In the Anaerobic Digestion Plant Design section, we provide the following articles:

In the Anaerobic Digestion Plant Design section, we provide the following articles:

Anaerobic Digestion Process Nutrients

Anaerobic Digestion Costs

Anaerobic Digestion Biomass

Anaerobic Digestion Feedstock

An Introduction to Anaerobic Digestion Plant Design

The first stage of any AD Plant design is to define the primary aim, or purpose which an AD Plant is intended to satisfy.

Setting the Brief for an Anaerobic Digestion Project in Municipal Solid Waste Treatment

The main purpose for Anaerobic Digestion in MSW Treatment may be, for example, to reduce the bulk (or “mass”) of the material.

The new generation of MSW anaerobic digesters is being designed with the following additional design features:

- Biogas biofuel production; which can be burned for electricity production, etc

- Sanitization: due to the AD Process's ability to operate at raised temperatures (usually using the biogas produced by the process) during the reaction, to ensure compliance with Animal By-Product Regulations (ABPR)

- Producing a digestate comprising a fibrous material, which can be spread on land, co-disposed with compost, or incinerated, and a liquor, which (with care) can be used as a liquid fertiliser, but often must be further treated.

Anaerobic Digestion Design

The terms anaerobic digestion design and biogas digester are synonymous. However, on this website, we have chosen to use the term anaerobic digestion plant design as a more generic term.

This is because the term “biogas” suggests that the plant’s primary purpose will be to produce biogas (methane), and there are many anaerobic digestion plants both in use today and historically that have not been installed primarily to produce and utilise biogas (methane for electricity generation, biofuel for transport vehicles, LPG for cooking and heating use etc,).

Anaerobic digestion design also encompasses plants, which are primarily designed to:

- Treat an effluent (as in industrial effluent treatment) to a quality which will allow it to be discharged to a sewer or a watercourse according to the requirements of the site owner and the regulatory authorities;

- Treat the secondary (sludge) by-product from a water treatment process to reduce volume, sanitise, and permit final disposal (eg to land); as in the digestion of sludge created during the popular (aerobic) activated sludge sewage treatment process;

- Treat Solid Waste (as in Municipal Solid Waste (MSW)) to primarily help meet local government targets (especially within the European Union (EU)) where strict targets must be achieved by member states to divert the overall tonnage of MSW away from landfill, and also to reduce still further the amount of organic/biodegradable content within the waste which is sent to landfill.

It is only since about 2003 in Europe, but possibly a century earlier in China, that the creation of biogas has been a viable function of anaerobic digestion plants. The reason that AD biogas has now become a valued commodity is that fossil fuel sources of methane gas have risen so much in price that (with some encouragement from government grants and tax breaks) biogas methane can be cheaper.

Biogas is, when scrubbed and pressurised, equivalent in composition and broad calorific value to the fossil fuel known as Liquid Natural Gas (LNG). At higher pressures, it can double for Natural Gas in town and city gas supply pipelines.

Just as the primary purpose, and scale, of anaerobic digestion plants are very diverse, so are the processes that have been developed to meet these challenges.

Many processes are similar in principle but do vary substantially according to the primary purpose and environmental, plus economic and political drivers.

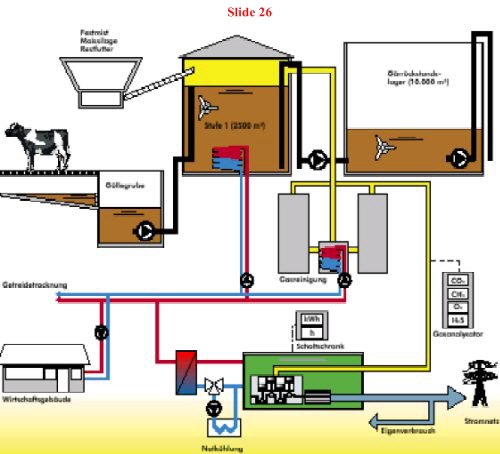

An example of an Agricultural Anaerobic Digestion Plant Design

Slide 26, above, appears to have been produced by Entec GMBh, with the following design data given on the same slide:

- Substrates: cattle manure, corn

- Input: 801 Mg/week (fresh)

- TSS = 6,6 kg/Mg

- VSS = 5,3 kg/Mg

- Reactor volume: 2500 m³

- Detention time: 20 d

- Volume Load:

- Br = 2,5 kg VSS/m³d

- Yields:

- Electric Power: 40655 kWh/week

- Thermal Power: 55435 kWh/week

[We are unable to attribute this information due to the original slides having been removed.]

