Anaerobic digestion tanks (often known as biogas tanks, or digester tanks) are large, usually circular in plan, and very distinctively topped with their flexible gas storage plastic membrane covers, that are often cone shaped and supported at the centre with a single pole.

These innovative vessels not only treat waste but also generate biogas—a valuable resource.

They are manufactured and installed by a rapidly expanding group of specialist contractors. Tank bases are usually designed and constructed by the EPC/ main infrastructure contractor, usually a civil engineering contractor. Once the base has been completed and the concrete has set and cured, the anaerobic digestion tank specialist will erect the tank walls and cover, and test the tank for water-tightness. Finally it is handed back to the main contractor for installation of all mechanical and electrical equipment (including hot water heating tubes, mixers etc).

Here’s what you can learn about these vital components of modern sustainability.

What You Will Learn

- Anaerobic digestion tanks (digesters) play a vital role in converting organic waste into biogas, contributing to renewable energy efforts.

- Understanding the core components of these tanks—like the digester chamber and gas collection system—can enhance their efficiency and functionality.

- The choice of materials—steel, concrete, and innovative composites—affects the tank's longevity, maintenance needs, and overall performance.

- Emerging trends such as modular designs and variants on the original single fully mixed tank CSBR systems are shaping the future of anaerobic digestion technology.

- Selecting the right anaerobic digestion tank involves considering size, material type, and location to maximize output and compliance with regulations.

- Engaging with the anaerobic digestion community through industry associations, online forums, and workshops can provide valuable resources and knowledge sharing.

- Staying updated on advances in anaerobic digestion technology and practices is essential for ongoing success in the field.

Understanding Anaerobic Digestion Tanks: An Overview

Defining Anaerobic Digestion Tanks and Their Purpose

Anaerobic digestion tanks are specialized vessels designed to break down organic material without oxygen. They serve a crucial role in managing waste while producing valuable biogas. This process not only helps in waste treatment but also contributes to renewable energy production.

Anaerobic digestion tanks are specialized vessels designed to break down organic material without oxygen. They serve a crucial role in managing waste while producing valuable biogas. This process not only helps in waste treatment but also contributes to renewable energy production.

In these tanks, microorganisms consume organic matter, resulting in methane and other useful gases. The biogas generated can be used for electricity, heating, or even as vehicle fuel.

By understanding their purpose, we can appreciate their significance in sustainable practices.

Key Components and Structure of Anaerobic Digestion Tanks

Anaerobic digestion tanks consist of several key components that ensure effective operation. These include:

- Feedstock Input: Where organic materials are introduced.

- Digeser Chamber: The main area where digestion takes place.

- Gas Collection System: Captures the produced biogas.

- Mixing Mechanism: Ensures even distribution of materials.

- Heating System: Maintains optimal temperature for digestion.

The structure of these tanks often varies, with shapes ranging from cylindrical to rectangular and even balloon shape for some plug flow digesters. Each design caters to specific needs, enhancing efficiency and functionality. Understanding these components helps in optimizing tank performance for various applications.

The tanks described are used in wet anaerobic digestion processes, so called “dry anaerobic digestion” is not done in tanks.

The Construction and Materials Used in Anaerobic Digestion Tanks

Materials for Large-Scale Anaerobic Digestion Tanks

When it comes to large-scale anaerobic digestion tanks, the construction materials play a significant role in their longevity and efficiency. Common materials used include:

- Steel: Known for its strength and flexibility.

- Concrete: Offers durability and resistance to harsh conditions.

- Composite Materials: Combine the benefits of different materials.

- Stainless Steel: Adopted recently by some designers for its long-lasting corrosion free properties.

Steel Tanks: Benefits and Drawbacks

Steel tanks are popular for their robust nature and ability to withstand pressure. They can be easily fabricated and transported, making installation straightforward. However, they might be prone to corrosion, requiring regular maintenance.

Sectional Steel Tanks

The most common anaerobic digestion tanks are manufactured from numerous curved steel panels. Each panel is first zinc or glass coated. An epoxy layer is usually also be applied over the initial protective layer, for further corrosion protection.

The steel tank wall arrives on-site fully prepared, in sections, and the whole tank and is quickly erected crane llfting and by bolting together each panel on-site.

Gaskets are provided between the steel surfaces to provide a watertight seal. The base of the wall is then usually cast into a concrete ring beam for a water-tight seal between the tank walls and the reinforced concrete base slab.

When constructed in mild steel the anaerobic digestion tank itself is not normally visible from outside the tank. What is visible is an external (protective and waterproof) outer cladding, that includes a heat insulation layer. The structural wall of the tank is usually not visible.

