

Why Biogas Combined Heat and Power is So Efficient

Biogas CHP systems are incredibly efficient because they take a waste-to-energy approach to power generation. When electricity is produced in the traditional way, up to 60% of potential energy is wasted as heat that escapes into the atmosphere. Biogas CHP systems, on the other hand, capture this thermal energy and put it to good use, which dramatically increases overall efficiency. This comprehensive use of energy results in a ripple effect of benefits: more energy output per unit of fuel, lower operational costs, and a significantly reduced environmental impact compared to traditional energy systems.

Understanding the Functioning of Biogas Combined Heat and Power Systems

“Biofuels, Biogas, CHP Systems | Alberta …” efficient biogas utilisation from arkltd.net and used with no modifications.

Essentially, a biogas CHP system is a comprehensive energy production facility that combines several technologies. The process starts with the decomposition of organic material and progresses through gas collection, purification, combustion for electricity generation, and heat recovery from the combustion process.

With the help of automation, much of this process is done in modern systems, resulting in dependable power generation that requires little intervention once it has been properly set up. The modularity of many systems allows for scalability, making biogas CHP feasible for both small agricultural operations and large municipal facilities.

Understanding Biogas Production

The production of biogas is a natural process that involves the decomposition of organic materials in an environment that lacks oxygen, which is known as anaerobic digestion. Bacteria, which are housed in specially designed digesters, consume organic matter and produce biogas, a byproduct that is primarily composed of methane (50-70%) and carbon dioxide (30-50%). This process consists of four main stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis.

Each stage involves different bacterial communities that work together to transform complex organic compounds into simple molecules and ultimately into biogas. The controlled environment of an anaerobic digester optimizes conditions for these bacteria, which speeds up the decomposition process that would naturally occur, but at a much slower pace, in landfills or compost piles.

Transforming Biogas into Electricity

Once harvested, biogas becomes the fuel for specialized engines or turbines that are designed to operate with methane-rich gas. These engines are connected to generators that convert mechanical energy into electrical power through electromagnetic induction.

Modern biogas engines are remarkably efficient at converting the chemical energy in biogas to mechanical energy, with electrical conversion efficiencies typically ranging from 35-40%. The engines are specifically designed to handle the variable composition of biogas, including trace contaminants that would damage conventional natural gas engines. Advanced control systems continuously monitor and adjust combustion parameters to maintain optimal performance despite variations in biogas quality.

Waste Heat Capture and Use

CHP systems are ingenious in their ability to capture thermal energy that would otherwise go to waste. Heat exchangers draw thermal energy from various sources: engine cooling systems, exhaust gases, and oil cooling circuits. This makes the efficiency of biogas utilisation so much better.

This reclaimed heat is in the form of hot water or steam at temperatures ranging from 80°C to 500°C, making it useful for a variety of applications, including space heating, process heat, absorption cooling, and even additional electricity generation through steam turbines.

Advanced heat recovery systems can capture up to 50% of the energy input as useful thermal energy, significantly improving the overall system efficiency.

Reaching 80-90% Energy Efficiency

Biogas CHP systems consistently achieve 80-90% combined electrical and thermal efficiency, far outperforming traditional power generation. This impressive efficiency is achieved by harnessing energy that would otherwise be wasted as heat in traditional electricity-only generation.

When these systems are correctly integrated into facilities with both electrical and thermal energy needs, they provide exceptional value by maximising the utility of each unit of biogas produced.

This efficiency translates directly into operational savings and a faster return on investment, making biogas CHP increasingly appealing as energy costs rise worldwide.

The Top 6 Advantages of Biogas CHP Systems

“Powering Ahead – Biogas CHP” – Optimised Biogas Utilisation from www.linkedin.com and used with no modifications.

Biogas CHP technology provides an impressive array of economic, environmental, and operational benefits that are hard to find in other energy systems. These systems turn what was once thought of as waste into valuable energy, all while tackling multiple challenges that modern organisations face.

From reducing energy costs to improving carbon footprints, the benefits make a strong argument for implementing these systems across a variety of sectors. For example, the co-digestion of food waste and sewage sludge is an innovative approach that enhances biogas production and efficiency.

