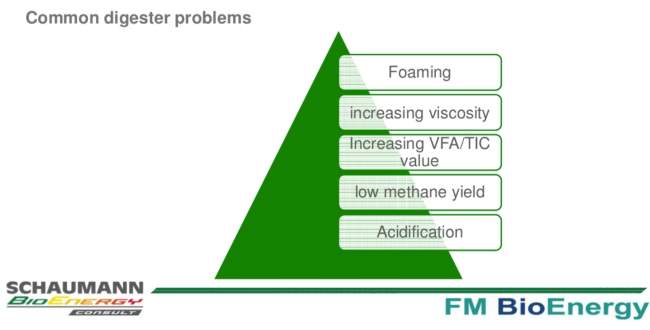

We list 5 anaerobic digestion problems which are common to the biogas process, and are easily and rapidly corrected for and avoided, at AD facilities run by expert biogas plant operators.

BUT, the same problems can be disastrous/ cause long digester-downtime in the hands of novice Anaerobic Digestion Plant operators.

The 5 Anaerobic Digestion Problems, are:

- Foaming

- Acidification

- Increasing Viscosity

- Increasing VFA and TIC Value

- Low Methane Yield

Biogas plays an increasingly important role as a renewable, store-able, 24/7 energy source. Anaerobic digestion (AD) is the process used in biogas production. Most anaerobic digestion problems are routinely avoided by careful plant operation by experienced staff using their knowledge on the suitable choice and, if necessary, mixing of feedstocks. Nevertheless, it is useful to all AD industry participants that the main anaerobic digestion process problems are documented, and we have endeavoured to provide an accurate summary of the main problems in this article, as follows:

1 – Foaming

Anaerobic digestion foaming is one of the most common anaerobic digestion problems. It is an operational problem in biogas plants with negative impacts on the biogas plant's economy and environment. A survey of 16 Danish full-scale biogas plants for foaming problems, revealed that most of them had experienced foaming in their processes for up to three times per year.

Foaming incidents often lasted from one day to three weeks, causing 20-50% biogas production loss. One foaming case history has been reported at a biogas plant indicated that the combination of feedstock composition and mixing pattern of the reactor was the main cause of foaming.

Foaming incidents often lasted from one day to three weeks, causing 20-50% biogas production loss. One foaming case history has been reported at a biogas plant indicated that the combination of feedstock composition and mixing pattern of the reactor was the main cause of foaming.

How to Cure Anaerobic Digestion Foaming: Strategies and Best Practices

Foaming in anaerobic digestion systems can be a significant operational challenge, leading to reduced process efficiency, potential environmental issues, and safety concerns.

The phenomenon typically occurs when gas bubbles are trapped in a thick layer of scum on the surface of the digester. This can be caused by a variety of factors, including substrate composition, microbial activity, digester design, and operational conditions. Effective management and mitigation of foaming are essential for the smooth operation of anaerobic digestion facilities.

Understanding the Causes of Foaming

Substrate Properties: High protein or lipid content, the presence of surface-active agents, and rapid biodegradability can predispose substrates to foaming.

Operational Conditions: Overloading, rapid changes in feedstock composition, temperature fluctuations, and inadequate mixing can all contribute to foaming.

Biological Factors: Certain microbial populations or activities, such as the proliferation of filamentous bacteria, can lead to increased foaming tendencies.

Mechanical and Design Issues: Inadequate or ineffective mixing, poor digester design, and mechanical malfunctions can exacerbate foaming issues.

Strategies for Prevention and Mitigation

i. Operational Adjustments

Feeding Strategy Optimization: Implement a gradual and controlled feeding strategy. Avoid sudden changes in substrate types or loading rates.

Temperature Regulation: Maintain a stable thermophilic or mesophilic temperature regime to prevent thermal shocks.

Mixing Efficiency: Ensure proper mixing to avoid stratification but avoid excessive agitation which can incorporate more gas into the foam.

ii. Substrate Management

Pre-Treatment: Alter the physical or chemical characteristics of feedstock prone to foaming through processes such as hydrolysis or dilution.

Diversification of Feedstock: Mixing different substrates can balance out properties that contribute to foaming.

iii. Biological Control

Microbial Population Management: Monitor and control the growth of filamentous bacteria or other microorganisms known to cause foaming.

Additives and Inhibitors: Utilize anti-foaming agents cautiously, as they can be a temporary solution and may affect the digestion process.

iv. Design and Technical Solutions

Improvement of Digester Design: Optimize digester configuration to facilitate better gas release and reduce dead zones.

Foam Detection and Control Systems: Implement automated foam detection and control systems for early intervention.

v. Monitoring and Analytics

Regular Sampling and Analysis: Conduct routine monitoring of digester contents for indicators of foaming potential.

Data-Driven Decision Making: Utilize data analytics to understand trends and triggers of foaming in your specific system.

Foaming Prevention and Cure – Summary

Foaming in anaerobic digestion is a multifaceted issue requiring a comprehensive approach. Prevention is often more effective than treatment. Regular monitoring, operational adjustments, careful substrate management, and effective digester design are key to controlling foaming.

