Pig farm anaerobic digestion and including in this swine, and hog farms have just as much potential as Dairy Farms for anaerobic digestion to make biogas as an additional source of income.

At the same time, their biogas plants can provide for a much more environmentally beneficial means of disposing of the farm waste, and work in harmony with global goals toward reducing carbon emissions.

On This Page:

- Making Biogas Energy from Piggery Waste

- Want to lower the energy bills in your business?

- Waste to energy solutions for piggeries

- A Bioenergy Solution for Swine Farms

- Performance of Anaerobic Lagoons for Gas Production

- How to Make Biogas

- Piggery waste a valuable resource

- Treating piggery waste using microalgae

- Turning wastewater into a valuable resource

Making Biogas Energy from Piggery Waste

The installation of a biogas plant is essentially an exercise in making renewable biogas from piggery wastewater, while the nutrients in the output are put to good use as fertiliser. It is not an easy project to undertake and succeed with and yet many have done it successfully already, and many will follow.

Biogas production is a good way to reduce waste in our society and, as a result, reduce the emission of harmful greenhouse gas emissions that affect the atmosphere and cause many environmental problems such as global warming. Furthermore, using waste to generate methane gas will help to reduce many of the diseases caused by pollution problems.

Nebraska's first On-Farm Generator is powered by methane produced by an anaerobic digester of swine manure. Danny and Josie Kluthe of Dodge, Nebraska, operate the farm, and the alternative enterprise is known as Olean Energy.

Their main disadvantage for swine manure treatment is the required operator skill level to know when and how much to feed. UASB digesters have been used in a number of piggeries where the uneven solids flow from flushed or pull-plug barns is difficult to control. Fixed film reactors have been used successfully in agriculture, but solids separation is required prior to digestion.

Depending on the size of the hog, hogs produce between 2.3 and 13.1 pounds (lbs) of manure per day. According to U.S. Department of Agriculture data on NC hog populations and weights from March 2018, this herd of pigs generates more than 8.7 million tonnes of manure per year.

Hog manure, as excreted, contains approximately 90% moisture and 7% biodegradable (or volatile) solids. A 150-pound hog's manure has a biogas generation potential of 4.8 cubic feet (ft3) per day. After adjusting for energy consumption for digester heating and pumping, the net yield for each hog is around 3.2 ft³/day.

Capturing the biogas yield potential of that much swine manure wastewater volume would necessitate very large and numerous reactor tanks, so lagoons have typically been lined with high-density polyethylene (HDPE) liners. While anaerobic lagoons may appear to be a much more cost-effective approach at first, problems often arise after a few years when these lagoons become clogged with silt and grit. They are hard to clean due to their size and are costly to dig out.

Complete mix systems (CSTRs) are far better for swine farms and are the second most common AD system for swine manure currently in use. There are approximately 18 of these systems in operation in the United States, accepting manure from approximately 160,000 head of swine. 5 In the Midwest, complete mix systems are mostly found on smaller, single-farm operations.

The most common AD technologies for treating swine manure are, we believe, typically covered lagoons and complete mix systems.

However, other process variations may be better for the high dilution of the organic matter in pig manure. See the sections below “Turning wastewater into a valuable resource” for more about these less well-known AD processes, and how to make biogas.

Want to lower the energy bills in your business?

Remley Farms in Pennsylvania, according to the EPA website, digests up to 9,000 gallons of hog manure and 2,000-3,000 gallons of food waste per day.

The addition of food waste may increase the system's electricity output by a factor of two. Where technically feasible, hog farm digestion operations perform well by producing other products in addition to biogas and biomethane, such as concentrated nutrient fertilisers. This increases revenue or directly reduces the cost of bagged chemical fertilisers by using the fertiliser on the farm.

In one case study, we saw recently it was stated that the system meets all of the farms' energy needs, with excess sold to the grid, saving the company about $29,000 per month in power and gas bills and earning $5,700 per month from excess power sold to the grid.

Waste to Energy Solutions for Piggeries

Hog manure works well compared to other manures. However, because swine manure contains more water, swine manure digesters are relatively large in comparison to the amount of organic matter added. This means that OLR and VRE levels are lower than in digesters treating thicker manure.