1. Huge Savings in Energy Expenses

Companies that use biogas CHP systems generally see their energy costs drop by 40-60% compared to traditional grid electricity and individual heating systems. These savings are due to the high efficiency of cogeneration, the elimination of transmission losses through on-site production, and the use of waste materials as fuel rather than purchased energy. For operations with a lot of organic waste, this is a win-win situation: waste disposal costs are eliminated and valuable energy is generated. The stability of self-generated energy also provides protection against the unpredictable prices of the energy market, resulting in predictable operational costs that make financial planning easier.

2. Significant Reduction of Carbon Footprint

Biogas CHP systems are capable of dramatically reducing greenhouse gas emissions through several methods. Firstly, they capture methane that would otherwise escape into the atmosphere – a greenhouse gas that is 25 times more potent than CO₂. Secondly, they reduce the consumption of fossil fuels for electricity and heating needs. Thirdly, they reduce emissions related to waste transportation and processing. For organizations that aim to be sustainable, these systems offer quantifiable carbon reductions that can be included in environmental reports and carbon accounting. Many operations are able to reduce their carbon footprint by 60-80% for their energy consumption when they implement comprehensive biogas CHP solutions.

3. Solution for Waste Management

Biogas CHP systems elegantly solve waste management challenges by converting organic waste into energy. They can process manure, crop residues, and spoiled feed in agricultural operations. Food processors can use production waste, expired products, and processing byproducts. Municipalities can process food waste, yard trimmings, and biosolids from wastewater treatment. This integrated approach reduces landfill use, eliminates disposal costs, and turns problematic waste streams into valuable resources. The resulting digestate also serves as a nutrient-rich fertilizer, adding more value to what was once considered waste.

4. Energy Autonomy and Stability

Producing energy on-site significantly increases resilience against power cuts, energy price changes, and supply interruptions. Organizations that have biogas CHP systems can keep their most important operations running during power cuts, reducing their vulnerability to failures in the external energy infrastructure. This autonomy is especially beneficial for agricultural operations, food processing facilities, and critical infrastructure where it is essential to keep operations running. Many systems can operate in island mode, completely disconnected from the grid, providing energy stability in remote locations or during emergencies.

5. Adaptable Size Choices

Biogas CHP technology can be adjusted to fit everything from tiny farm tasks to large industrial projects. Modular systems can start small and grow as demand increases or as more raw materials become available. This adaptability makes the technology available to projects of all sizes and allows for gradual implementation to spread out the initial costs over time. Modern systems also adjust to changes in the availability of raw materials, maintaining efficiency across a range of loads and operating conditions.

6. Diverse Income Streams

Aside from cost savings, biogas CHP systems can create diverse income streams for operators. These can include selling surplus electricity back to the grid, selling renewable energy credits or carbon offsets, supplying heating or cooling to nearby facilities, and selling nutrient-rich digestate as fertilizer. In many areas, government incentives for renewable energy production and waste diversion create extra financial benefits. These diverse income opportunities improve the financial case for biogas CHP implementation and speed up return on investment.

Practical Uses of Biogas CHP Systems

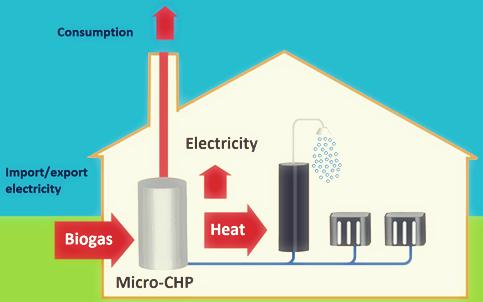

“Micro Combined Heat and Power Market …” from www.openpr.com and used with no modifications.

Biogas CHP systems are revolutionizing a variety of industries with their flexible deployment options. The technology's ability to adapt to different waste streams and its scalability make it ideal for a range of uses, from small country farms to large industrial facilities. Real-life examples show how these systems create sustainable energy cycles that are good for the environment and the bottom line. For instance, the co-digestion of food waste and sewage sludge is one method that enhances biogas production efficiency.

Choosing the right system configuration that fits the specific operational needs and available feedstock is the secret to a successful implementation. Organizations that have a clear understanding of their waste streams and energy requirements can create highly optimized systems that can maximize both economic and environmental benefits.