When deploying anti-foaming agents or other additives, it is crucial to consider their long-term impact on the digestion process and end-product quality.

A deep understanding of the specific causes and dynamics of foaming in your facility will guide the development of a targeted and effective digester foaming management strategy.

2 – Acidification

This second of our listed anaerobic digestion problems is more correctly referred to as “over-acidification”, because acidification is in itself an important stage in healthy anaerobic digestion.

It is one of the most expensive problems. When the digester biology is “over-acidified”, the effect can take months until the digester biology recovers, performance is restored. Throughout that period the biogas output will be reduced, and the operator must anxiously wait for the expected revenues to flow again.

To avoid over-acidification it is important to control the digester biology continually, and to react to early-signs of problems quickly and in the correct way.

Nearly always an overload of the digester biology is the cause for an acidification. Operators should not assume it is simply the loading rate which is the cause. Frequently, the problem has nothing to do with the loading rate of the digester, and other factors are the root cause.

It has been reported that the overload can be started by the following factors:

- Overfeeding of the digester or too widely fluctuating substrate quantities.

- Fluctuations of the temperature, which can inhibit the biological activity of the bacteria.

- A lack of micro- and/or macronutrients limiting the biological growth/ metabolic rate of the bacteria.

- An inadvertent addition of toxic substances, effectively inhibiting the biological activity of the bacteria.

The overload is in such circumstances caused by the fact that the methane bacteria are unable to grow fast enough to degrade the substrate to biogas.

The cause for the slow-down in growth of the methane bacteria needs to be identified to ensure the right corrective action or extended delay in the recovery of the plant's methane output will ensue.

On occasions excessively high concentrations of ammonia can also inhibit methane producing bacteria, but this is one of the possible anaerobic digestion problems which should be designed-out within the process design stage. – source generally via friedmann-biogaspraxis

3 – Increasing Viscosity

Increasing viscosity when using corn silage as a main feedstock has been reported as causing this problem, but it occurs with other silage types as well.

It is reportedly most common when the optimum harvesting time is missed due to poor weather conditions. This can lead to silage corn stocks that are over-matured. High starch levels can be present, which can add to the problem.

The use of these silage types causes problems in biogas production plant. Floating layers form and flow and pump properties deteriorate.

In addition to poor material transport and defective degassing, this often also leads to elevated plant energy consumption and increasing wear and tear on agitator/ mixing equipment. In extreme cases, major faults or production outages can occur. via DSM Biogas

Diagnosis and Remediation of Increasing Viscosity in Biogas Plants

The phenomenon of increasing viscosity in biogas plants can significantly impede the efficiency of the anaerobic digestion process, leading to operational difficulties.

This issue often results in poor mixing, reduced biogas yield, and can cause mechanical failures. Addressing this challenge requires a methodical approach to diagnosis followed by targeted remedial actions.

Diagnostic Approach

- Substrate Analysis: Evaluate the physical and chemical properties of the feedstock. High solids content, particularly of lignocellulosic materials, can increase viscosity.

- Process Monitoring: Regular monitoring of key operational parameters such as temperature, pH, and mixing efficiency. Sudden changes in these parameters can indicate issues leading to increased viscosity.

- Digester Performance Assessment: Analyze the biogas output, composition, and digester content homogeneity. Reduced gas production or changes in gas composition can be symptomatic of viscosity issues.

- Microbial Activity Check: Examine the health and composition of the microbial consortium. Imbalances in microbial populations can impact the digestion process, influencing viscosity.

Remediation Strategies

Adjusting Substrate Composition

- Dilution: Introduce water or less viscous material to reduce overall viscosity. This should be done carefully to avoid diluting the nutrient content excessively.

- Feedstock Pre-treatment: Employ mechanical, thermal, or chemical pre-treatment methods to break down complex substrates and reduce viscosity.

Optimizing Operational Conditions

- Temperature Regulation: Ensure optimal temperature is maintained. Mesophilic and thermophilic conditions can have different impacts on viscosity.

- pH Management: Maintain a neutral to slightly alkaline pH to facilitate microbial activity and reduce viscosity.

Enhancing Mixing Efficiency

- Improved Mixing Mechanisms: Upgrade or adjust mixing systems to ensure homogenous substrate mixing without creating dead zones.

- Intermittent Mixing: Implementing intermittent mixing strategies can reduce power consumption while maintaining homogeneity.

Microbial Management

- Microbial Additives: Introduce specific microbial cultures or enzymes to enhance the breakdown of viscous components.

- Balancing Microbial Population: Adjust feedstock or operational parameters to promote a microbial balance conducive to lower viscosity.

Regular Monitoring and Feedback

- Implement a Feedback Loop: Utilize data from regular monitoring to continuously adjust operational parameters for optimal performance.

- Advanced Analytics: Use data analytics tools to predict and prevent viscosity issues based on trends and patterns.

Increasing Viscosity Conclusion

Managing increasing viscosity in a biogas plant is a complex task that requires a holistic understanding of the system. A combination of substrate management, operational optimization, mechanical adjustments, and microbial balancing is typically required to effectively address this issue.