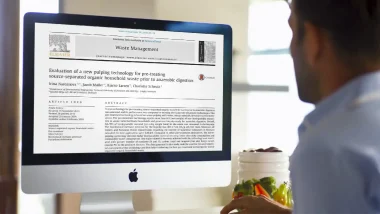

The cooperative research centre for high integrity Australian Pork (Pork CRC) has invested $300,000 with the algae research and development centre at Murdoch University to investigate the use of algae. The intention is to cut costs, recover energy from waste and reduce the potential for groundwater contamination at piggeries.

The state of North Carolina has all the ingredients to move the biogas needle on pig manure biogas production. All raw manure is organic waste that needs alternative management solutions. A renewable energy portfolio standard with heat recovery for swine waste-derived energy, and pioneering gas production projects that are paving the way for those that follow.

A Bioenergy Solution for Swine Farms

Investing in biogas upgrading equipment to make RNG and a swine farm can gain a better, more reliable, return on the biogas produced than by selling the biogas energy as electricity.

In some US states, Renewable Identification Numbers or LCFS credits can also be generated by RNG. As a result, the majority of swine projects currently in development intend to produce RNG.

To reduce their carbon footprint, many businesses and utilities are willing to pay a premium for renewable energy or carbon offsets by setting up strategic alliances.

Biogas producers who collaborate with an organisation to purchase the gas may be able to increase their profits. Google, for example, contributed to the operation and maintenance costs of Loyd Ray (PDF Farms AD for carbon credits.

Performance of Anaerobic Lagoons for Gas Production

AD lagoons across America cool down in the autumn, and production drops almost to zero in the winter, with much of the fertiliser value remaining in the lagoon with sludge.

However, if the primary energy requirement is summer ventilation and the farm lacks land to recycle nutrients, this may be the best option.

While producing on-farm energy, anaerobic digesters reduce farmstead odours and reduce the carbon footprint of pork production. However, hog farmers face a significant challenge when it comes to digestion. Because of the low volumetric methane yield of swine manure, hog farms would have large, inefficient digesters.

That's if no special hog waste treatment digester design measures are taken. Pork producers normally overcome this barrier by using high rate digesters, though their operation is more volatile than CSTR type digesters.

How to Make Biogas

High-rate UASB reactors with hydraulic retention times as short as 2 hours can be used for anaerobic digestion of particle-rich supernatant from cow and pig manure, and the process is well suited for on-farm manure treatment. Pig manure contains a lot of ammonia.

This could be a problem in anaerobic treatment because high ammonia concentrations can inhibit methanogenesis, resulting in low biogas yields. This is well established, despite the fact that adaptation of the anaerobic microbial community over time has been shown to increase ammonia tolerance.

Piggery waste a valuable resource

Pig manure produces the same amount of CH4 as any other manure, pound for pound. To put it another way, swine manure has a high specific methane yield. The issue is how we handle pig manure from hogs when it is wetter than that from cattle, sheep, horses, and poultry.

Imagine if wastewater, one of the major waste streams from pig production, could be utilised as a valuable resource, rather than merely a nuisance to be dealt with carefully and at considerable expense.

Methane emissions from crops used for feed all the way to the consumption of our hogs account for 40% of a farm's carbon footprint. To achieve a 25% reduction, 90% of finishing animals in North Carolina, Virginia, and Utah will need to be on biogas-based systems by 2028.

Treating piggery waste using microalgae

The onsite use of anaerobic digestion for treating piggery waste not only generates renewable energy but is also a sustainable waste management solution.

Ammonium nitrogen removal in batch cultures treating digested piggery wastewater with microalgae Oedogonium sp.

Turning wastewater into a valuable resource

On hog farms, the anaerobic digestion process must be designed to reduce HRT while maintaining SRT long enough to sustain the microbial communities. This is what drives the demand for high-rate digesters. Digesters such as fixed-film, Anaerobic Sequencing Batch Reactor (ASBR), and Upflow Anaerobic Sludge Blanket (UASB) types work well with dilute hog manure.