From Waste to Power: Biogas CHP in Agriculture

Given the steady production of organic waste materials, farms are the perfect settings for the implementation of biogas CHP. Dairy farms, for instance, can convert the manure from hundreds or thousands of cows into electricity. This can then power milking parlors, refrigeration systems, and other operations on the farm. At the same time, the thermal energy can provide hot water for cleaning equipment and heating livestock buildings. Advanced biogas systems in agriculture can process mixed feedstocks. This includes crop residues, spoiled silage, and even food processing waste from nearby facilities.

A 500-cow dairy farm in Wisconsin serves as a prime example. This farm installed a 140 kW biogas CHP system and now produces enough electricity to power all farm operations and 70 nearby homes. Additionally, it creates hot water that saves $45,000 in annual propane costs. The system's digestate is a superior fertilizer that has increased crop yields by 15% and reduced odor complaints from neighbors by 90%. This illustrates the many benefits beyond energy production.

Efficient Biogas Utilisation with CHP at City Sewage Treatment Plants

Sewage treatment plants are one of the best places to implement combined heat and power (CHP) units because they naturally produce biogas during the treatment process. Many modern plants are now capturing this biogas from their anaerobic digesters and using it to power their operations. This creates a self-sustaining plant that doesn't need much energy from outside sources. The heat energy from the CHP units is used to keep the digesters at the right temperature, heat the buildings at the plant, and speed up the process of drying sludge.

One of the most successful wastewater biogas CHP systems in North America is run by the East Bay Municipal Utility District in Oakland, California. They have increased biogas production by 190% by accepting food waste in addition to typical wastewater. This generates 11 MW of electricity, which is enough to power the entire treatment facility and around 13,000 homes. This shows that municipal infrastructure can become part of the renewable energy solution, as this approach has turned the facility from an energy consumer to a net energy producer.

Food and Beverage Manufacturers and Organic Waste Generators

Food and drink producers create significant organic waste streams, which are ideal for biogas production. Breweries use spent grain and yeast, dairy processors use whey and out-of-date products, and vegetable processors turn trim waste and rejected produce into useful energy. These processes benefit from both waste reduction and energy production, creating circular systems that simultaneously improve sustainability metrics and operational expenses.

A Wisconsin-based cheese producer has put a biogas CHP system into operation that treats 500,000 gallons of high-strength wastewater each day. The system generates 1.2 MW of electricity and provides all of the hot water the facility needs, saving $2.1 million in energy costs each year and eliminating wastewater surcharges. The closed-loop system has become a key part of the company's sustainability marketing, helping to secure lucrative contracts with environmentally aware retail partners.

Finding the Best Biogas CHP System for You

When it comes to choosing the best biogas CHP system, there's a lot to consider. You have to think about the feedstock you have available, your energy needs, the amount of space you have, and your budget. The most successful projects start with a detailed feasibility study. This study looks at all these factors and uses them to create models of different systems. This careful approach helps avoid expensive mistakes like choosing a system that's too big or too small. It also makes sure the system you choose is a good fit for your operation.

Small-Scale vs. Large-Scale Systems for Efficient Biogas Utilisation

Biogas CHP systems come in a variety of sizes, from small-scale units that produce 10 kW for tiny farms to large-scale facilities that generate several megawatts. Small-scale systems are usually less complicated, with lower initial costs and easier permitting requirements, making them more accessible to smaller businesses. These systems often use standardized, modular components that make installation and maintenance easier. Large-scale systems provide economies of scale that improve efficiency and lower per-kilowatt costs, but they require more advanced monitoring and control systems, as well as more operator expertise.

The choice between scales is mostly determined by the availability of feedstock and energy requirements. Companies should leave room for growth, as many successful implementations eventually exceed initial estimates as additional waste streams are identified and incorporated. Modern systems offer incredible turndown ratios, allowing for efficient operation under varying load conditions to accommodate seasonal variations in both waste production and energy requirements.

Crucial Technical Aspects to Keep in Mind for Efficient Biogas Utilisation

When choosing a biogas CHP system, there are a few important technical factors to consider. The electrical efficiency of the system, which usually falls between 35% and 45%, is a measure of how well the system can convert biogas into electricity. The thermal efficiency, which is typically between 40% and 50%, shows how well the system can recover heat. The total efficiency of the system is the combination of these two figures and should be over 80% for modern systems. The type of engine used can have a big impact on how much maintenance is required and how well the system can handle impurities in the biogas. Engines that are specifically designed for biogas generally perform better and are more reliable in the long run than engines that have been converted from natural gas.