Anaerobic Digestion Plant Design in More Detail

The AD process begins when biomass is put inside a sealed tank or digester Naturally occurring micro-organisms digest the biomass which releases a methane-rich gas, known as biogas that's used to generate renewable heat and power. via www.balmoraltanks.com

The primary purpose of AD plant design is normally to produce biogas efficiently, and the following assumes this purpose throughout. (More information is here for AD plants for water treatment.)

Common AD Plant Design Configurations

There are various ways that anaerobic digesters can be built so that they can work efficiently. These include:

- batch vs. continuous process mode,

- mesophilic vs. thermophilic temperature conditions,

- high vs. low solids content, and

- single stage vs. multi-stage processes.

- Above this level is considered high solids content and can also be known as dry digestion.

In the most common single-stage process, one reactor houses the four anaerobic digestion steps.

Batch or Continuous Processes

Anaerobic digestion can be performed as a batch process or a continuous process. In a batch system, biomass is added to the reactor at the start of the process. The reactor is then sealed for the duration of the process. In its simplest form, batch processing needs inoculation with already processed material to start the anaerobic digestion.

In continuous digestion processes, organic matter is constantly added (continuously completely mixed) or added in stages to the reactor (continuous plug flow; first in, first out). Here, the end products are constantly or periodically removed, resulting in constant production of biogas. A single or multiple digesters in sequence may be used.

Mesophilic and Thermophilic Digestion

Mesophilic digestion takes place optimally around 30 to 38 °C, or at ambient temperatures between 20 and 45 °C, where mesophiles are the primary microorganism present. Thermophilic digestion takes place optimally around 49 to 57 °C or at elevated temperatures up to 70 °C, where thermophiles are the primary microorganisms present.

Operation at higher temperatures facilitates greater pathogen reduction of the digestate.

Feedstock Pre-treatment in AD Plant Design

Additional pre-treatment can be used to reduce the necessary retention time to produce biogas. For example, certain processes shred the substrates to increase the surface area or use a thermal pretreatment stage (such as pasteurisation) to significantly enhance the biogas output. The pasteurisation process can also be used to reduce the pathogenic concentration in the digestate leaving the anaerobic digester. Pasteurisation may be achieved by heat treatment combined with maceration of the solids.

High and Low Solids Biogas-Digester Variants

High solids (dry) digesters are designed to process materials with a solids content between 25 and 40%. Unlike wet digesters that process pumpable slurries, high solids (dry–stackable substrate) digesters are designed to process solid substrates without the addition of water. The primary styles of dry digesters are continuous vertical plug flow and batch tunnel horizontal digesters. Continuous vertical plug flow digesters are upright, cylindrical tanks where feedstock is continuously fed into the top of the digester and flows downward by gravity during digestion.

High Solids Batch Tunnel Anaerobic Digesters

In batch tunnel digesters, the feedstock is deposited in tunnel-like chambers with a gas-tight door. Neither approach involves mixing inside the digester. The amount of pretreatment, such as contaminant removal, depends both upon the nature of the waste streams being processed and the desired quality of the digestate. Size reduction (grinding) is beneficial in continuous vertical systems, as it accelerates digestion, while batch systems avoid grinding and instead require structure (e.g. Continuous vertical dry digesters have a smaller footprint due to their shorter effective retention time and vertical design.

High Solids (wet) Digesters

High solids (wet) digesters process a thick slurry that requires more energy input to move and process the feedstock. The thickness of the material may also lead to associated problems with abrasion. High solids digesters will typically have a lower land requirement due to the lower volumes associated with moisture.

Low Solids (wet) Digesters

Low solids (wet) digesters can transport material through the system using standard pumps that require significantly lower energy input. Low-solids digesters require a larger amount of land than high-solids digesters due to the increased volumes associated with the increased liquid-to-feedstock ratio of the digesters. There are benefits associated with operation in a liquid environment, as it enables more thorough circulation of materials and contact between the bacteria and their food.

Anaerobic Lagoons

Another one-stage reaction system is an anaerobic lagoon. These lagoons are pond-like, earthen basins used for the treatment and long-term storage of manures. Here the anaerobic reactions are contained within the natural anaerobic sludge contained in the pool.