They raise maintenance costs above anaerobic digesters operating as a standard CSTR and necessitate a reasonably skilled operator. However, with the proper level of continuous attention, they work. Needless to say, when it comes to hog manure, it is always a good idea to add a co-digestion input with a high volumetric methane yield to the feedstock to boost biogas production.

Concluding: Biogas Production from Pig Slurry at Swine Operations

Although poultry manure from these farms is easily used as organic fertiliser for cash crop production, pig manure is typically washed and discharged, with or without treatment, into nearby streams and rivers.

Efficient wastewater treatment from pig farms with limited land is very expensive because it usually necessitates some degree of artificial aeration.

It is critical to evaluate the technical and economic feasibility of converting pig farm biogas into electricity; the following challenges apply to swine manure digestion:

- The organic content of the wastewater generated by pig farms is far below what is required for efficient CSTR biogas production. Therefore, more innovative treatment technologies will be needed such as USAB, fixed-film bioreactors etc.

- The potential amount of electricity generated by such a project may not always match the farm's daily fluctuating electricity demand.

- Current government policies and infrastructure support to repurchase excess electricity generated by such a project are insufficient.

- a misconception is held by some farmers that recovery of biogas from an anaerobic lagoon digester will enhance the efficiency of wastewater treatment to the point of improving the quality of their wastewater at the discharge point to meet the governmental requirements for discharge; and

- sharing of the carbon fund by farmers and the carbon credit trading company may help profitability but isn't available everywhere.

In this archive section, we rounded up some of the recent articles posted on the subject back in 2016. We think that they are still relevant today.

They show just how global the subject of pig farm anaerobic digestion has become.

It is our view that, while most on-farm biogas plants built to date have focused on using, maize, dairy wastes, and especially manure, as their source of feedstock, many other waste feedstocks remain underrepresented.

Piggery waste is one example in which there is huge potential for biogas production.

Pig Manure Digestion with Thermal Pre-treatment and Separation

Analyses of pig manure have shown a large untapped potential exists to promote an abiotic economy in the pig farming industry. A study has demonstrated that the digestion of this waste material is highly stable.

In particular, there is room for many more developments in swine farm anaerobic digestion, using waste biomass from piggeries (hog production) and meat production waste. There are many benefits from this, and AgSTAR, the US government USDA funded research body has been pointing them out, as in the article extract that follows:

AgSTAR Encourages Pig Farm Anaerobic Digestion

AgSTAR, the biogas recovery division of the U.S. EPA, noted that [ pig ] hog farms have a great potential to benefit from anaerobic digestion.

Anaerobic digestion is an important technology across a wide range of industries. Meat producers [and piggeries] in particular are increasingly adopting it because it helps operations both dispose of waste and become more energy-efficient.

Anaerobic digestion is used to extract biogas — a mixture of methane and carbon dioxide — from organic wastes. Digestate, a byproduct of the anaerobic digestion process, is a stable, fermented waste that can be reused as a fertiliser.

Organic wastes from food and beverage processing are especially suitable for waste-to-energy treatment. Waste streams may include process wastewater, whey, primary sludge from wastewater pretreatment, and manure, as well as slaughterhouse wastes and many other biosolids.

Anaerobic digestion is an important technology for effective, efficient food production. With it, users can reduce water consumption, reduce waste, and generate energy. There is also the potential for saving money and, in some cases, creating new revenue streams. When combined with other technologies, anaerobic digestion, waste-to-energy treatment, and biogas production can be very cost-effective and environmentally friendly solutions even for the most difficult-to-treat waste streams. via RWL Water

Clearly, AgStar's message was not needed before one Australian swine farm anaerobic digestion project, went ahead. Construction is already well advanced on their new renewable natural gas piggery biogas plant, as follows:

Piggery Waste to be Feedstock for Australia's First Biogas Digester Facility

WA pork producer set to use poo to power piggery as Australia's first biogas digester facility. Construction has begun on what is thought to be Australia's first piggery to run electricity from an on-site farm biogas digester facility.

GD Pork was granted approval for a $14.5 million expansion to their Kojonup renewable energy facility, 250 kilometres southeast of Perth, in August last year. The expansion is expected to allow for site production to increase by double, to about 75,000 pigs a year.

But, the increase in production has led the company's managing director Torben Soerensen to look for new ways to supply the site with power.