Other things to consider are the capacity for automation, the option to monitor remotely, the requirements for grid interconnection, and the storage capacity for biogas. This last point is especially important for operations where waste production is variable or where energy demands fluctuate. It allows for the system to operate consistently despite these variations. More and more, modern systems are including complex control systems that optimise performance based on the current conditions. Some even include predictive algorithms that can anticipate changes in the production of biogas or in energy demands.

Ensuring System Size Complements Available Feedstock

Thorough feedstock assessment is crucial to determining the correct system size. Companies need to evaluate both the amount and quality of accessible organic materials, taking into account seasonal fluctuations and possible future operational changes. The amount of biogas produced can differ greatly depending on the type of feedstock, with high-fat food waste generating up to five times more biogas per ton than cattle manure. Professional lab testing of potential feedstock can provide essential information on methane potential, nutrient content, and potential contaminants.

Systems that are correctly sized usually make use of 80-90% of the available feedstock capacity. This leaves some room for fluctuations and future expansion. If a system is undersized, it leaves potential energy production unused. On the other hand, if a system is oversized, it operates inefficiently and increases the payback periods. Many successful implementations start with modular designs. This makes it easier to expand in the future as operations grow or additional waste streams become available.

AI hasn't got a clue how to show pipework! Just don't ask AI to do any plumbing design for you!

Putting It Together: Getting Your Biogas CHP System Up and Running for Efficient Biogas Utilisation

From the drawing board to the power grid, every step requires meticulous planning, flawless execution, and continuous fine-tuning. Successful biogas CHP projects follow a well-thought-out process that addresses potential issues and includes plans for dealing with them. Even the most well-engineered systems need regular maintenance to keep them running at their best, so knowing how to operate them is key to their long-term success. For those interested in smaller-scale projects, learning how to build a mini biogas plant can be a practical starting point.

The Importance of Biogas Pre-Treatment

Raw biogas has impurities that can be harmful to CHP equipment if not handled properly. Hydrogen sulfide (H₂S) leads to corrosion in engines and heat exchangers, siloxanes create abrasive deposits on engine components, and moisture lowers combustion efficiency and speeds up wear and tear.

To ensure the quality of the gas meets the specifications of the engine manufacturer, modern systems use multi-stage cleaning processes. These processes may include removing condensate, filtering with activated carbon, and sometimes desulphurising biologically.

Biogas engines that have been specifically designed generally can handle higher levels of impurities than engines that have been converted from natural gas, which could potentially reduce the need for pre-treatment and the associated costs.

Continuous monitoring of gas quality ensures that treatment systems are working correctly and helps to prevent costly engine components from failing prematurely.

Linking to the Grid and Heat Distribution Systems for Efficient Biogas Utilisation Via CHP

Requirements for grid interconnection can differ greatly between utilities and regions, affecting both the technical aspects and the economic feasibility of a project. Most installations necessitate specific interconnection equipment such as synchronisation controls, protective relays, and systems for monitoring power quality.

Larger systems may necessitate upgrades to the utility infrastructure, which the operator must pay for, and this factor must be factored into economic evaluations. Many jurisdictions offer net metering programs that enable operators to balance consumption with production, effectively using the grid as a free energy storage system.

Heat distribution infrastructure is a crucial but frequently ignored aspect of successful CHP deployments. Insulated pipe systems, heat exchangers, thermal storage tanks, and control systems are all used to ensure that thermal energy is delivered to its intended applications efficiently.

The economic viability of heat utilisation (efficient biogas utilisation via CHP) is largely dependent on distance, with applications more than 500 meters from the CHP unit often becoming uneconomical due to heat losses and infrastructure costs. The most successful deployments place heat-consuming processes near CHP units, or vice versa, to maximise thermal utilisation.

Best Practices for Maintenance and Monitoring

Regular preventive maintenance can prolong the life of equipment and ensure it operates at maximum efficiency. The maintenance schedule for engines is based on the number of hours they have been operating, similar to other internal combustion engines. Minor services are typically needed every 1,500-2,000 hours of operation, and major overhauls are required every 30,000-60,000 hours, depending on the type of engine and the quality of the biogas. Digesters need to be cleaned periodically to remove sediment that has built up, and the media in gas cleaning systems need to be replaced according to the manufacturer's instructions. For those interested in setting up smaller systems, learning how to build a mini biogas plant can be a valuable resource.