Stainless Steel Sectional Bolted Anaerobic Digestion Tanks

Due to the fact that the surface coatings of steel tanks once penetrated by becoming chipped or worn, can rapidly corrode and holes may develop at these points. some clients seek more a more robust anaerobic digestion tank solution.

The corrosive nature of biogas can seriously shorten the life of mild steel sectional tanks, and concrete tanks are slow to build and expensive if reinforced.

Stainless steel can be the solution.

Stainless steel may be a more expensive material than any of the alternatives, but by not needing a protective coating it avoids the corrosion concerns of mild steel sectional bolted tanks, and yet retains all the benefits of fast erection. The German biogas plant company, Weltec is known for its use of stainless steel tanks.

Concrete Tanks: Longevity and Maintenance Considerations

Concrete tanks are often favored for their durability, lasting many years with minimal upkeep. They are excellent at insulating against temperature changes, promoting efficient digestion.

On the flip side, repairing reinforced concrete, if needed, can be more complex and expensive than other materials.

Concrete tank construction

Cast in-place reinforced concrete tanks require a lot of formwork to build them, as most tanks are cast in one long pouring/ casting session. They have a higher initial construction cost than steel alternatives, but once completed do not normally corrode significantly and may last 30 years or more with little or no maintenance.

Construction times for cast in-place concrete tanks affect the critical path more than other tank types as the concrete must be allowed to cure before the tanks can be filled. Curing may take 30 days.

Pre-cast pre-stressed and post stressed pre-cast concrete anaerobic digestion tanks are normally sectional in construction and erected from a series of full height “planks” which are carefully jointed and sealed together and also sealed down on to the concrete base slab.

Stressing cables are wound around the perimeter and when tightened take the full circumferential load. The stressing design is proprietary and varies between the suppliers.

Sectional concrete tanks have a poor reputation for leaking as they depend upon rubber or mastic seals between each joint. Sectional steel tanks also depend on synthetic rubber seals between each steel plate, and yet they last well, are securely held between overlapping steel faces have a good reputation.

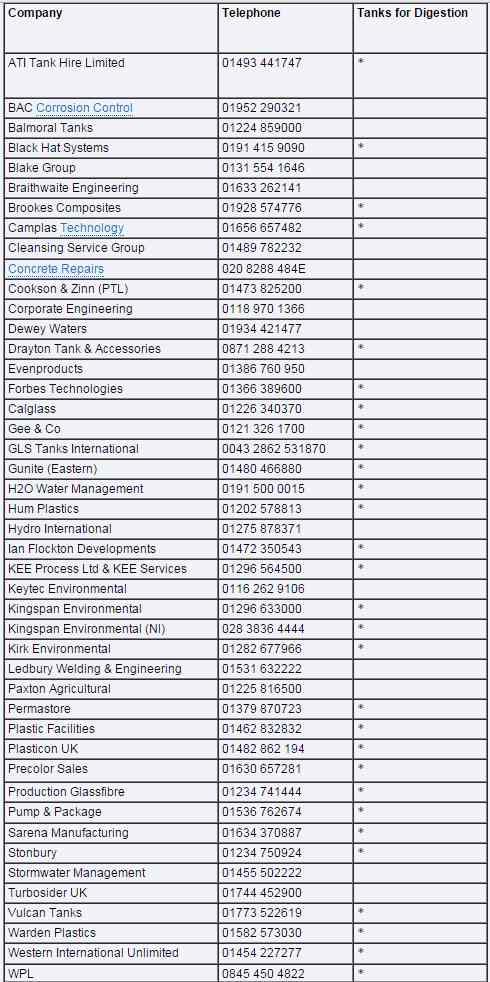

UK Anaerobic Digestion Tank Contractors

Large numbers of these types of anaerobic digestion tanks have been built in large commercial scale sizes in the UK by the following contractors:

- Galglass

- Permastore

- A-Consult

- Aquastore

and others. See our list below for the top UK anaerobic digestion tank contractors for large commercial scale digesters:

List of UK Tank Suppliers for Digesters and Generalanaerobic-digestion.com/free-list-uk-anaerobic-digestion-plant-contractors Use

This List of UK Tank Manufacturers and Telephone Numbers was current in August 2009.

This table is based upon a table published in the August 2009 edition of Water and Wastewater Treatment, as the Tank File. For the full table which contains far more information on each supplier subscribe to the magazine or visit their web site at http://www.water-waste-environment-marketplace.com/index.asp

Small and Micro-Scale Anaerobic Digestion Tanks

For smaller applications, such as households or farms, various innovative materials and techniques come into play. Here are some noteworthy options:

- GRP (Glass Reinforced Plastic): Lightweight and resistant to chemicals.

- HDPE (High-Density Polyethylene): Flexible and durable, ideal for small tanks.