Regular monitoring and proactive interventions based on data analysis are key to maintaining optimal viscosity and ensuring efficient biogas production.

4 – Increasing VFA and TIC Value

An increasing VFA (Volatile fatty acids) and at times also in the TIC (Alkalinity, total inorganic carbonate buffer) value, may occur when the organic loading rate (OLR) is increased above a long-term stable rate. The biogas process becomes unstable, due to accumulation of volatile fatty acids (VFA), and/ or a non-optimum elevated (alkaline) pH.

When the anaerobic digestion (AD) of biowaste is impaired it is the accumulation of volatile fatty acids (VFA) which in itself is cited as the cause of a process slow-down resulting in further VFA accumulation in a worsening cycle, unless the OLR is reduced.

5 – Low Methane Yield

Lower than anticipated methane yield is very often the first indication of other problems, so it is important to continuously monitor the percentage of methane and other gases such as hydrogen sulphide (H2S), as an early-warning of the need to make adjustments to the digester operation.

Low methane yield is a symptom of other problems, and is only included here for completeness.

When methane yield drops, the operator should investigate the first four of the above five problems to find the underlying cause of the low methane yield.

Conclusion – Anaerobic Digestion Problems Seen in Commercial Biogas Plants

The two most common anaerobic digestion problems that occur during this bio-technological process in practice are, foam formation, and over-acidification.

The first is the least serious and can often be rectified in the short term by the use of certain chemical additives, and in the longer term by modifying the feedstock and/ or improving mixing/ stabilising digester conditions and other measures to reduce stress on the digester biology.

Although foaming may be a symptom of other more intractable problems, over-acidification can take the longer time of these two most common anaerobic digestion problems to correct and as a consequence of that, result in the biggest loss of biogas income.

The moral of this article for new commercial biogas plant operators, to take-away with them, is the fact that going it alone, and not taking expert advice until you have gained your own practical experience – when biogas/ anaerobic digestion problems occur – can be a very expensive decision to take.

Install good quality gas monitoring equipment and take expert anaerobic digestion process operational advice, in the initial months and years of biogas plant information. In that way there is no reason why biogas plants cannot be operated very successfully with very low-downtime rates.

Additional Sources:

a) Article inspired by: Dr Thomas Fritz, Schaumann Bioenergy, Presentation to the ADBA, AD and Biogas Conference 2015, via http://adbioresources.org/purple-day-one

b) https://link.springer.com/article/10.1186/s13705-016-0095-7

c) http://euagrobiogas.rtd-services.com/images/7.pdf

Disclaimer: The author is not a biogas process expert. This article has been compiled from online research, and should be regarded as no more than entertainment. As elsewhere on this website, no liability will be accepted for any loss arising from any action or inaction as a result of this article, or related videos. The reader/ viewer must make their own research and take action based upon that work alone.

[First published 17 January 2018. Updated 4 November 2023.]

This is very informative and good work for references.

To evaluate the feasibility of a planned biogas facility, one of the first questions is will there be enough methane, is the potential there in the local area?

Here are my, basic considerations for designing an anaerobic digester. First, you know the temperature of the ambient air. You know the temperature you want to operate the reactor at. For example, it might be in the range known as mesophilic. Select your solid’s retention time based on your treatment objectives. You should already know your loadings. What’s gonna be put into the reactor day by day.

Then decide on the total solids concentration, and mass loading of the sludge. You should also know have researched the degradability of the sludge. Based on this data, I presume you can calculate the reactor volume. Also, finally, you can also do sums to calculate the amount of biogas that will be produced, including the methane concentrations. From this see whether you think the business looks profitable

This is a topic that is close to my heart… Thank you!

The RHI only provides a small incentive to the supply of renewable heat through the combustion of biogas even if you can get it. Plus to be able to install CHP, so will still be driven by the availability of suitable local heat users and the associated costs of getting the supply to them.

Heat recovered from a CHP unit associated with an AD facility that is used to provide heat for the AD process itself does not count towards the RHI. This disadvantages AD operators in the colder North.

It’s a black art. Sounds sinister I know, but what I mean is that substrate just is so black in the tanks. It’s the art of substrate to digestate management. Keep-on rubbing me the right way, and you might get a genie.

Jo – Top marks for the most wacky comment I think I’ve had yet! I’m not sure what your point is?

So many problems. It must be a minefield. Thanks for sharing such a good piece of writing. It is good, that’s why i have read it fully. Please show my link.

They can sell the waste CO2 back to the environment food producers. Maybe also sell them some of the fertiliser. They can truck this on the return journey, when they drop off the waste organic matter. That way the process becomes even more affordable :) Keep up posting these articles. Unique website!

Any chance you can get some catylitics from sassol and make wax or diesel maybe even petrol? using fishertophic proces and your biogas?

Thanks a lot for all the details. Sounds awful what can go wrong. But, take advice and these plants will be great.

Respect to the website author, some wonderful entropy reversal is this.