High-tech monitoring systems deliver performance data in real time and early alerts for possible problems. Contemporary installations use sensors to measure biogas production, composition, engine performance parameters, and both electrical and thermal output. Remote monitoring capabilities mean expert oversight is possible without needing to be on-site all the time, which cuts operational costs while keeping system performance high. Many system providers offer comprehensive maintenance contracts that guarantee availability rates of over 95%, which moves technical risk from the operator to the equipment provider.

Profitability Assessment: The Payback of Biogas CHP Systems

Several factors determine the economic feasibility of biogas CHP systems, including initial outlays, running costs, the worth of the energy produced, any available subsidies, and the savings made from waste disposal. An in-depth profitability assessment takes all these factors into account over the lifetime of the system, which is usually 15-20 years for the CHP unit and 20-30 years for the anaerobic digester. This long-term view can uncover value that might be missed in simple payback calculations.

Running Costs and Energy Savings

The running costs of a biogas CHP system are usually between $0.02 and $0.05 per kWh generated. This includes all maintenance, labor, and consumables. When compared to the retail electricity prices of $0.10 to $0.30 per kWh in most areas, this can create an immediate positive cash flow. When the savings from using thermal energy and waste disposal are taken into account, many systems can achieve running cost advantages of over $0.15 per kWh equivalent. For those interested in exploring smaller setups, a mini biogas plant could be a viable option, potentially leading to a quick return on investment.

Depending on the size and complexity of the system, the amount of work required will differ. Small farm-based systems usually need 1-2 hours of daily attention from current staff, whereas large industrial installations may require dedicated operators. While automation reduces the amount of work required, it increases initial capital costs, creating trade-offs that must be evaluated based on local labor rates and available expertise. Maintenance costs are predictable based on operating hours, allowing for accurate long-term financial forecasting. For more insights on cost management, consider exploring the hidden costs of neglecting airflow systems in biogas plants.

The most profitable implementations make the most of both electrical and thermal energy. Electricity has a more apparent value and is easier to distribute, but thermal energy often accounts for 50-60% of the system's energy output. Operations that can use this heat for existing processes—whether for heating spaces, drying products, or heating process water—perform much better financially than those that focus only on generating electricity. For more information on this topic, you can explore using biogas for combined heat and power.

Example of Yearly Running Expenses for a 500kW Biogas CHP System

Category of Expenditure Cost per Year Cost per kWh Maintenance of Engine $109,500 $0.025 Maintenance of Digester $32,850 $0.0075 Workforce $43,800 $0.01 Consumable Items $21,900 $0.005 Total Operating Expense $208,050 $0.0475 Value of Energy (electric) $525,600 $0.12 Value of Energy (heat) $219,000 $0.05 Savings from Waste Disposal $131,400 $0.03 Total Advantages $876,000 $0.20 Net Benefit per Year $667,950 $0.1525 Calculated on 4,380,000 kWh yearly output, 90% uptime, and average energy costs in the U.S. For more insights into biogas systems, you can explore mini biogas plants and their applications.

Renewable Energy Credits and Available Incentives

Biogas CHP systems are influenced by government incentives, which are significant in terms of financial performance in most regions. These incentives come in several forms, including production tax credits, investment tax credits, grant programs, accelerated depreciation, and low-interest financing. The U.S. Inflation Reduction Act of 2022 enhanced these incentives considerably, providing qualifying biogas systems with up to 50% investment tax credits. Similar programs are available in Europe, Canada, and increasingly in developing economies that recognize the numerous benefits of biogas technology.

Biogas CHP operators can benefit from additional income from Renewable Energy Credits (RECs) and carbon offset markets. These markets place a price on the environmental advantages of renewable energy, and biogas systems often fetch higher prices because of their methane capture component. Depending on the jurisdiction, the value of the credits can range from about $0.01 per kWh in voluntary markets to more than $0.15 per kWh in areas with robust renewable portfolio standards or carbon pricing mechanisms.

Many farming practices also take advantage of nutrient management credits or water quality trading programs that value the improved management of manure and farming residues. These programs acknowledge the water quality benefits of correct waste management and can offer substantial additional income, especially in environmentally sensitive watersheds or regions with strict nutrient management regulations.