Innovative Materials like GRP and HDPE

GRP and HDPE offer distinct advantages in small-scale setups requiring no coatings for preservation. They are easy to handle and can be molded into various shapes. This flexibility makes them suitable for different site constraints and reduces installation time.

Construction Techniques in Developing Nations

In many developing regions, cost-effective construction techniques are vital for creating anaerobic digestion tanks. These techniques often include:

- Using locally sourced materials to minimize costs.

- Employing community labor to improve local skills.

- Adapting designs to fit local environmental conditions.

By focusing on practical solutions, communities can effectively implement anaerobic digestion systems to manage waste and harness energy.

Exploring the Future of Anaerobic Digestion Tank Design

Advancements in Material Science for Biogas Tanks

As we look ahead, material science is playing a crucial role in the design of anaerobic digestion tanks. Innovations are shaping how these tanks are built, focusing on improving durability and efficiency. Here are some key advancements:

As we look ahead, material science is playing a crucial role in the design of anaerobic digestion tanks. Innovations are shaping how these tanks are built, focusing on improving durability and efficiency. Here are some key advancements:

- Composite Materials: Combining different materials to enhance strength and reduce weight.

- Smart Materials: Materials that can respond to environmental changes in real-time.

- Eco-Friendly Options: Biodegradable materials that reduce environmental impact.

Future Trends in Anaerobic Digestion Technology

Looking at the future, several trends are emerging in anaerobic digestion technology. These trends focus on increasing efficiency and sustainability while addressing common challenges. Here are some notable trends:

- Modular Designs: Tanks designed for easy expansion as needs grow.

- Waste-to-Energy Systems: Integrated systems that convert waste into usable energy.

- Monitoring Technologies: Enhanced sensors for better performance tracking and management.

Recommendations for Selecting the Right Anaerobic Digestion Tank

Factors to Consider When Choosing a Tank

Selecting the right anaerobic digestion tank is essential for maximizing output and minimizing issues. Several factors can influence your choice, including:

- Size and Capacity: Determine the volume of waste to be processed.

- Material Type: Choose between steel, concrete, or innovative materials based on your needs.

- Location: Consider local regulations and environmental conditions.

Best Practices for Installation and Maintenance

Proper installation and maintenance are vital for the longevity of anaerobic digestion tanks. Here are some best practices to follow:

- Professional Installation: Always hire experienced contractors for setup.

- Regular Inspections: Schedule frequent evaluations to identify issues early.

- Maintenance Training: Educate your team on routine maintenance tasks.

Engaging with the Anaerobic Digestion Community

Resources for Contractors and Users

Being part of the anaerobic digestion community can be incredibly helpful. There are numerous resources available to contractors and users alike, including:

- Industry Associations: Join groups that focus on renewable energy and waste management.

- Online Forums: Participate in discussions and share experiences with peers.

- Workshops and Webinars: Attend events to learn about the latest technologies and practices.

How to Stay Updated on Industry Developments

Staying informed about changes in the anaerobic digestion field is essential. Here are some ways to keep up-to-date:

- Subscribe to Journals: Read publications dedicated to renewable energy and waste management.

- Follow Influencers: Connect with industry leaders on social media.

- Join Networking Events: Meet others in the field and share insights.

Final Thoughts on Anaerobic Digestion Tanks

Summary of Key Insights on Tank Selection and Usage

In summary, understanding the various aspects of anaerobic digestion tanks is crucial for successful implementation. Key considerations include material choice, tank design, and ongoing maintenance. By focusing on these factors, you can enhance efficiency and sustainability in your projects.

[Article first published on 13 November 2014. Rewritten November 2024.]

I have read this post and if I could I wish to suggest you few interesting things or tips. Perhaps you could write next articles referring to concrete block tanks. i do not see the article for concrete tanks for Bangladesh. I wish to read more things about it!

Good writing. We supply post tensioned precast wall units for biogas disgester tanks. I do not see these in your concrete tank write-up here. Post-tensioned units are low cost and quick to erect. They weigh less than the type you show. I suggest post-tensioned precast units for a good digester and low-cost in the tank construction.

Had to compose a few words, to thank you regarding the issues you’ve talked about here. Very useful for my contractor meeting next week. Thanking you!

I went over this internet site and I did conclude that you have a lot of fantastic information, saved to favorites (:. Can you add more about small biogas plants soon though?

Definitely very helpful for a website. This is an important issue for us. Our tanks for our project must last a very long while and never leak. This is vital. Thanks

Is a septic tank the same as an Anaerobic Digestion Tank? I can’t get over how great this site is. You keep up the good work.

WONDERFUL Post. Thanks for share..

That is a good tip especially to those new to the blogosphere. Brief but very accurate info… Many thanks for sharing this one. A must read article!

Best regards :