Two-stage Digestion System Design

In a two-stage digestion system (multistage), different digestion vessels are optimised to bring maximum control over the bacterial communities living within the digesters. Acidogenic bacteria produce organic acids and more quickly grow and reproduce than methanogenic bacteria. via en.wikipedia.org

When to Choose a Thermophilic Anaerobic Digestion Design

Generally, thermophilic anaerobic digestion (AD) is used when a greater pathogen kill is necessary. This temperature range can produce “Class A Biosolids”. Class A Biosolids is a designation for dewatered and heated sewage sludge that meets U.S. EPA guidelines for land application with no restrictions. Thus, Class A Biosolids can be legally used as fertilizer on farms, and vegetable gardens, and can be sold to home gardeners as compost or fertilizer. Thermophilic digesters require less time to process feedstocks but may have higher costs and be more difficult to operate.

In general, mesophilic digesters are easier to operate and maintain, but will not result in sufficient pathogen kill to produce Class A Biosolids. via www.epa.gov

Anaerobic Digestion Design for Pumping and Mixing the Sludge

Irrespective of a single or two-stage digestion system, in general, the frequency of pumping the sludge to the digester needs to be standardized so that uniformity of digestion rate can be maintained. Further, mixing (using, for example, mechanical or gas mixers or recirculation pumps) is necessary to prevent the stratification of sludge in the digester, which can affect performance.

In conventional digesters, mixing is intermittent and, therefore, the likelihood of stratification is higher and the holding times can vary from 30 to 60 days. These have a slower rate of digestion. In comparison, modern digesters have a high turnover and digestion rate due to the provision of continuous mixing and streamlined sludge feeding and withdrawal systems. The holding times in such digesters can be as low as 15 days.

Many digesters also have floating covers to accommodate the gas produced. Such gas can be transferred to be used for heating the sludge to necessary levels. It can also be used elsewhere, for example, for domestic purposes. via chokhavatia.com

Frequently Asked Questions: Anaerobic Digestion Plant Design

What is Anaerobic Digestion Plant Design?

Anaerobic Digestion (AD) Plant Design focuses on defining the primary aim or purpose an AD Plant is intended to satisfy. This could range from biogas production to waste treatment.

How Do You Set the Brief for an Anaerobic Digestion Project?

The main purpose for Anaerobic Digestion in Municipal Solid Waste (MSW) Treatment might be to reduce the mass of the material, along with biogas biofuel production, sanitization, and producing a digestate useful for various purposes.

What Does Anaerobic Digestion Design Encompass?

Anaerobic Digestion Plant Design is a generic term used to encompass the various purposes AD plants serve, beyond just biogas production. It includes waste treatment and the digestion of sludge from water treatment processes.

What Are Common AD Plant Design Configurations?

AD plants can operate under various configurations such as batch vs. continuous process mode, mesophilic vs. thermophilic temperature conditions, and single stage vs. multistage processes.

What's the Difference Between Batch and Continuous Processes in AD?

Anaerobic digestion can be executed in batch mode or as a continuous process, affecting the production and removal of biogas and digestate.

What Are Mesophilic and Thermophilic Digestion?

These terms refer to the optimal temperature ranges for the digestion process, influencing pathogen reduction and the efficiency of the digestion process.

How Important is Feedstock Pre-treatment in AD Plant Design?

Pre-treatment methods can enhance biogas output and reduce pathogen concentration in the digestate, including mechanical and thermal pretreatment.

What Are the Differences Between High and Low Solids Designs for Biogas-Digesters?

Digesters can be designed to process materials of varying solid content, affecting the process's energy input, land use, and operational challenges.

Why Choose Thermophilic Anaerobic Digestion Design?

Thermophilic AD is preferred when a greater pathogen kill is necessary, producing “Class A Biosolids” that can be safely used as fertilizers.

What Design Considerations Are There for Pumping and Mixing the Sludge in AD Design?

Effective sludge management through standardized pumping and mixing prevents stratification and optimizes the digestion rate.

Hi there I am so excited I found your blog, I would just like to say kudos for this fantastic post and a all round interesting blog. Would you please provide more information about the rural community biogas in Kenya, and kind people to help us. Website you want is my cousin’s.

Fantastic post, very much useful information for a new starter in anaerobic digestion plant design. It is really a hidden gem. I found your blog a few days ago from a Google search and have been reading it over the past few days.