Common Return on Investment Times

Return on investment times for biogas CHP systems generally fall between 3 and 8 years, depending on the size of the system, the type of feedstock available, the cost of energy, and any incentives that may apply. Larger systems usually see a quicker return on investment due to economies of scale in both the cost of equipment and operational efficiency. Operations that use high-energy-value feedstock, such as waste from food processing, often see returns at the lower end of this range, while agricultural systems that primarily use manure may take longer to recoup the initial investment.

Most well-designed systems achieve internal rates of return between 15% and 25% when assessed over a 20-year lifecycle. This is on par with or better than many traditional investments. The combination of energy production, waste management savings, and various incentive programs results in this impressive performance. These returns often exhibit less volatility than many alternative investments, as they are relatively shielded from energy market fluctuations and broader economic cycles.

Addressing the Difficulties of Biogas CHP Implementation

Even with their impressive advantages, biogas CHP systems come with their own set of problems that must be tackled for a successful implementation. Being aware of these problems beforehand allows organizations to come up with suitable countermeasures and set achievable goals. Most hurdles can be overcome with the right planning, suitable technology choice, and operational know-how.

The most successful implementations are those that take a careful, methodical approach to the design and operation of the system. They incorporate the lessons learned from the thousands of biogas CHP systems that are operating worldwide. This approach, which is based on knowledge, helps to minimize the technical and financial risks and ensures that the system delivers the expected performance throughout its operational life.

Managing Variability in Feedstock

Biogas systems face operational challenges due to variations in the quantity and quality of feedstock. These fluctuations may be due to seasonal agricultural activities, changes in food processing production, or inconsistent waste collection systems. Modern systems manage this variability using a variety of methods. These include multiple feedstock capabilities, suitably sized storage systems, and advanced feeding equipment that can blend materials to ensure consistent digester loading. The most advanced systems incorporate real-time monitoring of digester biology. This allows operators to adjust feeding strategies based on the actual performance of the digester, rather than fixed schedules.

Dealing with Biogas Impurities

Biogas impurities such as hydrogen sulfide, siloxanes, and moisture can harm engines and lower the efficiency of the system if not properly managed. To effectively deal with these contaminants, suitable gas cleaning systems should be matched with the characteristics of the feedstock and the engine requirements. Contemporary installations include multi-stage cleaning processes with redundant components to ensure non-stop operation. Advanced monitoring systems offer an early warning of a breakthrough or component failure, thereby safeguarding valuable engine assets while keeping the system available. When selecting equipment, cleaning technologies with a proven track record in similar applications should be prioritized over the lowest initial cost, as insufficient gas treatment can quickly lead to costly engine damage. For a deeper understanding of managing biogas systems, explore the hidden costs of neglecting airflow systems in biogas plant workplaces.

Maximizing System Efficiency

Continuous monitoring and regular fine-tuning are essential for keeping a system running at its best. Advanced biogas CHP systems are equipped with numerous sensors that measure various aspects of the process, from the type of feedstock being used to the composition of the engine exhaust. This data is used to maximize system efficiency, with both automated systems and manual operator adjustments playing a role. Regular performance evaluations can identify areas where efficiency is being lost and maintenance is required, allowing these issues to be addressed before they have a significant effect on operations.

Training the operators is a crucial but frequently neglected part of system optimization. Even the most automated systems need informed oversight to interpret data, identify emerging problems, and implement appropriate interventions. Successful operations usually combine automated systems with well-trained personnel who understand both the biological and mechanical aspects of biogas CHP technology. Ongoing training programs keep operators up to date with technological developments and best practices, ensuring the system performs at its best throughout its operational life.

Why It's Time to Invest in the Future of Biogas CHP

Biogas CHP is at a turning point, with several trends converging to create unique opportunities. Regulatory frameworks are increasingly acknowledging and incentivising the environmental benefits of these systems through carbon pricing, renewable energy mandates, and waste diversion requirements.

Technological advances are continually improving performance and lowering costs, with innovations in digester design, gas cleaning, and engine efficiency improving the already strong economics. Perhaps most importantly, the growing commitment of companies to sustainability and carbon reduction creates internal drivers for implementation beyond purely financial considerations.

Today, companies that utilise biogas CHP systems are setting themselves up for success in the changing energy market. They're not only ensuring long-term energy price stability, but they're also tackling waste management issues and lessening their environmental impact.