“We're putting in an anaerobic digester tank, so basically a big tank where the waste from the pigs can go in,” he said. “The bacteria break it down [and] that creates methane which is then put into generators and it can create electricity that way.” The biogas facility is anticipated to enable the site to be fully self-sufficient.”

However, he said what they did not use would be burned off as gas instead. Mr Soerensen, who is originally from Denmark, said the use of biogas facilities was big in other parts of the world but had not yet been picked up in Australia:

“It's not a new technology; it's been used overseas for the last 20 years,” he said. “There have been similar systems [in Australia] where they do it in covered ponds, but this is the one where it's actually a digester itself.”

He said it would be cost-viable for most West Australian piggeries:

“It will save us on electricity, but it also has some investment costs involved so at the end of the day, it's not good business; it's not why we do it”, he said. “Waste is obviously an issue with piggeries and if you don't do anything, you just stockpile your waste.” “It's a nuisance for neighbours and smells.” “By putting it through that process, you also eliminate the smell from the waste so that's a big plus.” “Then it just makes sense because otherwise, we would have to generate electricity from diesel, and if you look at it that way, then, of course, it's saving us money.”

The facility is expected to be operational by the end of the year (2016). via abc.net.au

Meanwhile, in the UK, a scientific study has revealed that:

Anaerobic digestion reduces pathogens in casualty pig carcases

Anaerobic digestion (AD) can significantly reduce pathogens in pig carcass material (PCM), according to new research at Harper Adams University.

The research also showed that bio-reduction through AD could provide a solution to on-farm storage or disposal of pig carcase material which could reduce the costs of fallen stock collection and reduce vehicles driving between farms.

The first stage of the research established that the AD process could significantly reduce the number of particularly resilient pathogens in PCM and that it can generate considerable quantities of biogas.

The second stage, funded jointly by Defra and BPEX, is aimed at reducing fossil fuels by helping towards AD being used as a self-sustaining on-farm biogas system for storage or disposal of PCM.

Before being developed commercially, AD must provide a positive outcome which can then be approved by the EU.

via Anaerobic digestion reduces pathogens in casualty pig carcases

Finally, a swine farm anaerobic digestion plant has been commissioned in Croatia:

WELTEC Completes Swine Farm Anaerobic Digestion Biogas Plant in Croatia

German anaerobic digestion and biogas plant manufacturer, WELTEC BIOPOWER, has commissioned a 250 kW facility at a pig farm in Varazdin, Northern Croatia.

According to the manufacturer, the farm waste processing plant perfectly suits the farm's cycle of food production from the liquid manure produced by around 3000 pigs.

WELTEC explained that even before joining the EU in 2013, Croatia had committed itself to the EU climate protection goals in order to establish the preconditions for obtaining subsidies for decentralised energy projects in rural areas.

With these grants and fixed feed-in tariffs for green power, the country’s government intends to increase the share of renewable energy by about 30% by 2030.

The framework conditions for this were said to be excellent, as Croatia has a healthy supply of biomass – one of the country's most important renewable energy sources.

Like a Pig in Muck

The German firm explained that for this project pig breeder Dalibor Vrček's family-managed farm also had ideal conditions for establishing a synergy of animal husbandry and biogas generation.

In addition to the subsidy for the construction, the operator was able to base his investment decision on a fixed feed-in tariff of € 0.19 per kilowatt-hour of power fed in over the next 14 years.

According to WELTEC, this income forms a solid basis for diversifying the farmer’s business. via WELTEC Completes Swine Farm Anaerobic Digestion Biogas Plant in Croatia

There appears to be a big potential for many more hogg farm anaerobic digestion plants in the near future, around the world.

Thank you very much

Hi, You have completed an outstanding job. Did you see the Pepper Pig cartoon on compost making. It’ childs play! Hoot! Woot!

I do adopt a positive attitude, but within an electric connection possible, I don’t see what to do in summer, instead of flaring it up. Winter’s fine as we can heat the barns and house.

I would like to contest the statement “First Anaerobic Digestion Plant in Australia”. That can’t be right! There MUST have been earlier biogas producers. Thanks for the concepts you talk about through this website.