Early adopters are gaining critical operational experience that will give them a leg up as these systems become the norm rather than the exception. With SMG Industries at the forefront of innovative biogas CHP solutions, companies can rely on tried-and-true technology that comes with full support and expertise.

Common Questions

Here are some answers to the most frequent questions about biogas CHP technology. These insights help address the main concerns for organisations considering implementation and provide useful information for those looking to better understand the technology's capabilities and limitations.

What kinds of organic waste can create biogas for CHP systems?

Almost any organic material can generate biogas through anaerobic digestion, although methane yields can differ greatly between feedstocks. High-performing materials encompass food waste (particularly fats and oils), byproducts of food processing, waste from breweries and distilleries, and specific energy crops.

Animal manures offer stable digester performance but relatively lower gas yields. Many industrial wastewaters also contain significant organic content that is suitable for biogas production.

Modern systems increasingly use mixed feedstocks, combining high-energy materials with more abundant base materials to optimize both gas production and digester stability.

What is the lifespan of a biogas CHP system before it needs to be replaced?

Biogas CHP systems, when properly maintained, have a surprisingly long lifespan. Anaerobic digesters, for example, can function for 20-30 years before they need significant refurbishment. CHP engines, on the other hand, typically run for 60,000-80,000 hours (or roughly 7-9 years of continuous use) before they need major overhauls, which can extend their useful life.

Electronic components and control systems may need to be updated after 10-15 years due to technological advancements. With proper maintenance and occasional component replacement, many biogas CHP systems can operate efficiently for more than 20 years, providing an excellent return on the initial investment.

Is it possible for biogas CHP systems to operate entirely off-grid?

Indeed, biogas CHP systems can operate completely independently of the electrical grid when they are designed appropriately for this function. Operating off-grid necessitates the inclusion of additional components such as sturdy biogas storage, load management systems, and frequently battery storage to manage variations in both production and demand.

How do biogas and natural gas CHP systems differ?

Both biogas and natural gas CHP systems use internal combustion engines to produce electricity and heat, but there are some key differences. Biogas usually contains 50-70% methane, while natural gas contains more than 95%, which means biogas has a lower energy density and different combustion properties.

Engines made specifically for biogas have adjusted compression ratios, ignition timing, and fuel delivery systems to account for these differences. Biogas systems also need stronger gas cleaning equipment to deal with contaminants not usually found in processed natural gas, especially hydrogen sulfide and siloxanes that can harm engine parts.

When it comes to environmental and regulatory aspects, the differences become even more pronounced. In most jurisdictions, Biogas CHP is considered a renewable energy source, making it eligible for a variety of incentives and favourable regulatory treatment that natural gas systems do not qualify for.

The analysis of the carbon footprint also differs significantly, with biogas being considered carbon-neutral or even carbon-negative due to its waste diversion component, while natural gas is still a fossil fuel with associated greenhouse gas impact. These differences are increasingly influencing both economic calculations and corporate decision-making as organizations strive to achieve sustainability goals and prepare for potential carbon pricing mechanisms. For more insights on biogas, explore the benefits of mini biogas plants.

How do seasonal changes affect biogas production and CHP system efficiency?

Seasonal variations impact biogas systems through multiple mechanisms that require consideration in system design and operation. In agricultural settings, feedstock availability often fluctuates seasonally with harvesting schedules and animal housing practices.

Ambient temperature changes affect digester heating requirements, particularly in colder climates where maintaining optimal mesophilic temperatures (95-105°F) requires significant thermal input during winter months. Heating and cooling demands for the facility also vary seasonally, affecting biogas utilisation patterns for the thermal energy produced.

Good systems have features to deal with these seasonal challenges. Digesters that are insulated and partially buried reduce heat loss during cold periods. Thermal storage systems store excess heat during low-demand periods for later use. Feedstock storage facilities allow operators to manage seasonal availability fluctuations.

Some operations also adjust their CHP operating schedules seasonally, maximising electricity production during high-value periods and thermal production during high-demand seasons. These strategies ensure consistent performance and economic returns despite changing external conditions.

Featured Image Attribution: Via Flickr, Lethbridge Biogas Facility, Tonyglen14 https://www.flickr.com/photos/powerline64/33950214352/

Licence: CC BY 2.0